Sizes of steel pipes table of standard sizes. Sizes of metal pipes and their effect on application features

In this article, we will talk about what diameter metal pipes are and how these or those standard sizes affect their throughput and scope.

The topic of the article is relevant, since standard sizes are exactly the parameter that determines where the rolled metal will be used, what throughput it will be characterized by, and what media can be transported through it. Again, the sizes are of particular importance because the price of the product is determined in accordance with these parameters.

Application features in accordance with standard sizes

For a long time, large-diameter metal pipes, as well as their small-sized counterparts, have been used in a variety of industrial fields and various areas of human economic activity.

Rolled metal with a radial cross-sectional configuration is widely used in construction, in the chemical and food industries, in agriculture in the automotive industry, etc. Of course, this list of applications is incomplete, but even looking at it, one can understand that this type of metal products is very popular, and therefore it is presented on the market with a wide selection of dimensions and configurations.

Currently, welded, seamless, seamless varieties of rolled steel with round section... The welded modification is characterized by simplicity of industrial production, and therefore its price is more affordable. Seamless products are more expensive, but they are more reliable, as they demonstrate high resistance to mechanical stress.

For greater durability, products made of ferrous metals are treated by galvanizing. Regardless of the methods of processing the inner surface, metal pipes have a lower throughput compared to polymer analogues.

The most important parameter to consider when selecting and subsequent use of pipes is the cross-sectional size. The diameters of metal pipes must correspond to the size of the connecting fittings, with the use of which the assembly of water supply and heating pipes is carried out.

Internal and external dimensions of the section

The difference between the internal size of the cross section and the external one is determined by the wall thickness. The thicker the wall, the more the outer diameter will differ from the inner diameter from each other. Conversely, the thinner the wall, the smaller the difference.

That is why, when choosing components for self-assembly of certain systems, attention is primarily paid to the dimensions of the inner space of the pipe.

Important: The wall thickness, along with the cross-sectional parameters, is of considerable importance, since taking this value into account at the design stage, it is possible to calculate the long-term permissible load on the system.

Modern sizes and assortment of metal pipes in accordance with GOST applies to the entire range of similar products that are manufactured industrially.

Having accurate information about these parameters, you can not only select fittings and other accessories of the appropriate size, but also correctly perform design calculations for the construction of systems for transporting a particular medium. Moreover, having data on the external and internal dimensions of the section, it is possible to design other systems, taking into account the presence of weaknesses and their subsequent elimination.

Traditionally, the internal dimension is used in marking the parameters of steel and cast iron products. Marking on rolled copper is applied taking into account the outer diameter.

Features of standard sizes

The diameters of metal pipes are divided into the following categories:

- conditional;

- nominal;

- outdoor;

- internal.

Important: All of the above parameters are indicated in millimeters when designating domestic products and in inches when designating products of foreign production.

Standardization of sizes

The first generally accepted table of sizes of metal pipes appeared when uniform standards for connecting elements were developed, using which plumbing, sewer, heating and other systems were assembled. The introduction of standard parameters made it possible to significantly expand the scope of application of plumbing components made of steel and improve the quality of their assembly.

The emergence of uniform parameters turns into additional advantages when carrying out large-scale design of various highways, since now it is much easier for specialists involved in development and design to select connecting elements, having accurate information about the outer dimensions of pipes.

Now you can choose and purchase a variety of bends, transitions, plugs, tees and shut-off valves knowing just one inner diameter. As a result, both an experienced specialist and a novice plumber can cope with the assembly of a plumbing or heating.

Classification according to GOST

Let's find out how a 100 mm metal pipe differs from similar products with other dimensions.

In accordance with the regulations prescribed in the relevant state standards, plumbing components made of steel and metal alloys are classified according to the following indicators:

- Outside diameter:

- up to 102 mm - products of small value;

- 102-530 mm - products of average value;

- 530-1420 mm - products of great importance.

- Wall thickness to diameter ratio:

- modifications with particularly thin walls;

- modifications with thin walls;

- modifications with medium wall thickness (normal products);

- thick-walled modifications;

- modifications with especially thick walls.

Important: When installing plumbing and heating systems in residential and public buildings, they are used within 10-30 mm.

Selection according to dimensions

Now let's try to determine what a metal pipe 32 or similar products with smaller or larger cross-sectional dimensions can be used for:

- A metal pipe 20 mm is used when installing water supply systems from a riser to a tap.

- Products with a diameter of 40 to 50 mm, as a rule, are used in the construction of centralized systems of cold and hot water supply, as well as heating in residential buildings.

- Products with a cross-sectional area of \u200b\u200b150 mm are used to create water supply systems for household and industrial purposes.

- Products with a diameter of 273 mm have found wide application in solving a wide range of tasks typical for the chemical and oil industry.

- Galvanized steel products with a size of 325 mm or more are an excellent solution for complex centralized heating systems.

- Galvanized steel products with dimensions of 530-1020 mm are in demand when transporting liquid combustible media, such as natural gas and refined products.

- Products with an inner diameter of 630 mm are used in construction for the construction of complex frame elements, industrial water drainage systems, etc.

Output

So, now you know what is the instruction for selecting and using pipes in accordance with their standard sizes. Given the variety of plumbing components and related accessories available on the market, the findings will be useful and practical.

Do you have questions that require clarification? In this case, more useful information can be obtained by watching the video in this article.

Modern life is such that at least once, but every person is faced with the problem of equipping the water supply system or replacing pipes. And if you are not an expert in this business, then it is very easy to get lost in the vast market supply.

No matter, whether you will do the work yourself or will it be done by professionals, you still need to knowwhat are the sizes of plumbing steel pipes.

- inner diameter, it is the main conditional characteristic of water supply pipes and connecting nodes;

- Dy is the diameter of the conditional transition, it is the nominal value of the inner diameter, expressed in millimeters. The value can be rounded;

- Dn is the nominal diameter;

- pipe wall thickness;

- outer diameter.

Pipe diameter

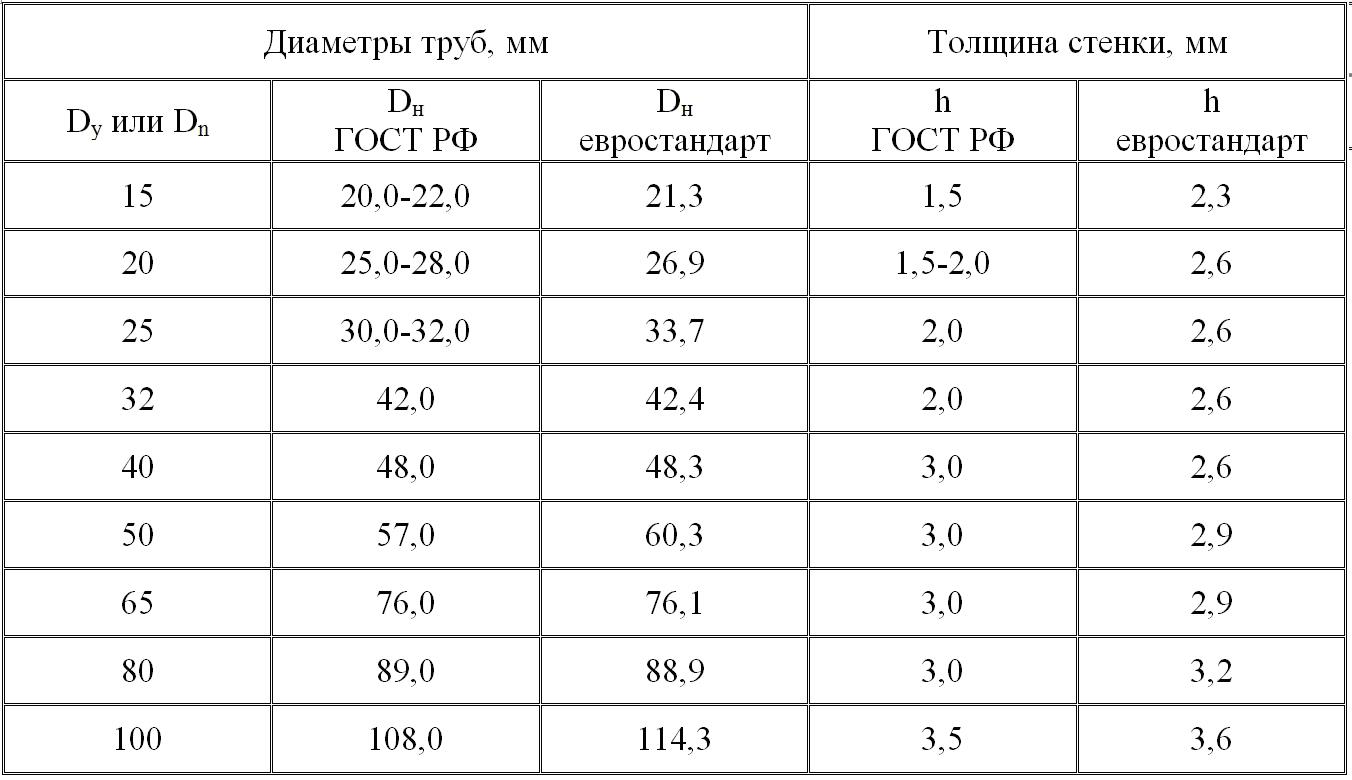

The main dimensional characteristic of steel pipes is their diameter. The classification of products by this parameter makes it possible to carry out design calculations for the transportation of a certain substance through a pipeline. Below is the steel pipe size table:

Pipe diameter - table

Standard sizes of pipes

It turns out that the diameter of steel pipes for plumbing, it is customary to measure in inches on the inner diameter... For example, if we are talking about an inch pipe, then its inner diameter is equal to an inch, that is, approximately 25.4 mm. But what about the outer diameter?

The plumber needs him, because when arranging the water supply network, you cannot do without threaded connections, and the threads on the pipes are cut from the outside.

For this, a rather original way was found, and a special thread system was developed for the outer diameters of water pipes. This system is called pipe thread. The originality lies in the following: for example, you know that the M10 metric thread has an outer diameter of 10 mm, but the pipe thread is completely different. For a half-inch pipe, the outer diameter is slightly less than 21 mm, with the same diameter there will be a thread cut on it.

The pipe is called half-inch in internal diameter, but the word "pipes" is added. Therefore, the standard sizes of steel pipes in this case will be determined by the following designation: ½ "pipes."

Below is a table of steel pipes for water supply with dimensions that are produced by the industry:

Pipe sizes - table

Standard pipe diameters

The diameters of steel pipes are regulated by GOST 10704-91. Conditionally standard sizes pipes by their diameter are divided into three categories:

- small diameter - from 10 to 114 mm;

- average diameter - from 114 to 530 mm;

- diameter large - more than 530 mm.

The pipes with the smallest diameter are used for the plumbing system at the end points of consumption. Medium diameters are preferred for urban plumbing and industrial crude oil recovery systems. Large-diameter pipes are used in the construction of gas and oil trunk pipelines.

In their shape, pipes can be not only round, but also oval, rectangular, square. Despite such a variety in the shape of the section, all pipes have basically two types of parameters: technical and geometric. The geometric dimensions of pipes are represented by characteristics such as outside diameter, wall thickness or the ratio of outside and inside diameters, and length. , that is, the dimensions of the pipes are standardized by state standards (GOST). Various GOSTs are developed for pipes not only with different ways manufacture, but also for different materials used in the manufacture of pipes. In the Russian market, it is generally accepted to indicate pipe dimensions in mm (millimeters), but you can also find pipe dimensions in inches. The latter are most often indicated for imported pipes. The length of rolled pipes is usually measured in meters.

The most common and popular are the following pipe sizes (diameter from larger to smaller): 1420, 1220, 1020, 920, 820, 720, 530, 426, 377, 325, 273, 219, 159. This rolled product refers to pipes of large and medium diameter. Smaller diameters are much less in demand on the market, so you can certainly find them, but you have to try. On the manufacturer's website, there will definitely be a table of pipe sizes that the company makes. Usually, any manufacturer tries to cover as wide a range of pipe sizes as possible, since nowadays the demand market for this type of rolled steel is very wide.

Until recently, Russian production did not produce seamless pipes with a diameter of more than 426 mm. But electrowelded covers almost the entire range. Spiral welded pipes can have a diameter greater than 1420, but less than 159 - not available. With longitudinal seam pipes, things are different. According to GOST, the smallest diameter of a longitudinal welded pipe is 8 mm, and the largest is 1420 mm. This is due to the fact that spiral and longitudinal welded pipes have a different manufacturing method, although both of them belong to welded pipes.

Pipe sizes are not limited to one diameter. Wall thickness is also one of the important technical indicators. Moreover, the diameter directly affects the size of the pipes, such as the wall thickness. The larger diameter allows the production of pipes with a wider range of wall thicknesses. For example, if the dimensions of longitudinal metal pipes (or rather, their diameter) are 530 cm, then the wall thickness can vary from 5 to 24 mm. The outer transverse dimensions of longitudinal steel pipes of 1020 mm make it possible to manufacture them with a wall thickness of 8 mm to 32 mm. The most popular are for pipes with a diameter of 530 mm such wall thicknesses as 7, 8, 9 and 10 mm. For a pipe with a diameter of 1020 mm, the most common thicknesses are 10, 11, 12, and 14 mm.

It is interesting that the dimensions of GOST pipes allow manufacturers to violate certain limits. In particular, for a longitudinal welded pipe with a diameter of 1020 mm, the deviation of the wall thickness can reach almost 1 mm. More precisely - 0.8 mm, both in the direction of greater and in the direction of lesser thickness. And since the assortment of pipes is determined in increments of 1 mm in thickness, this value is quite significant. For example, when buying a pipe with a thickness of 11 mm, do not be surprised that when measured directly, it will turn out to be a pipe with walls of 10 or 12 mm. This aspect has a very great importance when buying pipes, since the weight of the rolled product depends on such a pipe size as the wall thickness. More weight - more price. Why is it customary to indicate weight, not footage? Because the cost of a pipe mainly depends on the raw materials (the so-called price-forming raw material component).

Of course, weighing a pipe is too troublesome. Therefore, when calculating the price, the theoretical weight is taken into account, which is calculated by the formula: weight of 1 running meter \u003d 0.02466 * wall thickness * (diameter-wall thickness). The wall thickness is taken in millimeters. In practice, the calculation is carried out as follows: the buyer measures the thickness of the pipes with a micrometer in order to check the deviation from the permissible values. When loading with a tape measure, the longitudinal dimensions of the pipes (i.e., length) are measured and then, having calculated the theoretical weight of 1 running meter. multiply it by the total length of the pipes.

In relation to such dimensions of steel pipes, as well as to the dimensions of pipes made of any other material, the requirements of GOSTs are quite loyal. For example: "pipes with a diameter of over 152 mm are made with a length of at least 5 m." Therefore, despite the fact that used pipes are cut a little before sale, it is impossible to distinguish them in length from new ones. It is worth remembering that many when selling straight or spiral pipes do not indicate the length. This means that the length of the pipes corresponds to GOST (usually about 11 meters). If the price list (announcement) indicates that pipes are sold cut at the seams, then their lengths are also within the limits allowed by GOSTs. Seamless pipes are allowed to be made of unmeasured length - from 4 meters to 12.5 meters. Therefore, when purchasing pipes, be interested in GOSTs.

Steel pipe diameters

The diameter of a steel pipe is determined by the outer diameter for electric-welded and seamless pipes, and for vgp - by the nominal diameter (often referred to as DN). I.e, inner pipe diameter - Du, outer diameter of pipes Dн, thread diameter - G... Pipes are sized in millimeters, but WGP pipes are often denoted in inches (").

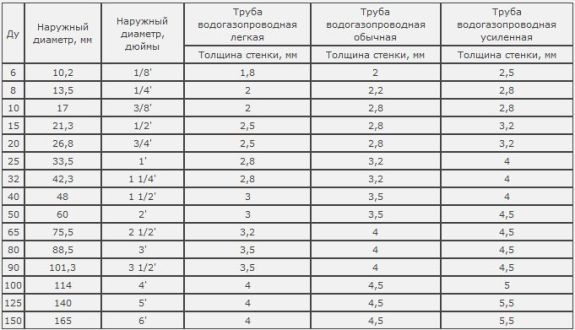

VGP pipe size (GOST 3262-75)

Main pipe dimensions: 15mm (1/2 ""); 20mm (3/4 "); 25 mm (1 "); 32 mm (1 1/4" inch and a quarter); 40 mm (1 1/2 "); 50 mm (2"). There are also the following DN: 10 mm, 65 mm, 80 mm, 90 mm, 100 mm and even 125 mm - but they are rarely used and, as a rule, are replaced by other types of steel pipes (for example, electrowelded). Most often, pipes are used for risers 3/4 ", for internal distribution 1/2".

Electric pipes (GOST 10704-91)E / s longitudinal welded pipes are of the following outer diameters (in millimeters): 10; 12; thirteen; fourteen; sixteen; 17; 17.5; eighteen; 19; 20; 21.3; 22; 24; 25; 26; 28; thirty; 32; 33; 33.7; 36; 38; 40; 42; 43; 45; 48; 51. For diameters up to 57 mm, VHP pipe appropriate size. The most popular are longitudinal welded pipes in accordance with GOST 10704-91 in sizes from 57 mm and above. Their main diameters: 57; 60; 63.5; 76; 89; 102; 108; 114; 127; 133; 140; 146; 159; 168; 178; 193; 219; 245; 273; 325; 377; 426; 530.

Welded pipes for gas and oil pipelines (GOST 20295-85)They start with a diameter of 159 mm and up to 530 mm come with the same dimensions as pipes in accordance with GOST 10704-91. Major larger diameters (in millimeters): 630, 720, 820, 1020, 1220, 1420.

Seamless hot-smoked pipes size (GOST 8732-78)Commonly used hot-rolled seamless pipe diameters (mm): 32; 38; 42; 45; 51; 54; 57; 60; 63,5; 68; 70; 73; 76; 83; 89; 95; 102; 108; 114; 121; 127; 133; 140; 146; 152; 159; 168; 180; 194; 203; 219; 245; 273; 325; 351; 426.

Manufacturing plants can produce any size of pipes at the request of the customer.

Internal pipe diameters

According to the standard series adopted in most countries, pipes have the following inner diameters, measured in mm: 6, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 200, etc.

The system of measurement by thread diameter in inches is also used. 1 "\u003d 25.4 mm.

The table shows pipe dimensions (diameters) in mm and inches:

|

Nominal pipe diameter (Dy) mm |

Thread diameter (G), inch |

Outside diameter pipes (Dн), mm |

||

|

Steel water and gas pipe |

Seamless |

Polymer |

||

When installing a steel pipe system for residential buildings, pipes with an inner diameter of Dy \u003d 15, 20 and 32 mm are usually used.

Cast iron gravity pipes with a diameter of Dу \u003d 50 and 100 mm are the most commonly used.

At present, pipes made of polymeric materials are increasingly used for laying indoor pipelines, which are replacing cast iron and steel.

It should be noted that, depending on the type of material used in the manufacture of pipes, different designation systems are used. In most cases, steel and cast iron pipes are designated by nominal bore or internal diameter. Copper pipes, some types of steel pipes, pipes made of polymeric materials are designated by the outer diameter. Therefore, you should carefully consider the choice of the required pipe, as well as take into account the wall thickness.

Outside pipe diameters and pipe wall thickness

|

Outer diameter, Dн mm |

Wall thickness, mm |

|||||

|

Steel pipes for water and gas supply GOST 3262-75 |

||||||

|

Electric-welded steel pipes GOST 10704-91 GOST 10705-80 |

||||||

|

Plastic pipes |

||||||

When drafting highways for the transportation of combustible and non-aggressive compounds in the mining industry, utilities, construction and mechanical engineering, standard indicators are taken into account, according to which a steel pipe is selected - diameters (table). The price per meter depends on the parameters of products that meet the requirements of GOST and TU:

- Inner diameter.

- Nominal passage of the pipeline (Dy). Internal section ratings (mm) rounded up.

- Nominal diameter (Dn).

- External parameters.

- Metal thickness.

Internal parameters

It determines the correct choice of nodes and fittings, with constant indicators of the external section, it may differ due to the wall thickness. To calculate the inner diameter, use the formula:

Dvn \u003d Dn - 2S

To standardize the dimensions, a conventional designation is used - Dу (nominal internal diameter, rounded up), which allows classifying steel pipes of different types. Diameter, wall thickness, table of measured and multiple dimensions of the length of VGP structures are determined by GOST 355-52. Based on the thickness of the rolled products, pipes are classified into light, ordinary and reinforced:

According to GOST 326275, which determines the technical parameters of steel VGP products, this category includes structures with a cylindrical thread, rolled, cut or without thread. It is possible to hide up to 10% of the internal section of pipes with a thread. By agreement with the consumer, the thread is applied to one or both sides of the structures, if their diameter is from 1 cm.

External parameters

When classifying products into large, small and medium sizes, the outer (Dn) diameters of steel pipes are used. The size table defines the standard metric indicators according to GOST 10704-91:

The most popular are pipes with parameters:

The small outer section determines the use of pipes for arranging the water supply system in residential buildings, offices, shops, etc. The middle section is used for urban communications and industrial purposes. Large-sized items are required for the installation of gas and oil pipelines.

Pipe sizes in inches

Inch dimensions of steel pipes are used to measure water and gas lines. The table of standard sizes has discrepancies with metric parameters, which is caused by measuring pipes not by the outer, but by the inner diameter, depending on the wall thickness (one inch is equal to 25.4 - 27.1 mm) and thread.

For example, the parameters of unthreaded pipes take the following form:

- The inner section of 0.5 inch structures is 12.7 mm.

- Internal section of structures 3/4 \u003d 19 mm.

- For an internal section of 2 inches, this figure is 50.8 mm.

For threaded pipes, these indicators will take the following form:

- Design 0.5 in. - 20.4-20.7 mm.

- 3/4 in. Pipeline - 25.9-26.2 mm.

- Product in 2 in. - 57.9-58.3 mm.

If the parameters of the contours are known, you can quickly and accurately select accessories for joining the product, determine the throughput and the dependence of the dimensions on the production technology. There are steel pipes with a throughput (DN) of 6-150 mm and more. The most popular are designs with a section of 15-80 mm.

For approach water pipes Usually, rolled products with a diameter of 10 and 15 mm are chosen, which in translation is 3/8 in. and 1/2 in. When installing a riser, the inner section of the pipes is 20 and 25 mm, which is 3/4 and 1 inch.

For joining with plastic products, standard adapters are used, taking into account the dimensions of the pipe metal roll and the material for production. When connecting copper and aluminum circuits, it should be noted that their production is regulated by metric standards. This requires taking into account the real metric external and internal parameters of the products.

The length of the pipes varies within 4-12 m and is determined by three parameters:

- Measured.

- Unmeasured.

- Multiple measurements.

- Category "B" - Normal Accuracy.

- Category "A" - high accuracy.

The cost of gas pipelines is determined by the presence of galvanizing. The protective coating provides resistance to corrosion and increases the service life. But, galvanized pipes have an increase in mass of 3%, which increases the total weight of the batch.

Weight calculation

To determine the mass of 1 running m, the formula is used:

![]()

m - weight of 1 meter meter of the pipeline (U / v.)

Pi \u003d 3.14 (constant).

d - outer section in mm.

s - metal thickness, mm.

R - specific gravity of steel in g / cu. cm.

The weight of one meter of a pipe is calculated in the assortment, with a specific gravity of steel \u003d 7.85 g / cm3. Galvanized pipes weigh 3% more.

Dependence of dimensions on production technology

Classification of standard parameters steel structures produced based on manufacturing technology. This makes it possible to cover the entire "model range" of rental. There are 4 main assortments in total:

Dimensions of hot rolled pipes

This category includes products with a cross section in the range of 20 - 550 mm. More than 80 types of products are divided according to the outer diameter, according to GOST 873278. Taking into account the difference in wall thickness, the range of structures is significantly expanding. For example, pipes with a cross section of 25 mm include 15 types of structures with a metal thickness of 2.5 - 8 mm.

Parameters of cold rolled pipes

Cold rolled pipelines include products with a cross section of 5 - 250 mm. According to GOST 873475, the line of external diameters includes 70 types. The type of internal section depends on the wall thickness: 0.3 - 24 mm. This standard defines more than 20 types of pipes with an external section of 50 mm: metal thickness 1.2 - 8 mm.

Longitudinal seam diameter

The tabular data with the dimensions of longitudinal welded pipes are presented in the range of 10 - 1420 mm. GOST 1070491 includes the widest assortment, where there are more than 80 designs.

Welded pipes are graded along the thickness of the metal, which allows you to select the desired value between 1 and 32 mm. The range includes 12 types of products, 60 mm each.

The length of the pipes depends on the following indicators:

Unmeasured length:

- D (diameter) up to 3 cm - L (length) up to 2 m.

- D from 3 - 7 cm - L from 3 m.

- D 7 ... 15.2 cm - L from 4 m.

- D 152 mm - L from 5 m.

At the request of the client, pipes of class "A" and "B" according to GOST 107-05 with a cross section of 15.2 cm are produced with a length of 10 m. Structures of all categories with a cross section of up to 7 cm have a length of 4 m.

Measured length:

- D up to 7 cm - L 5 ... 9 m.

- D 7 ... 21.9 cm - L 6 ... 9 m.

- D 21.9 ... 42.6 cm - L 10 ... 12 m.

If the cross-section of pipes exceeds 42.6 cm, they are supplied in custom lengths only. Upon agreement with the customer, pipes are produced in the range of 7 ... 219 cm, the maximum length of structures is determined by the range from 6 to 12 m.

The length in multiples of 25 cm within the lower limit for measuring pipes is increased by an allowance for a cut of 5 mm.

Parameters of spiral seam welded pipes

The main requirements for the production of pipes are regulated by GOST 869674, which describes 21 types of structures with a range of sizes from 159 to 2520 mm. The range includes large-sized products with small wall thicknesses. So, the smallest pipe with a cross section of 159 mm has a metal thickness of 3.5 mm. And the structure with a maximum dimensions of 252 cm is made using a steel strip with walls of 25 mm.

Purpose of pipes

Depending on the place of laying or on the requirements, pipes are distinguished for general and special purposes.

The first option is used for highways that do not have strict requirements. Such structures are used for the transportation of non-aggressive compositions and bulk materials. They are successfully used in the creation of fences, supports, assembly hoses and an irrigation system.

Seamless hot-rolled structures in accordance with GOST 873278 are manufactured with a diameter range of 20 - 550 mm. Cold-rolled structures in accordance with GOST 873475 correspond to the size range:

- Products with a minimum wall section (0.3 to 6 mm) and an outer circumference of 5 to 250 mm.

- Thin sheet with an outer diameter: 5 - 250 mm, metal section 0.6 - 20 mm.

- Thick-walled pipes with parameters: 6 - 250 mm, metal cross-section 1.6 - 24 mm.

- Powerful structures with a metal section of 2 - 12 cm and dimensions: 6 - 70 cm.

Seamless hot-rolled products with corrosion resistance in accordance with GOST 994081 and are produced in the range of sizes 76 - 325 mm, wall thickness 3.5 - 28 mm.

Cold-rolled products are manufactured in accordance with GOST 994181. Section of structures: 5 - 250 mm. They are used for laying water mains, boiler rooms and other technical purposes. Wall thickness: 0.2 - 22 mm. Steel grades are used for manufacturing:

The production of pipes from electrowelded steel is regulated by GOST 1070580, section of structures: 10 - 530 mm. Carbon and low-alloy steel composition is used for the manufacture of pipes in accordance with GOST 1070580.

Insulated pipes

Steel pipes (GOST 307322001), produced in polyurethane foam insulation with a polyethylene coating to ensure channelless laying of heating systems underground, where the coolant has the following parameters:

- System pressure - up to 1.6 MPa.

- Heating up to 130 gr.

- Manufactured in accordance with GOST 307322001.

Based on the insulation parameters, there are 2 types of pipes:

1 - according to the standard.

2 - with amplification.

Pipes made of steel with an outer section of 57 - 1020 mm and a length of up to 12 m are used for laying insulated structures.They comply with the requirements of the regulatory documents of the manufacturing plant and state standards:

When choosing bends, tees and adapters, you need to focus on the requirements:

Conventional indicators of insulated pipes

Products with an external cross-section of 57 mm, a metal cross-section of 3 mm and an insulating polyurethane foam sheath of type 1, protected by polyethylene, have a conditional meaning:

Bare pipe marking

With an external cross-section of 76 mm, a metal cross-section of 3 mm, a measured length (2nd category of accuracy), steel grade st3sp and manufactured according to group "B" GOST 1070580, the following markings are used:

Design calculations

After reviewing the dimensions of the pipes, it is necessary to take into account their throughput and strength.

The bandwidth determines functional features plumbing system. In case of incorrect calculations, a decrease in the pressure of the transported liquid (in the case of small parameters) or material overrun when laying too large pipes is possible. Inaccurate sewer calculations will lead to overflow and leakage of liquid throughout the neighborhood.

Strength characteristics depend on the shape and section. Products with different walls are able to withstand the corresponding load. This parameter is calculated based on internal or external pressure, frame rigidity.

Steel pipe price

![]()

![]()

Wholesale and retail prices

Video