Do-it-yourself UPS repair: expert advice. How to safely repair a UPS yourself? Diagnostics and repair of uninterruptible power supplies

The complete lack of information about such common devices as uninterruptible power supplies is surprising. We are breaking through the information blockade and are starting to publish materials on their design and repair. From the article you will get a general idea of the existing types of uninterruptible power supplies and a more detailed, at the circuit diagram level, about the most common Smart-UPS models.

The reliability of computers is largely determined by the quality of the electrical network. The consequences of power outages such as surges, rises, dips and loss of voltage can include keyboard locking, data loss, damage to the system board, etc. To protect expensive computers from troubles associated with the power network, uninterruptible power supplies (UPS) are used. A UPS allows you to get rid of problems associated with poor quality power supply or its temporary absence, but is not a long-term alternative source of power supply, like a generator.

According to the SK PRESS expert and analytical center, in 2000 the sales volume of UPS on the Russian market amounted to 582 thousand units. If we compare these estimates with data on computer sales (1.78 million units), it turns out that in 2000, every third computer purchased was equipped with an individual UPS.

The vast majority of the Russian UPS market is occupied by products from six companies: APC, Chloride, Invensys, IMV, Liebert, Powercom. APC products have been maintaining a leading position in the Russian UPS market for many years now.

UPSs are divided into three main classes: Off-line (or stand-by), Line-interactive and On-line. These devices have different designs and characteristics.

Rice. 1. Block diagram of an Off-line class UPS

The block diagram of an Off-line class UPS is shown in Fig. 1. During normal operation, the load is supplied with filtered mains voltage. To suppress electromagnetic and radio frequency interference in input circuits, EMI/RFI Noise filters are used on metal-oxide varistors. If the input voltage becomes lower or higher than the set value or disappears altogether, the inverter is turned on, which is normally in the off state. By converting the DC voltage of the batteries into alternating voltage, the inverter powers the load from the batteries. The shape of its output voltage is rectangular pulses of positive and negative polarity with an amplitude of 300 V and a frequency of 50 Hz. Off-line class UPSs operate uneconomically in electrical networks with frequent and significant voltage deviations from the rated value, since frequent switching to battery operation reduces the battery life. The power of the Back-UPS model Off-line class UPS produced by APC is in the range of 250...1250 VA, and the Back-UPS Pro model is in the range of 2S0...1400 VA.

Rice. 2. Block diagram of Line-interactive class UPS

The block diagram of a Line-interactive class UPS is shown in Fig. 2. Just like Off-line UPSs, they retransmit alternating mains voltage to the load, while absorbing relatively small voltage surges and smoothing out interference. The input circuits use Metal Oxide Varistor EMI/RFI Noise Filter to suppress EMI and RFI. If an accident occurs in the power grid, the UPS synchronously, without loss of the oscillation phase, turns on the inverter to power the load from the batteries, while the sinusoidal shape of the output voltage is achieved by filtering the PWM oscillation. The circuit uses a special inverter to recharge the battery, which also works during power surges. The range of operation without connecting a battery is expanded due to the use of an autotransformer with a switchable winding in the input circuits of the UPS. The switch to battery power occurs when the mains voltage goes out of range. The power of Line-interactive UPS class Smart-UPS manufactured by APC is 250...5000 VA.

Rice. 3. Block diagram of an On-line class UPS

The block diagram of an On-line class UPS is shown in Fig. 3. These UPSs convert AC input voltage to DC, which is then converted back into AC with stable parameters using a PWM inverter. Since the load is always supplied by the inverter, there is no need to switch from the external network to the inverter, and the switching time is zero. Due to the inertial DC link, which is the battery, the load is isolated from network anomalies and a very stable output voltage is generated. Even with large deviations in input voltage, the UPS continues to supply the load with pure sinusoidal voltage with a deviation of no more than +5% from the user-set nominal value. APC On-line class UPSs have the following output powers: Matrix UPS models - 3000 and 5000 VA, Symmetra Power Array models - 8000, 12000 and 16000 VA.

Back-UPS models do not use a microprocessor, but Back-UPS Pro, Smart-UPS, Smart/VS, Matrix and Symmetna models do use a microprocessor.

The most widely used devices are: Back-UPS, Back-UPS pro, Smart-UPS, Smart-UPS/VS.

Devices such as Matrix and Symmetna are used primarily for banking systems.

In this article, we will look at the design and circuit of Smart-UPS 450VA...700VA models used to power personal computers (PCs) and servers. Their technical characteristics are given in table. 1.

Table 1. Technical characteristics of Smart-UPS models from APC

| Model | 450VA | 620VA | 700VA | 1400VA |

|---|---|---|---|---|

| Allowable input voltage, V | 0...320 | |||

| Input voltage when operating from the network *, V | 165...283 | |||

| Output voltage *, V | 208...253 | |||

| Input circuit overload protection | Resettable circuit breaker | |||

| Frequency range when operating from mains, Hz | 47...63 | |||

| Switching time to battery power, ms | 4 | |||

| Maximum load power, VA (W) | 450(280) | 620(390) | 700(450) | 1400(950) |

| Output voltage when operating on battery, V | 230 | |||

| Frequency when operating on battery power, Hz | 50 ± 0.1 | |||

| Waveform when running on battery | Sine wave | |||

| Output circuit overload protection | Overload and short circuit protection, latching switch off when overloaded | |||

| Battery Type | Lead sealed, maintenance free | |||

| Number of batteries x voltage, V, | 2 x 12 | 2 x 6 | 2 x 12 | 2 x 12 |

| Battery capacity, Ah | 4,5 | 10 | 7 | 17 |

| Battery life, years | 3...5 | |||

| Full charge time, h | 2...5 | |||

| UPS dimensions (height x width x length), cm | 16.8x11.9x36.8 | 15.8x13.7x35.8 | 21.6x17x43.9 | |

| Net weight (gross), kg | 7,30(9,12) | 10,53(12,34) | 13,1(14,5) | 24,1(26,1) |

* User adjustable via PowerChute software.

UPS Smart-UPS 450VA...700VA and Smart-UPS 1000VA...1400VA have the same electrical circuit and differ in battery capacity, number of output transistors in the inverter, power transformer power and dimensions.

Let's consider the parameters characterizing the quality of electricity, as well as terminology and designations.

Power problems can be expressed as:

In Russia, dips, dropouts and voltage surges, both up and down, account for approximately 95% of deviations from the norm, the rest is noise, impulse noise (needles), and high-frequency surges.

The units used to measure power are Volt-Amps (VA, VA) and Watts (W, W). They differ in power factor PF (Power Factor):

The power factor for computer equipment is 0.6...0.7. The number in the designation of APC UPS models means the maximum power in VA. For example, the Smart-UPS 600VA model has a power of 400 W, and the 900VA model has a power of 630 W.

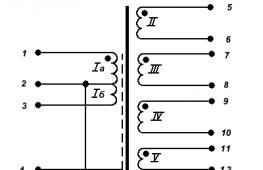

The block diagram of the Smart-UPS and Smart-UPS/VS models is shown in Fig. 4. The mains voltage is supplied to the EM/RFI input filter, which serves to suppress interference from the mains. At the rated mains voltage, relays RY5, RY4, RY3 (pins 1, 3), RY2 (pins 1, 3), RY1 are turned on, and the input voltage passes to the load. Relays RY3 and RY2 are used for the BOOST/TRIM output voltage adjustment mode. For example, if the network voltage has increased and gone beyond the permissible limit, relays RY3 and RY2 connect the additional winding W1 in series with the main winding W2. An autotransformer is formed with a transformation ratio

K = W2/(W2 + W1)

less than one, and the output voltage drops. In the event of a decrease in the mains voltage, the additional winding W1 is reversed by the relay contacts RY3 and RY2. Transformation ratio

K = W2/(W2 - W1)

becomes greater than unity, and the output voltage increases. The adjustment range is ±12%, the hysteresis value is selected by the Power Chute program.

When the input voltage fails, relays RY2...RY5 are turned off, a powerful PWM inverter powered by the battery is turned on, and a sinusoidal voltage of 230 V, 50 Hz is supplied to the load.

The multi-link power supply noise suppression filter consists of varistors MV1, MV3, MV4, inductor L1, capacitors C14...C16 (Fig. 5). Transformer CT1 analyzes high-frequency components of the network voltage. Transformer CT2 is a load current sensor. Signals from these sensors, as well as the temperature sensor RTH1, are sent to the analog-to-digital converter IC10 (ADC0838) (Fig. 6).

Transformer T1 is an input voltage sensor. The command to turn on the device (AC-OK) is sent from the two-level comparator IC7 to the base Q6. Transformer T2 - output voltage sensor for Smart TRIM/BOOST mode. From pins 23 and 24 of processor IC1 2 (Fig. 6), the BOOST and TRIM signals are supplied to the bases of transistors Q43 and Q49 to switch relays RY3 and RY2, respectively.

The phase synchronization signal (PHAS-REF) from pin 5 of transformer T1 goes to the base of transistor Q41 and from its collector to pin 14 of the IC12 processor (Fig. 6).

The Smart-UPS model uses an IC12 microprocessor (S87C654) that:

The EEPROM IC13 memory chip stores factory settings, as well as calibrated settings for frequency signal levels, output voltage, transition limits, and battery charging voltage.

Digital-to-analog converter IC15 (DAC-08CN) generates a reference sinusoidal signal at pin 2, which is used as a reference for IC17 (APC2010).

The PWM signal is generated by IC14 (APC2020) together with IC17. Power field-effect transistors Q9...Q14, Q19...Q24 form a bridge inverter. During the positive half-wave of the PWM signal, Q12...Q14 and Q22...Q24 are open, and Q19...Q21 and Q9...Q11 are closed. During the negative half-wave, Q19...Q21 and Q9...Q11 are open, and Q12...Q14 and Q22...Q24 are closed. Transistors Q27...Q30, Q32, Q33, Q35, Q36 form push-pull drivers that generate control signals for powerful field-effect transistors with a large input capacitance. The load of the inverter is the transformer winding, it is connected by wires W5 (yellow) and W6 (black). A sinusoidal voltage of 230 V, 50 Hz is generated on the secondary winding of the transformer to power the connected equipment.

Operation of the inverter in “reverse” mode is used to charge the battery with pulsating current during normal operation of the UPS.

The UPS has a built-in SNMP slot, which allows you to connect additional cards to expand the capabilities of the UPS:

The UPS has several voltages necessary for normal operation of the device: 24 V, 12 V, 5 V and -8 V. To check them, you can use the table. 2. Measure the resistance from the terminals of the microcircuits to the common wire with the UPS turned off and capacitor C22 discharged. Typical faults of Smart-Ups 450VA...700VA UPS and methods for eliminating them are given in table. 3.

Table 3. Typical faults of Smart-Ups 450VA...700VA UPS

| Brief description of the defect | Possible reason | Troubleshooting method |

|---|---|---|

| UPS does not turn on | Batteries not connected | Connect batteries |

| Bad or faulty battery, its capacity is low | Replace the battery. The capacity of a charged battery can be checked using a high beam lamp from a car (12 V, 150 W) | |

| Powerful field-effect transistors of the inverter are broken | In this case, there is no voltage at the terminals of the battery connected to the UPS board. Check with an ohmmeter and replace the transistors. Check the resistors in their gate circuits. Replace IC16 | |

| Broken flexible cable connecting the display | This problem may be caused by the flex cable terminals shorting on the UPS chassis. Replace the flexible cable connecting the display to the main board of the UPS. Check the serviceability of fuse F3 and transistor Q5 | |

| The power button is pressed in | Replace button SW2 | |

| The UPS turns on only from the battery | Fuse F3 burned out | Replace F3. Check the serviceability of transistors Q5 and Q6 |

| The UPS does not start. Battery replacement indicator lights up | If the battery is good, the UPS does not execute the program correctly. | Calibrate the battery voltage using a proprietary program from APC |

| The UPS does not connect to the line | The network cable is torn off or the contact is broken | Connect the network cable. Check the serviceability of the automatic plug with an ohmmeter. Check the hot-neutral cord connection |

| Cold soldering of board elements | Check the serviceability and quality of soldering of elements L1, L2 and especially T1 | |

| Varistors are faulty | Check or replace varistors MV1...MV4 | |

| When the UPS is turned on, the load is shed | Voltage sensor T1 is faulty | Replace T1. Check the serviceability of the elements: D18...D20, C63 and C10 |

| Display indicators are flashing | The capacitance of capacitor C17 has decreased | Replace capacitor C17 |

| Possible capacitor leakage | Replace C44 or C52 | |

| Relay contacts or board elements are faulty | Replace relay. Replace IC3 and D20. It is better to replace diode D20 with 1N4937 | |

| UPS overload | The power of the connected equipment exceeds the rated power | Reduce load |

| Transformer T2 is faulty | Replace T2 | |

| Current sensor ST1 is faulty | Replace ST1. Resistance greater than 4 ohms indicates a faulty current sensor | |

| IC15 is faulty | Replace IC15. Check voltage -8 V and 5 V. Check and replace if necessary: IC12, IC8, IC17, IC14 and inverter power field-effect transistors. Check the windings of the power transformer | |

| Battery won't charge | The UPS program is not working correctly | Calibrate the battery voltage using a proprietary program from APC. Check constants 4, 5, 6, 0. Constant 0 is critical for each UPS model. Check the constant after replacing the battery |

| The battery charging circuit is faulty | Replace IC14. Check the voltage of 8 V on the pin. 9 IC14, if it is missing, then replace C88 or IC17 | |

| Battery faulty | Replace the battery. Its capacity can be checked with a high beam lamp from a car (12 V, 150 W) | |

| Microprocessor IC12 is faulty | Replace IC12 | |

| When turned on, the UPS does not start, a clicking sound is heard | Reset circuit faulty | Check serviceability and replace faulty elements: IC11, IC15, Q51...Q53, R115, C77 |

| Indicator defect | Indication circuit is faulty | Check and replace faulty Q57...Q60 on the indicator board |

| The UPS does not work in On-line mode | Defective board elements | Replace Q56. Check the serviceability of the elements: Q55, Q54, IC12. IC13 is faulty or will need to be reprogrammed. The program can be taken from a working UPS |

| When switching to battery operation, the UPS turns off and turns on spontaneously | Transistor Q3 is broken | Replace transistor Q3 |

In the second part of the article, the On-line class UPS device will be considered,

OFF-LINE CLASS UPS DEVICE

Off-line UPSs from APC include Back-UPS models. UPSs of this class are low-cost and are designed to protect personal computers, workstations, network equipment, retail and point-of-sale terminals. The power of produced Back-UPS models is from 250 to 1250 VA. Basic technical data of the most common UPS models are presented in table. 3.

Table 3. Basic technical data of Back-UPS class UPS

| Model | BK250I | BK400I | BK600I |

|---|---|---|---|

| Rated input voltage, V | 220...240 | ||

| Rated network frequency, Hz | 50 | ||

| Energy of absorbed emissions, J | 320 | ||

| Peak surge current, A | 6500 | ||

| IEEE 587 Cat. Voltage Surge Values Missed in Normal Mode. A 6kVA, % | <1 | ||

| Switching voltage, V | 166...196 | ||

| Output voltage when operating from batteries, V | 225 ± 5% | ||

| Output frequency when operating from batteries, Hz | 50 ± 3% | ||

| Maximum power, VA (W) | 250(170) | 400(250) | 600(400) |

| Power factor | 0,5. ..1,0 | ||

| Crest factor | <5 | ||

| Nominal switching time, ms | 5 | ||

| Number of batteries x voltage, V | 2x6 | 1x12 | 2x6 |

| Battery capacity, Ah | 4 | 7 | 10 |

| 90% recharge time after discharging to 50%, hour | 6 | 7 | 10 |

| Acoustic noise at a distance of 91 cm from the device, dB | <40 | ||

| UPS operating time at full power, min | >5 | ||

| Maximum dimensions (H x W x D), mm | 168x119x361 | ||

| Weight, kg | 5,4 | 9,5 | 11,3 |

The index “I” (International) in the names of UPS models means that the models are designed for an input voltage of 230 V. The devices are equipped with sealed lead-free maintenance-free batteries with a service life of 3...5 years according to the Euro Bat standard. All models are equipped with limiting filters that suppress surges and high-frequency interference in the mains voltage. The devices emit appropriate sound signals when the input voltage is lost, the batteries are low, or there is an overload. The threshold value of the mains voltage, below which the UPS switches to battery operation, is set by switches on the rear panel of the device. Models BK400I and BK600I have an interface port that connects to a computer or server to automatically shut down the system, a test switch, and a buzzer switch.

The block diagram of the Back-UPS 250I, 400I and 600I is shown in Fig. 8. The mains voltage is supplied to the input multi-stage filter through a circuit breaker. The circuit breaker is designed as a circuit breaker on the rear panel of the UPS. In the event of a significant overload, it disconnects the device from the network, while the contact column of the switch is pushed upward. To turn on the UPS after an overload, it is necessary to return the contact column of the switch to its original position. The input filter-limiter of electromagnetic and radio frequency interference uses LC links and metal oxide varistors. During normal operation, contacts 3 and 5 of relay RY1 are closed, and the UPS transmits mains voltage to the load, filtering high-frequency interference. The charging current flows continuously as long as there is voltage in the network. If the input voltage drops below the set value or disappears altogether, or if it is very noisy, contacts 3 and 4 of the relay close, and the UPS switches to operation from the inverter, which converts the DC voltage of the batteries into AC. The switching time is about 5 ms, which is quite acceptable for modern switching power supplies for computers. The load signal shape is rectangular pulses of positive and negative polarity with a frequency of 50 Hz, a duration of 5 ms, an amplitude of 300 V, an effective voltage of 225 V. At idle, the duration of the pulses is reduced and the effective output voltage drops to 208 V. Unlike Smart models -UPS, Back-UPS does not have a microprocessor; comparators and logic chips are used to control the device.

The schematic diagram of the Back-UPS 250I, 400I and 600I UPS is almost completely shown in Fig. 9...11. The multi-link power supply noise suppression filter consists of varistors MOV2, MOV5, chokes L1 and L2, capacitors C38 and C40 (Fig. 9). Transformer T1 (Fig. 10) is an input voltage sensor. Its output voltage is used to charge batteries (D4...D8, IC1, R9...R11, C3 and VR1 are used in this circuit) and analyze the mains voltage.

If it disappears, then the circuit on elements IC2...IC4 and IC7 connects a powerful inverter powered by a battery. The ACFAIL command to turn on the inverter is generated by IC3 and IC4. A circuit consisting of comparator IC4 (pins 6, 7, 1) and electronic key IC6 (pins 10, 11, 12) allows the inverter to operate with a log signal. "1" arriving at pins 1 and 13 of IC2.

A divider consisting of resistors R55, R122, R1 23 and switch SW1 (pins 2, 7 and 3, 6), located on the rear side of the UPS, determines the mains voltage, below which the UPS switches to battery power. This voltage is factory set to 196 V. In areas where the mains voltage fluctuates frequently, resulting in frequent UPS transfers to battery power, the threshold voltage should be set to a lower level. Fine adjustment of the threshold voltage is performed by resistor VR2.

During battery operation, IC7 generates inverter excitation pulses PUSHPL1 and PUSHPL2. Power field-effect transistors Q4...Q6 and Q36 are installed in one arm of the inverter, and Q1...Q3 and Q37 in the other. The transistors are loaded with their collectors onto the output transformer. A pulse voltage with an effective value of 225 V and a frequency of 50 Hz is generated on the secondary winding of the output transformer, which is used to power the equipment connected to the UPS. The duration of the pulses is regulated by variable resistor VR3, and the frequency by resistor VR4 (Fig. 10). Turning the inverter on and off is synchronized with the mains voltage by a circuit on elements IC3 (pins 3...6), IC6 (pins 3...5, 6, 8, 9) and IC5 (pins 1...3 and 11... 13). Circuit based on elements SW1 (pins 1 and 8), IC5 (pins 4...V and 8...10), IC2 (pins 8...10), IC3 (pins 1 and 2), IC10 (pins 12 and 13), D30, D31, D18, Q9, BZ1 (Fig. 11) turns on an audible signal to warn the user of power problems. During battery operation, the UPS emits a single beep every 5 seconds to indicate the need to save user files because Battery capacity is limited. When operating on battery power, the UPS monitors its capacity and emits a continuous beep for a certain time before it is discharged. If pins 4 and 5 of switch SW1 are open, then this time is 2 minutes, if closed - 5 minutes. To turn off the sound signal, you need to close pins 1 and 8 of switch SW1.

All Back-UPS models, with the exception of the BK250I, have a bidirectional communication port for communication with a PC. Power Chute Plus software allows the computer to both monitor the UPS and securely automatically shut down the operating system (Novell, Netware, Windows NT, IBM OS/2, Lan Server, Scounix and UnixWare, Windows 95/98), preserving user files. In Fig. 11 this port is designated J14. Purpose of its pins: 1 - UPS SHUTDOWN. The UPS turns off if a log appears on this pin. "1" for 0.5 s.

2 - AC FAIL. When switching to battery power, the UPS generates a log on this pin. "1".

3 - CC AC FAIL. When switching to battery power, the UPS generates a log at this pin. "0". Open collector output.

4, 9 - DB-9 GROUND. Common wire for input/output signals. The output has a resistance of 20 Ohms relative to the common wire of the UPS.

5 - CC LOW BATTERY. In the event of a low battery, the UPS generates a log at this output. "0". Open collector output.

6 - OS AC FAIL When switching to battery power, the UPS generates a log on this pin. "1". Open collector output.

7, 8 - not connected.

Open collector outputs can be connected to TTL circuits. Their load capacity is up to 50 mA, 40 V. If you need to connect a relay to them, then the winding should be bypassed with a diode.

A regular “null modem” cable is not suitable for communication with this port; a corresponding RS-232 interface cable with a 9-pin connector is supplied with the software.

UPS CALIBRATION AND REPAIR

Setting the output voltage frequency

To set the frequency of the output voltage, connect an oscilloscope or frequency meter to the UPS output. Switch the UPS to battery mode. When measuring the frequency at the UPS output, adjust resistor VR4 to 50 ± 0.6 Hz.

Setting the output voltage value

Switch the UPS into battery mode without load. Connect a voltmeter to the UPS output to measure the effective voltage value. By adjusting resistor VR3, set the voltage at the UPS output to 208 ± 2 V.

Setting the threshold voltage

Set switches 2 and 3 located on the rear side of the UPS to the OFF position. Connect the UPS to a transformer type LATR with continuously adjustable output voltage. Set the voltage at the LATR output to 196 V. Turn resistor VR2 counterclockwise until it stops, then slowly turn resistor VR2 clockwise until the UPS switches to battery power.

Setting the charge voltage

Set the voltage at the UPS input to 230 V. Disconnect the red wire going to the positive terminal of the battery. Using a digital voltmeter, adjust the resistor VR1 to set the voltage on this wire to 13.76 ± 0.2 V relative to the common point of the circuit, then restore the connection to the battery.

Typical faults

Typical faults and methods for eliminating them are given in table. 4, and in table. 5 - analogues of the most frequently failing components.

Table 4. Typical Back-UPS 250I, 400I and 600I faults

| Defect manifestation | Possible reason | Method for finding and eliminating a defect |

|---|---|---|

| Smell of smoke, UPS does not work | Input filter faulty | Check the serviceability of components MOV2, MOV5, L1, L2, C38, C40, as well as the board conductors connecting them |

| The UPS does not turn on. The indicator does not light up | Input circuit breaker (circuit breaker) of the UPS is disabled | Reduce the load on the UPS by turning off part of the equipment, and then turn on the circuit breaker by pressing the circuit breaker contact column |

| Batteries are faulty | Replace batteries | |

| Batteries are not connected correctly | Check that the batteries are connected correctly | |

| Inverter faulty | Check the serviceability of the inverter. To do this, disconnect the UPS from the AC mains, disconnect the batteries and discharge capacitance C3 with a 100 Ohm resistor, test the drain-source channels of powerful field-effect transistors Q1...Q6, Q37, Q36 with an ohmmeter. If the resistance is several ohms or less, then replace the transistors. Check the resistors in the gates R1...R3, R6...R8, R147, R148. Check the serviceability of transistors Q30, Q31 and diodes D36...D38 and D41. Check fuses F1 and F2 | |

| Replace IC2 | ||

| When turned on, the UPS switches off the load | Transformer T1 is faulty | Check the serviceability of the windings of transformer T1. Check the tracks on the board connecting the T1 windings. Check fuse F3 |

| The UPS operates on batteries despite the fact that there is mains voltage | The power supply voltage is very low or distorted | Check the input voltage using an indicator or meter. If this is acceptable for the load, reduce the sensitivity of the UPS, i.e. change the response limit using switches located on the rear wall of the device |

| The UPS turns on, but no voltage is supplied to the load | Relay RY1 is faulty | Check the serviceability of relay RY1 and transistor Q10 (BUZ71). Check the serviceability of IC4 and IC3 and the supply voltage at their terminals |

| Check the tracks on the board connecting the relay contacts | ||

| The UPS hums and/or shuts down the load without providing the expected backup time | The inverter or one of its elements is faulty | See sub-item “Inverter faulty” |

| UPS does not provide expected power backup time | Batteries are discharged or have lost capacity | Charge the batteries. They require recharging after prolonged power outages. In addition, batteries age quickly when used frequently or in high temperature environments. If the batteries are approaching the end of their service life, it is advisable to replace them, even if the battery replacement alarm has not yet sounded. Check the capacity of the charged battery with a 12 V, 150 W car high beam lamp |

| UPS is overloaded | Reduce the number of consumers at the UPS output | |

| UPS does not turn on after replacing batteries | Incorrect connection of batteries when replacing them | Check that the batteries are connected correctly |

| When turned on, the UPS emits a loud tone, sometimes with a decreasing tone | Defective or severely discharged batteries | Charge the batteries for at least four hours. If the problem persists after recharging, the batteries should be replaced. |

| Batteries are not charging | Diode D8 is faulty | Check the serviceability of D8. Its reverse current should not exceed 10 μA |

| Charge voltage below required level | Calibrate battery charge voltage |

Table 5. Analogues for replacing faulty components

| Circuit designation | Faulty component | Possible replacement |

|---|---|---|

| IC1 | LM317T | LM117H, LM117K |

| IC2 | CD4001 | K561LE5 |

| IC3, IC10 | 74С14 | It is made up of two K561TL1 microcircuits, the conclusions of which are connected according to the pinout on the microcircuit |

| IC4 | LM339 | K1401SA1 |

| IC5 | CD4011 | K561LA7 |

| IC6 | CD4066 | K561KT3 |

| D4...D8, D47, D25...D28 | 1N4005 | 1N4006, 1N4007, BY126, BY127, BY133, BY134, 1N5618... 1N5622, 1N4937 |

| Q10 | BUZ71 | BUZ10, 2SK673, 2SK971, BUK442...BUK450, BUK543...BUK550 |

| Q22 | IRF743 | IRF742, MTP10N35, MTP10N40, 2SK554, 2SK555 |

| Q8, Q21, Q35, Q31, Q12, Q9, Q27, Q28, Q32, Q33 | PN2222 | 2N2222, BS540, BS541, BSW61...BSW 64, 2N4014 |

| Q11, Q29, Q25, Q26, Q24 | PN2907 | 2N2907, 2N4026...2N4029 |

| Q1...Q6, Q36, Q37 | IRFZ42 | BUZ11, BUZ12, PRFZ42 |

Gennady Yablonin

"Electronic equipment repair"

Modern UPSs are technologically and structurally complex, so their diagnostics and repairs must be carried out by service center professionals. We service UPS uninterruptible systems of all manufacturers and all models.

Thanks to the availability of specialized equipment, UPS repair carried out at the component level, which reduces its cost compared to modular replacement of elements.

All UPS repair work are made only in the service center hospital. If you wish, you can order a service from us - delivery of equipment to the hospital and back.

Diagnostics are free even if the customer refuses further repairs

Prices for repair of uninterruptible power supplies

Diagnostics in hospital

for free

Urgent diagnostics in a hospital (within 60 minutes)

Delivery of the product to the service center and back (within the Moscow Ring Road, + 35 rubles/km from the Moscow Ring Road)

Firmware recovery for uninterruptible power supplies (UPS/UPS) with power up to 750W

Replacing the battery of uninterruptible power supplies (UPS/UPS) with power up to 750W

Replacement of internal elements of uninterruptible power supplies (UPS/UPS) with power up to 750W

Preventive maintenance of uninterruptible power supplies (UPS/UPS) with power up to 750W

Repair of uninterruptible power supply board (UPS/UPS) with power up to 750W (Back-UPS) 1

Elimination of non-contacts of uninterruptible power supplies (UPS/UPS) with power up to 750W

Replacement of battery (UPS/UPS) with power up to 750W without disassembling the case

Firmware recovery for UPS with power from 750W to 3000W

Replacement of internal elements of UPS (UPS) with power from 750W to 3000W

Configuration, correction, calibration of UPS (UPS) with power from 750W to 3000W

Preventative maintenance of UPS (UPS) with power from 750W to 3000W

Repair of input/output connectors of UPS (UPS) with power from 750W to 3000W

Repair of UPS charger (UPS) with power from 750W to 3000W

Repair of UPS inverter board (UPS) with power from 750W to 3000W (simple repair)

Repair of UPS inverter board (UPS) with power from 750W to 3000W (high complexity repair)

Repair of UPS inverter board (UPS) with power from 750W to 3000W (moderate complexity repair)

Repair of UPS control board (UPS) with power from 750W to 3000W (simple repair)

Repair of UPS control board (UPS) with power from 750W to 3000W (high complexity repair)

Repair of UPS control board (UPS) with power from 750W to 3000W (moderate complexity repair)

Elimination of non-contact UPS (UPS) power from 750W to 3000W

Our company specializes in repair of uninterruptible power supplies any models from different manufacturers. Over the years, we have carefully studied the operating features of these devices and know the most common defects, as well as effective ways to eliminate them.

UPS (UPS) repair requires professional equipment, so we do not go to the customer’s site. We diagnose the problem at the service center absolutely free. You can also order a service from us for a minimal additional fee -. The courier will pick up your non-working device from your home, and after a short period of time will bring it back to the specified address in good condition.

UPS (UPS) repair requires professional equipment, so we do not go to the customer’s site. We diagnose the problem at the service center absolutely free. You can also order a service from us for a minimal additional fee -. The courier will pick up your non-working device from your home, and after a short period of time will bring it back to the specified address in good condition.

For each client a detailed acceptance certificate UPS in a hospital indicating the model and fault. Under this act, you will be able to receive the product after diagnosis or repair. We are confident in the quality of spare parts and the skills of our team, so we also order new parts if there was a need to replace old ones.

For each client a detailed acceptance certificate UPS in a hospital indicating the model and fault. Under this act, you will be able to receive the product after diagnosis or repair. We are confident in the quality of spare parts and the skills of our team, so we also order new parts if there was a need to replace old ones.  When ordering diagnostics and subsequent repairs from us, you will be able to receive current SMS notifications about the progress of work, seek advice on an issue that interests you. We will be happy to provide any information and answer all your questions. Phone numbers are indicated on the website and in the equipment acceptance certificate. The act also contains a QR code with a link to the page with online statistics for this order.

When ordering diagnostics and subsequent repairs from us, you will be able to receive current SMS notifications about the progress of work, seek advice on an issue that interests you. We will be happy to provide any information and answer all your questions. Phone numbers are indicated on the website and in the equipment acceptance certificate. The act also contains a QR code with a link to the page with online statistics for this order.  Pay for the order You can do it in a way convenient for you: in cash, by bank card, or by bank transfer. In our service, prices for repair work are optimally affordable in Moscow and meet quality standards. We use only original spare parts and certified equipment.

Pay for the order You can do it in a way convenient for you: in cash, by bank card, or by bank transfer. In our service, prices for repair work are optimally affordable in Moscow and meet quality standards. We use only original spare parts and certified equipment.

UPS Definition

UPS - uninterruptible power supply, which provides power when the main source is temporarily turned off, as well as protection from interference in the main source's electrical network. UPSs are specialized to provide constant power supply to desktop computers and electronic banking systems; security alarm systems, etc.

The main properties of the UPS:

- The UPS has 3 main operating modes - from the mains, from the built-in battery and a transition mode from the mains to the battery and back;

- the main characteristic of UPS performance is the time it takes to switch from mains to batteries and back;

- the form of the output alternating voltage of the device - the perfect form of the output voltage is a smooth sinusoid;

Main components of the UPS:

- network filter unit;

- control board and interface for computer;

- power electronics board.

Basic faults of an uninterruptible power supply

When you click the ON/OFF button, the indicator does not light up

The UPS beeps.

The cause of the malfunction may be damage to the network filter unit, a blown mains fuse, or an increase in the permissible load on the UPS.

The UPS beeps briefly

In this case, the uninterruptible power supply reliably handles voltage surges in the network, switching to backup mode.

Advice:

- check network parameters;

- set the highest input voltage range using microswitches No. 3 and No. 4 on the rear panel of the uninterruptible power supply;

- check the condition of the batteries.

The UPS produces an alarm sound

The "X" indicator lights up red

The probable cause of the damage may be a low battery, a blown fuse, increased load on the uninterruptible power supply, or failure of components on the power electronics board: diode bridge; key field effect transistors; control transistors and operation of thermal fuses.

Advice:

- check the voltage and capacity of the battery and, if necessary, charge them;

- check and, if necessary, replace the fuse with a new one;

- disconnect part of the load of the uninterruptible power supply, leaving fictitiously allowed;

- check the functionality of the specified electronic components and, if necessary, replace the damaged one.

When you click on the TEST button, the “X” indicator lights up in red

In this case, the +12 V battery is severely discharged.

Note: Fully charge the batteries or remove them from the uninterruptible power source and charge them from the charger.

The "~" indicator disappears and the battery indicator +/- lights up

This detection of damage indicates that the input supply voltage has disappeared and the transition to backup mode has not occurred due to a discharged battery or due to a damaged power electronics board.

Advice:

- charge the battery;

- check the functionality of the electronic elements of the inverter - key transistors, control transistors, diodes. If necessary, replace the inoperative part on the board.

Sources have long taken the place of a necessary component in modern computer systems and sets of other devices used both in enterprises and at home. Many consumers are familiar with the operating features and types of UPS. For them, a common one for a computer or, for example, specialized uninterruptible power supplies for boilers are not something new and unfamiliar. Especially on the territory of our country, where power grids, to say the least, are not characterized by the stability of the indicators given to end consumers. And the supply of electricity, it’s no secret to anyone, can be unexpectedly stopped, albeit for a short time, but at any moment.

Such a useful and necessary UPS

Before moving on to considering the possibilities of repairing a UPS with your own hands, which is what will be discussed below, we should once again note the importance of these devices. Uninterruptible power supplies are a kind of barrier between devices that consume electricity and the troubles that instability of the electrical power supplied to the equipment can bring. Developers are constantly improving their products and making them more versatile.

Thus, the UPS device allows you to organize, in most cases, fairly reliable protection not only for valuable user information in the case of a PC in the event of an unexpected shutdown of the lights, but also for the hardware components of other devices that are sensitive to voltage surges or its disappearance. But even a device designed to protect other devices from damage can sometimes fail itself. Let's look at the main components that make up an uninterruptible power supply, as well as relatively easy-to-fix UPS faults.

UPS device

At their core, sources are quite complex electronic devices consisting of many components. If you look at the diagram of a UPS, almost any one, you will find that the device consists of the following components:

- converters;

- switches;

- electrical energy storage devices (in most cases, a battery).

Why do breakdowns occur?

It is known that the more complex a system is, the greater the likelihood that it will fail due to the failure of one or more individual components. In general, the complexity of a UPS device is due to a fairly wide list of functions that the device must perform. This includes not only the ability to supply energy to electrical devices at the moment of voltage loss in the network, but also stabilizing and protective functions. There are devices that have even broader requirements. For example, uninterruptible power supplies for boilers must, in addition to the above, have the correct sine wave at their output. This complexity of the system makes it possible for some malfunctions to occur, although this does not happen often. What to do in this case? How to repair a UPS yourself?

Precautionary measures

Before proceeding with manipulations with the device, it should be borne in mind that the UPS is a complex electronic device and precautions must be taken when carrying out repair work. All operations with an uninterruptible power supply can be carried out only after making sure that the device is de-energized. No tips and secrets of UPS repair heard from friends or found on the Internet will save you from electric shock in case of rash actions and careless handling of live components!

Where to begin?

Of course, a UPS, like any other electronic device, requires the implementation of some basic rules during its operation. Very often, the cause of a malfunction that seems to the user is incorrectly connected wires, weakening or oxidation over time of their connection terminals, etc. Before thinking about carrying out serious repairs to the device, you must carefully inspect the connection of the wires, check their functionality, the absence of fractures and breaks in the cables, supplying the UPS, finally make sure that there is power in the outlet.

Performance support

In most cases, the device in question serves its owner for many years and without any problems. At the same time, to achieve this state of affairs, regular maintenance of the UPS is required, which consists of replacing the battery (approximately every two years) and general monitoring of the health of electronic components. If in order to control the properties of capacitors, resistors and other electronic elements you need quite deep knowledge in electronics and circuit design or a trip to a service center, then almost anyone can replace a UPS battery that has failed or lost its properties over time. Almost every device owner has to carry out such UPS repairs with his own hands at least once during the life cycle of the uninterruptible power supply.

Fuse

If the uninterruptible power supply does not turn on after a voltage drop or as a result of a short circuit in the supply network, it is likely that even disassembling it will not be necessary to restore the device’s functionality. The first thing you need to do when repairing a UPS yourself is to check the integrity of the fuse and replace it if necessary. Since this component fails quite often, UPS manufacturers design their devices in such a way that the user can carry out the procedure independently. Spare fuses themselves are often included in the delivery package of the uninterruptible power supply. If they are not there, a protective element similar to the one removed from the device can be purchased at any store that sells radio components. To replace the fuse, you need to find a special tray containing it on the case and remove/unscrew - depending on the design - the contents. After replacement, install the tray in its place. The procedure is described in more detail in the instructions for the UPS, but in general, any home handyman can figure it out without it.

Battery Replacement

To replace the battery you will need very little time and the only tool is a Phillips screwdriver. Initially, you need to unscrew several screws that fasten the parts of the case and are located at the bottom of the UPS, in special holes. This will allow you to remove the top cover and access the battery. In most cases, the battery is not secured in any special way inside the case and can be removed quite easily. You just need to disconnect the two wires that are connected to the battery using terminals. After removing the energy storage source from the UPS case, you need to determine its marking and purchase a similar battery from a specialized store. The UPS is assembled in the reverse order:

- Battery installation.

- Connecting wires, observing polarity.

- Installation and connection of parts of the device body.

Complex repair

If the above tips have been followed, that is, the UPS is connected correctly, the fuse in the device is intact and the battery is working, but the uninterruptible power supply still does not work properly, probably the most correct solution would be to contact a service center to repair the device. The fact is that the UPS circuit is quite complex for the average user; diagnosing and replacing, if necessary, individual electronic components without special tools and the skills of a craftsman at home is often simply not feasible. Thus, trying to repair a non-working device without certain knowledge and skills, as well as without the availability of appropriate equipment, a home repairman can only aggravate the situation.

In general, if you decide to repair a faulty UPS yourself, you must first weigh your strengths and capabilities. The average user is most often required to carry out simple manipulations, which would be more correctly classified as servicing the device rather than repairing it. It is better to entrust the elimination of complex breakdowns to professionals.

Our company has been servicing and repairing APC uninterruptible power supplies for more than five years. Timely servicing of the APC uninterruptible power supply can greatly extend its service life. If you want to save your nerves, time and money. In addition, untimely maintenance of the APC UPS can lead not only to malfunctions of the APC UPS itself, but also harm the health of personnel. That is why we recommend promptly servicing your APC UPS.

The scope and frequency of maintenance of the APC uninterruptible power supply is determined using the manufacturer's instructions and operating conditions. We strongly recommend servicing APC uninterruptible power supplies at least once a year.

It is important to remember that the service of the APC UPS at the stage of putting it into operation is that our engineer performs an external inspection of the UPS, diagnostics, and commissioning. Our engineer also monitors the self-diagnosis cycle of the APC UPS, configures the most appropriate operating parameters, and, if necessary, trains personnel.

Service maintenance of APC uninterruptible power supplies includes: visiting the customer, conducting diagnostic work using APC service software, visual inspection of the UPS, preventing contamination of the APC uninterruptible power supply, replacing thermal interfaces if necessary, visual inspection of the APC UPS for electrolyte leaks from the battery, swelling of the battery and oxidized contacts. In addition, the APC IBR service includes monitoring the condition of electrical wires and connections, monitoring the condition and performance of power elements of the APC uninterruptible power supply, monitoring the condition and performance of the cooling system, and monitoring the condition of APC batteries. The following is checked and, if necessary, adjusted: rectifier module, battery charging module, inverter module, internal settings and operating parameters of the APC UPS, and the performance of the self-diagnosis system. After this service work on the APC UPS, the values of the electrical parameters of the APC uninterruptible power supply are measured, and the internal measuring circuits are calibrated. After all the work on setting up and calibrating the operating parameters of the APC UPS, our specialist draws up a report on the condition of the UPS with recommendations for further operation.

The BSM Technologies LLC company is pleased to offer you its services for installation, post-warranty and routine maintenance of APC UPSs of various types and configurations, as well as repair services for APC uninterruptible power supplies. All work will be completed as quickly and efficiently as possible in accordance with the work regulations.

The service contract for servicing APC uninterruptible power supplies must include such important points as the frequency of work, the inclusion of spare parts in the cost of the contract, the inclusion of the cost of repair work in the cost of the contract, the response time of service engineers in the event of failure of the APC uninterruptible power supply, the need 24-hour telephone support from a service engineer, repair time if necessary.

Call us by phone and our manager will advise you on any issue related to the service and repair of APC uninterruptible power supplies.