Volumetric weight of a square pipe. Specific gravity of a shaped pipe, weight of a running meter of a shaped pipe

Profile pipes are used in various fields of human activity. Depending on their purpose, they can be made of various grades of steel, differ in size and sectional shape, and have different wall thicknesses. But all this variety has the same way of implementation, which lies in the fact that the price of the required piece depends on the weight running meter pipes. Next, we will analyze what this characteristic depends on and how to calculate the weight shaped pipe.

What determines the weight of profile pipes

The main parameter on which the weight of absolutely every product depends is the amount of material spent on its production.

Parameters reflected in the weight of the profile pipe:

- pipe shape;

- the thickness of its walls;

- the width of its walls;

- the density of the metal used for the production.

For example, there are two profile pipes, the size of which is the same, but one is made of steel and the other is made of aluminum. Their weight will be different, since they were used for their production different types metal.

Why you need to know the weight of profile pipes

There are two main reasons for calculating how much a meter of pipe weighs. One of them was named above - this is the determination of the price. Another reason is due to the conditions in which metal shaped pipes are used. As a rule, they are used in the construction of various objects. For example, for the installation of frames of building systems, in the furniture industry and for much more.

The engineer, having calculated the specific gravity of the profile pipe, will be able to establish the possible loads that it can withstand and the loads exerted by it on the structures located under it. Knowing the weight of the building materials used in the construction of structures allows you to perform high-quality design of buildings of various types.

Due to this, the probability of destruction of the structure will approach zero. Its physical and mechanical characteristics also depend on the weight of one meter of a profile pipe.

Taking into account the structural features of the facility being built, the engineer chooses the most suitable type of material. When calculating the required weight per meter of a profile pipe, it is imperative to take into account the operating conditions of the structure and its intended purpose.

The task set before the architect becomes more complicated if the object being built has a complex structure. Including the weight of the profile in the calculations, its various characteristics are determined, including the bending strength indicator.

The specialist must select such construction material, which will simultaneously solve two problems: it will be able to perfectly fulfill its intended purpose, and it will not be too expensive, so that the facility being built as a whole does not turn out to be excessively expensive. Making an accurate calculation of a profile pipe is not an easy task. To do this, you need to have special knowledge and some experience.

Like most building materials, profile pipes are assigned a strength class that indicates how much load they can be given. The higher it is, the correspondingly higher load bearing capacity.

Methods for calculating the weight of a profile pipe

Manufacturers produce square or rectangular... This building material has the best combination of price and strength. At the same time, the most popular are products with cross-sectional dimensions of 2 × 4, 4 × 4, 10 × 10 cm.

The weight of a profile with the same wall thickness and section dimensions is always different, in contrast to this standard parameter round pipe... Even the values \u200b\u200bgiven in the table of the weight of a running meter of a profile pipe given in GOST may differ from the real weight, since the weight of the finished product may be within acceptable limits.

How is the calculation of the weight of rectangular shaped pipes or any others, for example, to reflect a given parameter of a building material in technical documentation structures?

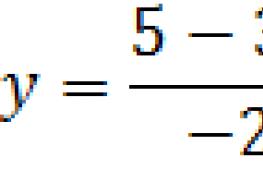

The formula for calculating the weight of a profile pipe is as follows:

M.P. \u003d S * 2 (A + B) * p

where S is the pipe wall thickness, indicated in meters;

A, B - the lengths of the sides of the pipe, indicated in meters;

p is the density of the material from which the pipe is made.

As a rule, the above formula is used in cases where it is not possible to refer to the tables, which contain all the necessary values. The tables will also help you find out how many meters of profile pipe in a ton.

Also, to find this parameter, in addition to the formula and tables, there are specially designed computer programs... They are able to calculate the weight of a profile of absolutely any shape.

Usually, to make calculations using the program, you must enter the following data into it:

- pipe shape;

- pipe length;

- pipe width;

- pipe height;

- wall thickness.

You will also be asked to select the type of material from which the building material is made. For example, steel, brass, copper and others.

Steel profile weight of the most demanded dimensions

Of the whole variety of types of steel profile pipes, only a few of them are used at home.

Below is the weight of profile pipes popular for self-construction:

- the weight of rectangular pipes with a cross-section of 2 × 4 cm with a wall thickness of 1.5 mm is 1.401 kg / m2, with a wall thickness of 2 mm - 1.853 kg / m3.

- the weight of pipes of square cross-section, the size of which is 2 × 2 cm, having a wall thickness of 1; 1.5; 2 mm equals 0.62; 0.93; 1.225 kg / m.p. respectively;

- the weight of square pipes with a cross-sectional size of 4 × 4 cm, if the wall thickness is 1; 1.5; 2 mm is 1.24; 1.849; 2.447 kg / m.p. respectively;

- the weight of a square pipe with a section of 10 × 10 cm with a wall thickness of 6 mm will be equal to 17.22 kg / m. Read also: "".

In order for the erected structure to be reliable, you need to correctly select the size of the section of the profile pipe, accurately make all the necessary calculations using one of the methods proposed above, and then carry out the installation in compliance with all the rules.

1. Theoretical weight according to GOST 8645-68 one 1 m / p - 4.42 kg

2. Deviations of the profile pipe wall can be identical to the width of the workpiece according to GOST 19903. Deviations in thickness do not apply to the profile bending points (corners)

3. Deviations in height, width of the profile pipe according to GOST 30245-2003 should be as a percentage: with a pipe height up to 100 mm +/- 1.0, not less than +/- 0.5 mm; over 100 mm +/- 0.8

4. In the cross-section of the profile, deviations from an angle of 90 degrees should not exceed +/- 1,30

5. The profile is made in length from 6.0 to 12.0 m; by agreement with the buyer, a profile pipe 60x40x3 can be made in length from 4.0 to 13.0 p / m

6. Twisting the other pipe should not fit within 2.0 mm plus 0.5 mm each 1 p / m profile according to GOST 30245

7. The ultimate tensile strength of the longitudinal weld should be not less than 0.95 ultimate tensile strength of the base metal

8. Reception and conditions for control of product acceptance, ave. Pipes 60x40x3 cm. GOST 30245-2003, paragraph No. 5

9. The guaranteed shelf life of the profile pipe is 24 months from the date of shipment by the manufacturer to the customer

10. The profile is marked according to GOST 7566, the marking must contain

- trademark enterprises, name.

- the dimensions of the pr. pipe.

- numbers of swimming trunks;

- profile length;

- the number of the profile;

- weight and numbers of packs;

- mark of quality control department.

Rectangular pipe 60x40x3 6m St3ps5

The cross-sectional area is 5.41 cm2, the moment of inertia of the section is 25.38 cm4, the plastic moment of resistance in the width is 6.72 cm3, the plastic moment of resistance in the height is 10.53 cm3, the moment of rotation in the width is 2.17 cm4, moment of rotation in height - 1.58 cm4. These indicators make it possible to calculate the maximum loads that a square pipe with dimensions of 60 × 40 × 3 mm can withstand. The mechanical strength values \u200b\u200bare indicated in accordance with the international standard EN 10219: 2006 for shaped rectangular metal cold-worked steel pipes.

They are used to create structural elements for universal purposes, they can be elements of complex mechanisms or production units. To improve performance, heat treatment can be carried out: hardening or tempering. The heat treatment parameters are chosen by the customer, changes and any deviations from the current standards are indicated in the contract and agreed by both parties. The values \u200b\u200bin the metal of sulfur and phosphorus are within the limits that do not significantly affect the characteristics of the material. The steel is semi-calm, which ensures its good weldability by electric welding under normal conditions without preliminary and subsequent treatment of the seam.

Steel tube products with a square or rectangular cross-section are called shaped tubes, or simply - "box". The profile types include types of rolled pipes, the cross-section of which differs from the square one - these are three-, six-, octagonal, ribbed, oval, drop-shaped and other shapes. Such a product is created on rolling mill by deformation of the steel sheet blank. Subsequently, the seam is welded.

Features of the production of profiled pipes

The "box-tube" can be made of various metals, but the most widely used is steel, whether carbon, alloy or stainless, or galvanized. There are also aluminum profile pipes.

The range of dimensions of rolled pipes is the largest, among them you can find samples with an outer diameter of 0.3 mm and up to 2520 mm, wall thickness varies from 0.05 mm to 75 mm. The most popular sizes are still rectangular shaped pipes in the range of 15x15 mm and up to 450x350 mm. The maximum wall thickness of such pipes is 12 mm.

Depending on the production method, there are:

- cold rolled,

- hot rolled,

- welded carbon profile pipes.

It should be noted that the price for deformed tubular products is higher, as is its quality. The main parameters of the profile pipe:

- geometry: weight of a running meter of a pipe, surface quality, conformity to norms of wall thickness and length, absence of maximum permissible deviations of evenness, thickness and other parameters;

- technical: production method, material quality, seam quality (regulated by GOST).

How to find out the weight of the pipe?

To find out how much a pipe weighs, you need to find out how much and what material went into its production. For calculations, it is enough to find out the weight of 1 m of a linear profile pipe. This applies to both large products, for example, 180x180x60, and small (50x50x5). The mass value depends on the following parameters:

- shape - the most popular products of rectangular cross-section, the scope of their application is very large (from construction to machine tool and automotive). Finding out the weight of a running meter of such a pipe is quite simple, without resorting to complex design programs;

- size - the data written in the product labeling are used to calculate the theoretical mass of the profile;

- Density (or specific gravity of the metal) - depending on the alloy, the characteristics of which are prescribed in the GOST, this indicator will differ. Steels of common grades have an average density in the range of 7.5 - 7.8 g / cm3.

The exact weight of the profile pipe must be known to carry out correct calculations of the mass of the structure, the weight that will put pressure on the support, determining the tonnage during transportation, the weight of the car, the cost of materials, etc.

At metal warehouses, they generally indicate the price per ton of the product, and no one weighs each pipe separately. But for calculations, a parameter is required - the weight of a running meter of a shaped pipe. You can use complex calculation methods or use a weight table steel pipe square of the most popular parameters:

| Profile pipe size (mm) | Wall thickness (mm) | The specific gravity of the profile pipe (kg / lm) |

| 15x15 | 1,0 | 0,48 |

| 15x15 | 1,5 | 0,71 |

| 15x15 | 2,0 | 0,93 |

| 20x20 | 1,0 | 0,62 |

| 20x20 | 1,5 | 0,93 |

| 20x20 | 2,0 | 1,23 |

| 25x25 | 1,0 | 0,79 |

| 25x25 | 1,5 | 1,18 |

| 25x25 | 2,0 | 1,55 |

| 30x30 | 1,0 | 0,94 |

| 30x30 | 1,5 | 1,40 |

| 30x30 | 2,0 | 2,30 |

| 40x40 | 1,0 | 1,24 |

| 40x40 | 1,5 | 1,85 |

| 40x40 | 2,0 | 2,45 |

| 50x50 | 1,5 | 2,34 |

| 50x50 | 2,0 | 3,10 |

| 50x50 | 2,5 | 3,86 |

| 60x60 | 1,5 | 2,80 |

| 60x60 | 2,0 | 3,72 |

| 60x60 | 2,5 | 4,63 |