Filtering gas masks are divided into the following types. Filtering or insulating? Which gas mask to choose? The most common types of domestic gas masks

The history of mankind knows many disasters and wars. One of the worst cases was the 1915 episode. Then the weapons of mass destruction were used for the first time - a weapon that strikes a large number of people in a short time. In 1915, the Germans sent a cloud of chlorine to the French army near Ypres. Thousands died then. Subsequently, weapons of mass destruction began to be used more and more often. This was the impetus for the creation of protective equipment. In particular, various types of gas masks and respirators were created. We will talk about them further.

Domestic personal protective equipment

Russia is not the initiator of the use of toxic substances. However, it was in our country that the gas mask was invented. Nikolay Zelinsky became its author. The scientist tested the device on himself. For several minutes Zelinsky stayed in a room filled with chlorine and phosgene (the most common poisonous substances at that time), and came out alive.

Subsequent inventions

Gas masks (types and purposes will be discussed later) during the First World War were not particularly diverse. They all became prototypes of Zelinsky's invention. The types of gas masks differed in the shape of the mask, name and country of origin. At the same time, absolute protection was provided only if the device was put on on time and the material was not damaged. The world was waiting for the next war. The states stayed in this state during the 20-30s of the XX century. In the Soviet Union, meanwhile, there were constant civil defense exercises. The purpose of the maneuvers was to train not only army soldiers, but also civilians, workers involved in industrial enterprises. It was then that filtering gas masks appeared. The purpose, types, composition, principle of operation of these devices were described in the instructions, explained during the exercises. These remedies were developed, one might say, for everyone. So, there were not only adults, but also children's gas masks. Protective products have been developed for horses. These animals acted as the main draft force and were used in the cavalry. Even for dogs, protective devices have been developed.

World War II

As part of the uniforms, the soldiers of all armies were, among other things, gas masks. Each soldier knew the types and purpose of these means of protection. However, during the Second World War, they were never needed. The Nazis were defeated without the use of poisonous compounds. The Germans themselves had sufficient quantities of OM. However, they did not use them, knowing that in the Soviet Union they would immediately respond in kind.

Cold war

After World War II, a new battle began. In the course of it, such toxins appeared, against which any kind of filtering gas masks were useless. Molecules of poisonous compounds, binary most often, became smaller and were not retained by activated carbon. The designers invented other, insulating, gas masks. The purpose, types, composition, principle of action of these funds differed from previous models. In fact, the new devices were an element of an underwater or space suit. It contains a source of oxygen. All types of insulating gas masks are distinguished by the absolute tightness of the inner space. These devices provide complete respiratory protection.

Types of gas masks and their use

All devices are used to protect the respiratory system, face skin, eyes from the negative effects of radioactive and toxic compounds, toxic vapors, bacterial aerosols, dust, smoke that may occur in industrial or other conditions. There are gas masks:

In addition, there are industrial and combat types of gas masks.

The simplest models

Filtering gas masks, as mentioned above, are equipped with a special box. Purification of the air entering the respiratory system is carried out in the process of adsorption, catalysis, chemisorption. In addition to the absorption box, the device has a front part. All items fit into the bag. The set includes anti-fog films or a special pencil for protecting glasses, as well as insulating cuffs for glasses. The connection of the box to the front part is carried out directly with an elastic tube or with its help. The charge is located in the cleaning element. It consists of activated carbon, which acts as a chemical absorber and catalyst, as well as a smoke filter. The face part includes a rubber mask (or helmet-mask) with goggles, a valve box with exhalation and inhalation compartments.

Samples used

Filtering gas masks for military purposes are represented by MO-2 models. Samples of GP-4u are used for the population. For children from 1.5 to 14 years old, DP-6m and DP-6 gas masks have been developed, up to 1.5 years old - special protective chambers. ShR helmets, presented in the form of a hood, were created for the victims who were burned and wounded in the head. In filtering gas masks industrial use used boxes of brands BKF, KD, B, A and others. They absorb vapors and aerosols of specific toxic substances. The latter, in particular, include hydrogen derivatives of sulfur, arsenic, phosphorus, nitrogen, carbon monoxide, acid gases, and so on. Dust protection is provided by respirators P1B-1, F-57, PRB-5, RPP-57 and others.

Features of use

The filtering gas mask has a negative effect on the body. It is conditioned by:

- Resistance to breathing that increases during work.

- Limitation of the field of view.

- The presence of space in the facial area, filled with part of the exhaled air enriched with CO2.

- The pressure of the mask on the fabric.

- Difficulty in sound perception and speech transmission.

Filtering gas masks reduce performance, but do not interfere with the continuation of production or combat activities. To improve endurance, you need to train regularly. At low temperatures and winds, protection must be provided against possible frostbite under the mask in the neck and chin area.

Isolating gas masks

These devices are used in the presence of toxic compounds in the air in high concentrations. Also, these types of gas masks provide protection against substances in which the devices discussed above are powerless, as well as in the case of insufficient oxygen in the atmosphere and in underwater work. There are 2 types of these devices. They differ in the way they deliver oxygen for breathing. In models of the first type, it is supplied from a balloon in which it is compressed. In other types of gas masks, the supply is carried out from peroxide compounds, in which oxygen is in a chemically bound form. The duration of work in these protective equipment will depend on the intensity of the load and can reach several hours. In mine rescue operations and industrial conditions, such types of gas masks are used as:

Features of operation

In an insulating gas mask, a gas mixture enters the respiratory system, in which the content of CO 2 and O 2 is increased, as well as the level of humidity and temperature. The front of the device also has a negative effect. Isolating gas masks are complex, bulky and heavy. As a result, work in them is much more difficult. To prevent accidents, it is necessary to strictly follow the rules for using protective equipment and provide medical supervision.

Potential threats

When selling personal respiratory protection equipment, sellers and manufacturers must indicate the scope of acceptable use of the product. However, neither the USSR, nor then the Russian Federation established any restrictions. In this regard, in order to increase turnover and attract maximum profit for advertising purposes, some manufacturers and sellers unreasonably significantly overestimate the effectiveness of their products. Thus, consumers have a misconception about the safe use of gas masks. Selection of insufficiently effective adaptations occurs in cases where OT training programs do not include these issues. In many of the gas masks that were produced during World War II, the filter frames were made of cellulose fibers containing asbestos. This material has a dense structure. However, in spite of this, if the filter is damaged, the concentration of the components of the material may increase.

Instructions for use

1. Traveling position. The gas mask is in the bag at the waist level on the left side. All buttons must be buttoned up.

2. Standing at the ready. In case of a threat of infection, at the "Attention" command, move the bag to the abdomen and unfasten the buttons.

3. Combat position. At the command of "Gaza" it is necessary to put on a gas mask. This is done as follows:

- When you receive a command, you should hold your breath without inhaling air.

- Close eyes.

- Holding the bag from below with your right hand, take out a gas mask with your left.

- Remove the plug from the box.

- The thumbs are located outside the face, the rest are inside.

- The lower part of the mask is applied to the chin.

- The gas mask is pulled up sharply.

- Exhale.

- Open eyes.

- Check the mask for wrinkles - glasses should be at eye level.

Removal of the device is as follows:

Finally

Development of funds for individual protection was stimulated not only by military threats. The 20th century has also become a period of large-scale man-made disasters. The development of qualitatively new methods of ensuring protection was due to the rapid development of radioactive production, the chemical industry, and the launch of nuclear reactors. As a result, types of gas masks began to appear that cannot be used in battles. However, they effectively provide protection for employees of enterprises involved in harmful production. In some cases, in accordance with the nature of the contamination, you can use simpler respiratory devices. They can provide protection against inhalation of dust. In fact, respirators are a simple analogue of gas masks. For military purposes, more expensive and complex designs are used, the production of which is economically unprofitable for the civilian population.

A gas mask is a means of personal protection of the respiratory system from harmful substances in the atmosphere. In simple terms, a gas mask is a device that allows you to protect the human body from poisoning with toxic impurities while in a dangerous area.

Gas masks: varieties and design features

Gas masks have several depending on many factors. The two largest groups into which all gas masks can be divided according to their method of protection are filtering type and insulating gas masks.

A gas mask of any kind includes a front part and components responsible for cleaning or supplying purified air to the respiratory system.

The front part of the gas mask is made in the form of a full-face sealed mask (or helmet) of green or black rubber, and in some modifications of durable thermoplastic. One of the main distinctive elements of the front part is the viewing glasses (spectacle assemblies). Gas masks, depending on, can have a mask with a standard arrangement of glasses, with a frontal one, with an increased viewing angle, or a mask with a panoramic glass. In addition to the spectacle unit, the front part of the gas mask includes inhalation / exhalation valves, and some models can be equipped with an intercom, a device for receiving liquids.

Filter-type gas masks are equipped with replaceable ones, which are responsible for screening out dangerous particles in the contaminated air and preventing them from entering the body. Since there can be a lot of toxic substances in the atmosphere, and they all differ in both their composition and concentration, the filters used in gas masks are also always different. A filtering-absorbing box is responsible for cleaning the air from impurities, which consists of an anti-aerosol filter (which retains dust and aerosols on its fibers) and a charge of active carbon (absorbing harmful vapors and gases). Gas masks of this group work only on the principle of filtering polluted air and are not capable of producing pure oxygen, therefore their use is impossible if there is less than 17% pure oxygen in the polluted atmosphere.

Insulating gas masks, instead of a filter element, have a regeneration and air purification system: a regenerative cartridge, a breathing bag, an oxygen cylinder. The device of such gas masks also depends on their purpose and modification. Apparatus of this kind completely isolate the respiratory organs from the environment. The gas mask begins its work after activating the trigger of the regenerative cartridge, which releases the first portions of oxygen. The principle of operation of insulating gas masks in total boils down to the following: the exhaled air enters the regenerative cartridge, in which it is purified from carbon dioxide and enriched with oxygen. The breathing bag serves as a container for purified air, from which it then enters the respiratory system through the inhalation valve. Since these gas masks completely exclude any interaction with a polluted atmosphere, they can be used with any composition and concentration of harmful substances.

There is another type of isolating apparatus - hose-type gas masks. A distinctive feature of such gas masks is the method of supplying clean air to the body, carried out through special hoses from a clean atmosphere. The operation of hose devices is limited by the length of the hoses themselves, which can be 10, 20 or 40 m. Gas masks of this type are widely used when working in wells, tanks and other confined spaces.

Filtering and insulating gas masks can have the same purpose, that is, the ability to protect the body from the same harmful substances in the same conditions. Here it is worth paying attention to the peculiarities of using each type of apparatus. Filtering masks are easier to use, have less weight and, accordingly, exert less pressure on the face. The operating time in such gas masks depends on the operating time of the filter, which, after working out, can simply be replaced with a new one and continue working. However, filter-type gas masks can be used only if the composition and concentration of harmful impurities is accurately known, as well as if there is a fraction of pure oxygen in the atmosphere necessary for a person. Isolation devices can be used in any cases - when working with an unknown composition of toxic substances, with a lack or complete absence of oxygen. But, despite such a universal protection, still more often preference is given to filtering gas masks, since isolation devices have a very complex structure and an untrained person will rarely be able to use them correctly. The duration of the insulating gas mask is limited by the supply of an oxygen cylinder, refueling of which cannot be compared in time with changing a used filter. By virtue of their design, isolation devices are much heavier, which makes their long-term use difficult.

Gas masks and their scope

If we talk about the field of application of gas masks, then we can distinguish gas masks,.

Civilian gas masks are intended for use by the general population when evacuating from a contaminated area, or for carrying out the necessary work in a contaminated environment. Gas masks of this type are widely used in accidents associated with bacteriological, chemical, radioactive air contamination. Civilian gas masks belong to filtering devices, usually they have the simplest modifications, which ensure easy donning and use.

Gas masks for industrial use are designed for use in industries of a specific orientation in cases of accidents or unforeseen situations. Such gas masks are equipped with enterprises whose activities are related to the use or storage of a certain type of hazardous substances. Due to the fact that potentially dangerous contaminating substances are known in advance, these gas masks have a narrow focus, but thereby a higher degree of protection.

Military gas masks are used during training exercises or fighting. Such devices have a more complex design and are usually equipped with both intercom devices and devices for receiving liquids. Gas masks for military use can be either filtering or insulating and are suitable for use on any type of contaminated facility.

What the gas mask protects and does not protect from

One of the most popular questions of people who have not had to deal with gas masks is whether there is a gas mask that protects against everything. Filter-type gas masks have a specific focus on protection against a specific type of substance, which is determined by the filters used. If a gas mask is used at an enterprise working with certain hazardous substances, then the employer, in case of accidents or unforeseen situations, purchases gas masks that protect against these substances. For the civilian population, gas masks with a standard set of filters are provided, the action of which is aimed at protecting against many harmful emissions - aerosols, dust, vapors and gases. However, an additional filter must be purchased to protect against carbon monoxide. And do not forget that the use of filtering gas masks is possible only if the necessary proportion of oxygen in the contaminated environment is available.

Insulating gas masks protect against all types of substances and at any concentration, including such masks can be used in the complete absence of oxygen. However, due to their complex design, such gas masks require preliminary training before using them, so the untrained civilian population simply cannot cope with them. In addition, any gas mask exerts pressure on the face, on the head, noticeably complicates breathing, and in devices of the insulating type, due to their greater mass, these properties are increased.

As a result, we can conclude that with a properly selected gas mask for its purpose and competent use of the apparatus, it reliably protects the body from poisoning with harmful substances as part of its protective effect. But if the filter is not designed to protect against certain substances, or with a suitable filter, the gas mask is not used correctly, for example, poisoned air enters the mask space, bypassing the inhalation valves, due to a violation of the tightness of the mask or a malfunction of its other parts, then use the gas mask becomes completely useless.

Gas masks: how to put on, apply, check

In order for a gas mask to meet its purpose, it is necessary to use it correctly, including putting it on, storing it and checking its integrity and performance in a timely manner.

A gas mask is put on with closed eyes and with held breath. First of all, the lower part of the mask is applied to the chin, leaving only thumbs, and then with a sharp movement is put on the whole head. The mask should not form any folds, but, on the contrary, should fit snugly to the face, maintaining complete tightness.

It is important to check the gas mask both before using it and during storage. Devices with mechanical damage, missing or malfunctioning of any components, as well as gas masks not of their size, are not allowed for use. Using a visual inspection before using the gas mask directly, you must make sure that there are no chips and cracks on the glass, holes, tears or scratches on the mask, rust or corrosion on metal parts, including the filter box. If any kind of damage is found, this part must be replaced.

When using filter-type gas masks, it is always necessary to monitor the filter life and replace it in a timely manner. In the case of isolating devices, it is not allowed to use them with a spent regenerative cartridge, as well as to replace it while in the contaminated area. It is recommended to store and carry gas masks in a specially designed bag.

Popular models of gas masks

Gas masks GP

Gas masks for the civilian population GP7 are among the most popular models and are designed to protect against aerosols, vapors and gases of military toxic chemicals, from radioactive substances, biological aerosols, emergency chemically hazardous substances, including ammonia and organic compounds with a boiling point below 65 ° C.

A mask of this kind of gas masks can have both a spectacle unit with an increased viewing angle and a panoramic glass. Additionally, the models can be equipped with a device for receiving liquid.

Children's gas masks

Children's gas masks are also civilian, and can have modifications for school children up to 16 years old and for preschoolers from 1.5 years old. The difference between a children's gas mask is the size of the front part.

Gas masks PPM and ShMP

ShMP gas masks have a helmet-mask made of durable rubber with a standard goggle assembly and differ in the characteristics of the filters used, depending on which they can protect against smoke, aerosols, vapors and gases of organic and inorganic substances, etc. ShMP gas masks filters and can have 1.2 and 3 class of protection.

PPM gas masks also, depending on the filters used, have various protection against various kinds of hazardous substances. The PPM gas mask is equipped with a panoramic glass, a mask in three sizes, inhalation and exhalation valves, an intercom and an adjustable elastic headband and can be used with any filter.

Gas masks PSh

Hose gas masks are very widely used in places with a minimum area of \u200b\u200bcontamination, protecting the body from toxic substances by isolating the respiratory system from the harmful environment. These masks can be used in confined spaces with insufficient or no oxygen.

Gas masks of this type have a very wide range of models, the differences in models of which are the length of the hose (10, 20, 40 m), the type of face part (helmet-mask or panoramic mask), the presence or absence of a hose reel, the type of air supply (natural , hand or blower), etc.

Gas mask IP

The IP gas mask is an insulating type gas mask, the basis of which is the action of a regenerative cartridge. The air exhaled by a person enters the regenerative cartridge, the substance of the cartridge absorbs the carbon dioxide and moisture contained in it, and instead releases the oxygen necessary for breathing. The oxygen-enriched breathing mixture enters the breathing bag. When inhaling, the mixture from the breathing bag repeats this cycle again.

Starting from school, everyone knows what a gas mask is and how to use it, because this is taught in the lessons of life safety and initial military training. And this is no coincidence. Back in 1915, as a result of hostilities, one of the opponents used chemical weapons, including poisonous chlorine vapors,

from which a lot of soldiers and civilians died. And since then, any war, unfortunately, is filled with chemical weapons and poisonous enemy attacks. But a person is built in such a way that he can find opposition to any action. That is why a gas mask was invented to avoid poisoning.

Today in our world there are dozens, if not hundreds, of models of gas masks, differing in the principle of performance and their purpose. Let's look at the separation properties of gas masks in order to understand what are their main differences from each other.

Classification of gas masks according to the principle of belonging

Before proceeding closely to the classification of gas masks, it is worth remembering what they are for. Gas masks are used to protect the respiratory tract from the penetration of poisonous impurities and other chemically hazardous substances. Therefore, the primary division of gas masks will be as follows:

As a rule, civilian gas masks are placed in crowded places so that in the event of a chemical attack by an enemy, people can escape from the poisonous and contaminated air. They include the simplest elements, without bothering a person in research and the ability to use any complex details of PPE.

As for military gas masks, they are equipped with specialized attributes, such as a hose for sucking air and its ultra-high-quality processing, etc., because soldiers, sensing danger, should not flee from the battlefield, but, on the contrary, go to the very firing point of the attack with a goal attacks on the enemy.

Industrial gas masks are made using a special technology. They contain a large volume of substances that carry out multiple processing of toxic air, since man-made disasters entail chemical explosions, the release of carbon monoxide and many other dangers lasting more than one day.

Classification of gas masks by the method of protection

Having clarified the situation with the classical classification of gas masks, let's move on to a more complex differentiation.

By functionality, gas masks are divided into:

- - filtering gas masks;

- - insulating gas masks.

Filtering gas masks work on the principle of sucking in contaminated air, processing it through a filtering absorbing box and releasing carbon dioxide through special protected openings after a person inhales. Such gas masks are very popular, due to its long-term use, in emergency situations you can stay in a filtering gas mask for up to 12 hours.

Other, less popular, but also useful PPE include self-contained gas masks, based on the breathing of a person inside a gas mask with pre-prepared clean air. They contain a large reservoir of air, which is somewhat reminiscent of a scuba diver's oxygen cylinder. The disadvantage of such a gas mask is that its direct operation should not exceed 3 hours, and of course, walking with such a gas mask is also quite difficult, because when fully loaded, it weighs more than one kilogram.

Classification of gas masks by built-in parts

Modern gas masks are equipped with parts that a person needs for normal life in conditions emergencies... Therefore, some gas masks are divided into:

Modern gas masks are equipped with parts that a person needs for normal life in conditions emergencies... Therefore, some gas masks are divided into:

- - gas masks with a device for receiving water;

- - gas masks without a device for receiving water.

According to the certification of PPE, gas masks with a device for receiving water are designated as GP-7 B, and gas masks without a device for receiving water - GP-7 BV, where the GP can be replaced with any other types of PPE.

Classification of gas masks by air supply options

Before talking about the classification of gas masks by the method of air supply, it is worth mentioning that PPE comes with and without a hose. The gas mask hose performs the function of supplying air, which is precisely the difference. Hose gas masks are differentiated into:

- - self-priming air gas masks;

- - gas masks with forced supply of clean air.

Gas masks that work on the principle of self-priming clean air are based on the mechanical effect of a person. By taking deep breaths, clean air through a hose enters the respiratory tract of a person, carbon dioxide is exhaled through a special valve.

PPE with forced supply of clean air is equipped with auxiliary attributes, such as a compressor line, blowers or some kind of fan, due to which high-quality treatment of contaminated air is carried out. Such a gas mask also causes a lot of trouble in its operation, because its weight reaches 16 kg, which is very difficult for an unprepared person, and besides, running with such equipment will not work at all, therefore a person using a gas mask with forced air supply dooms himself to immobility and waiting outside help.

Gas mask filter classification

In addition to the functional differences between gas masks, there is a classification of filters by classes:

- - Class 1, gas masks equipped with such a filter have low filtration, and can save a person only from fine dust that does not have harmful toxic substances.

- - Class 2, such gas masks are suitable for domestic use, in which the maximum that a person can face is harmful toxins, corrosive smoke and substances formed during the combustion of oil products.

- - Class 3, these are the most effective gas masks, which are perfect for protection against toxic substances, as a result of enemy chemical attacks or any man-made accident.

It is usually possible to replace the filter element.

· insulating - Generation of a breathing mixture, that is, the respiratory organs do not breathe with the surrounding air, but with the air generated by the regenerative cartridge and the oxygen enrichment system.

· hose - delivery of air mixture from a certain distance (10-40 meters), usually used when working in containers.

First in Russian Empire hose gas masks were used in the gilding of the domes of St. Isaac's Cathedral in St. Petersburg, in 1838-1841. They were glass caps with a hose through which air was supplied, but they were not saved from poisoning, 60 craftsmen died. Apparently there was no skin protection through which high concentration mercury vapors could be absorbed. The world's first filtering coal gas mask, invented in the Russian Empire by the Russian scientist Nikolai Dmitrievich Zelinsky in 1915, was adopted by the Entente army in 1916. The main absorbing material in it was activated carbon. See Sketch of the development of the Russian gas mask 1914-1918,

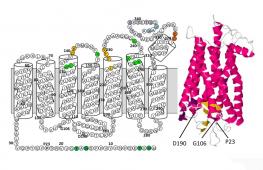

Gas mask structure

Rubber helmet-mask

Filter box

Spectacle knot

Fairings

Respirator

Valve box (one valve for inhalation, two valves for exhalation (but not always))

Connecting tube (not on all models)

Some gas masks contain an intercom membrane

Some gas masks are equipped with drinking devices (through a rubber tube)

Some gas masks are equipped with a device that allows you to wipe the glass from the side of the face

Using a gas mask

The gas mask is used as an independent personal protective equipment, and in a set with other means (for example, L-1, OZK, and (OKZK)

The gas mask is worn in the following positions:

Regulation No. 1 - Marching: The gas mask is located in the bag on the left side and at the waist level. All buttons are buttoned.

Regulation No. 2 - Ready: If there is a threat of infection. At the command "Attention!" it is necessary to move the gas mask bag on the stomach and unfasten the buttons.

Regulation No. 3 - Combat: On command: "Gases!" put on a gas mask.

How to put on a gas mask:

1. At the command "Gaza!" hold your breath without inhaling air.

2. Close your eyes.

3. Get the gas mask out of the gas mask bag, taking out the gas mask with your left hand, and holding the bag from below with your right hand.

4. Pull the valve out of the filter.

5. Before putting on the gas mask, place the thumbs outside and the rest inside.

6. Place the lower part of the helmet-mask on the chin.

7. Sharply pull the gas mask over your head from the bottom up.

8. Exhale.

9. It is necessary that after the formation of folds, the spectacle knot should be located at eye level.

10. Move the bag to its side.

Withdrawal:

1. On the command "Hang up!" take with index fingers under the ears and pull it upwards.

2. Put the gas mask in the gas mask bag.

3. Fasten the buttons

Labeling and purpose of filters in gas installations

Efficiency classes

Note 1 to classes: filters for special gases and type AX are not marked with a class, they may be marked with additional conditions. For example, an anti-CO filter is denoted as CO-number, where the number is the limiting weight in grams, after which the filter is changed.

Note 2 to Classes: For aerosols, the classes are as follows:

1 - Coarse dust,

2 - Dust, smoke, fog,

3 - Fine mist, suspended matter, smoke, bacteria, viruses.

Note 3 to classes: Classes are written immediately after the designation of hazardous substances.

The list and purpose of various brands of filtering elements for gas mask RPE, adopted in our country in accordance with the new standard, harmonized with EU standards. They differ in color and lettering.

| Filter element brand | Distinctive coloration | Harmful substances from which protection is provided |

|---|---|---|

| Aerosols (dust, smoke, fog), bacteria and viruses |

||

| Brown | Organic vapors and gases with a boiling point\u003e 65 ° C |

|

| Inorganic gases (chlorine, fluorine, bromine, hydrogen sulfide, carbon disulfide, cyanogen chloride, halogens), except CO |

||

| Acid gases and vapors of nitric acid |

||

| Ammonia and amines |

||

| Nitrogen oxides |

||

| Organic mercury compounds, mercury vapor |

||

| Brown | Boiling point organic vapors< 65°С |

|

| Purple | From special substances (sarin, soman, phosgene and others) |

|

| Orange | Radioactive iodine, radioactive methyl iodide and radioactive particles |

|

| Purple | Carbon monoxide (CO), the numbers indicate the maximum allowable increase in filter mass |

Note on symbols:

Filters can protect both from one type of harmful substances, and from several, in almost any combination.

Example 1: A2B2E1K1P3 - protects against organic gases and vapors with a boiling point of more than 65 degrees, at a concentration of up to 0.5% vol., Inorganic gases, except for carbon monoxide at a concentration of up to 0.5% vol., Acid fumes at a concentration of up to 0, 1% vol., Ammonia and amines at a concentration of up to 0.1% vol., As well as from fine aerosols, bacteria and viruses. Has the following colors: brown, gray, yellow, green and white

Example 2: A2B3E2 - protects against organic gases and vapors with a boiling point of more than 65 degrees, at a concentration of up to 0.5% vol., Inorganic gases, except carbon monoxide at a concentration of up to 1% vol., Acid vapors at a concentration of up to 0.5% about. It has the following colors: brown, gray, yellow.

| Substance | Filter brand | Notes (see end of table) |

|---|---|---|

| 1, 2 dichloroethane | ||

| 2-nitropropane | ||

| 2-propanol | ||

| adipic acid | ||

| nitric acid | ||

| acrylamide | ||

| acrylic acid | ||

| acrylonitrile | ||

| acrolein | ||

| aliphatic naphtha | ||

| allylamine | ||

| allyl alcohol | ||

| amyl acetate | ||

| aromatic naphtha | ||

| acetaldehyde | ||

| acetamide | ||

| acetyl chloride | ||

| banzaldehyde | ||

| benzyl chloride | ||

| benzotriazole | ||

| beryllium | ||

| butyl acetate | ||

| butyraldehyde | ||

| vinyl acetate | ||

| vinyltoluene | ||

| hydrazine | ||

| antimony hydride | ||

| potassium hydroxide | ||

| sodium hydroxide | ||

| hydroquinone | ||

| sodium hypochlorite | ||

| gluturaldehyde | ||

| diacetone alcohol | ||

| diglycidyl ether | ||

| dimethyl sulfate | ||

| dimethylformamide | ||

| silica | ||

| sulfur dioxide | ||

| chlorine dioxide | ||

| chlorine dioxide | ||

| carbon disulfide | ||

| isopropyl alcohol | ||

| isophorone | ||

| sodium carbonate | ||

| cobalt (dust and smoke) | ||

| antifouling paint | ||

| fluorosilicic acid | ||

| maleic anhydride | ||

| manganese | ||

| methyl acrylate | ||

| methylamine | ||

| methyl bromide | ||

| methylene diphenyl isocyanate | ||

| methyl isobutyl ketone | ||

| methyl iodide | ||

| methyl methacrylate | ||

| methyl alcohol | ||

| methyl chloride | ||

| methyl chloroform | ||

| methyl ethyl ketone | ||

| monomethylamine | ||

| glycol monomethyl ether | ||

| morpholine | ||

| formic acid | ||

| arsenic (not arsine) | ||

| nickel metal | ||

| silver nitrate | ||

| nitrobenzene | ||

| nitroglycol | ||

| nitroglycerine | ||

| aluminium oxide | ||

| vanadium oxide (dust) | ||

| iron oxide (smoke) | ||

| calcium oxide | ||

| zinc oxide (smoke) | ||

| ethylene oxide | ||

| organic peroxides | ||

| pentachlorophenol | ||

| sodium perborate | ||

| potassium permanganate | ||

| perchlorethylene | ||

| piperazine | ||

| piperidine | ||

| hydrofluoric acid | ||

| polychlorinated biphenyl | ||

| propionic acid | ||

| dust inert | ||

| mercury (vapor) | ||

| p-phenylenediamine | ||

| lead (dust and smoke) | ||

| hydrogen selenide | ||

| sulfuric acid (fog) | ||

| hydrogen sulfide | ||

| sodium silicate | ||

| hydrocyanic acid | ||

| hydrochloric acid | ||

| sulfamic acid | ||

| selenium sulfide | ||

| turpentine oil | ||

| tetrahydrofuran | ||

| tetramethyl lead | ||

| tetrachlorethylene | ||

| tetraethyl lead | ||

| tributyl phosphate | ||

| tridymite (silicon dioxide) | ||

| trimethylbenzene | ||

| trisodium phosphate | ||

| trichloroethane | ||

| trichlorethylene | ||

| white Spirit | ||

| acetic acid | ||

| acetic anhydride | ||

| formaldehyde | ||

| phosphoric acid (fog) | ||

| phthalic anhydride | ||

| sodium fluoride | ||

| furfural | ||

| cotton dust | ||

| aluminum chloride | ||

| benzoyl chloride | ||

| ferric chloride | ||

| methylene chloride | ||

| zinc chloride (smoke) | ||

| allyl chloride | ||

| vinyl chloride | ||

| vinylidene chloride | ||

| perchloric acid | ||

| chloroprene | ||

| chromic acid | ||

| cyanide (in CN form) | ||

| cyclohexane | ||

| cyclohexanol | ||

| carbon tetrachloride | ||

| oxalic acid | ||

| epichlorohydrin | ||

| ethyl acrylate | ||

| ethyl acetate | ||

| ethyl bromide | ||

| ethylene glycol | ||

| ethylenediamine | ||

| ethylenediamine tetraacetate | ||

| ethyl ether | ||

| ethyl chloride |

Note:

1. It is necessary to use combined filters

2. The maximum use time of combined filters for protection against mercury vapor is 50 hours

3. Use a full face mask

4. Oncogenic

5. Absorbs into the skin

6. Considered a sensitizer (a substance introduced into the phyto-layer).

Particle shapes:

Radioactive particles appear as a result of radiation

Dust consists of organic and inorganic solids in the air (minerals, metals, coal, wood, fiber, etc.)

Gas masks are means to protect the respiratory system, eyes and skin from hazardous substances in the air. We invite you to familiarize yourself with the different types and types of gas masks.

You will learn about the design features of protective equipment, how to choose a gas mask, how to wear it correctly and what is prohibited when wearing it. Read the most complete instructions for civilian gas masks.

What is a gas mask and what is it for

Gas masks are divided into different types and types, they depend on the design features and their area of \u200b\u200bapplication. Next, we will consider which models of gas masks are used in specific situations. The purpose of gas masks is different:

- Protection of civilians located in a radius of contamination with potent toxic substances (SDYAV) for safe movement.

- Protection during the military use of bacteriological, chemical weapons (performance of combat missions in contaminated conditions).

- Protection of personnel of industrial enterprises interacting with SDYAV at work.

- Immersion in water (with an insulating gas mask).

- Work in smoky rooms (rescue services, firefighters).

- Carrying out work and rescue operations in rooms with sprayed aerosols.

- Working with aerosol substances in everyday life (when spraying garden plots).

Types of gas masks

In terms of the internal structure and method of protection, there are two main types: filtering gas masks and insulating.

Civilian filtering gas masks (GP) are equipped with a filter box, which allows air purification when inhaled. A person inhales the same air that is around him, but without harmful impurities.

The filters are suitable for specific types of toxic substances and are easy to replace.

An insulating gas mask (IP) is equipped with a compressor box and is used when there is a lack of oxygen in the environment. The main difference from GP: a person inhales air from a protected source and is completely isolated from the effects of SDYAV.

This method of protection is universal, its effectiveness is not related to the type of air pollution.

IP are subdivided into autonomous (they have their own compressed air cylinder) and hose-type (air enters them from an external source using a long hose).

The purpose of the insulating gas mask:

- When there is a large amount of hazardous substances in the air.

- When the air is saturated with substances that can pass through the GP filters.

- Oxygen-free and for underwater work.

Types of gas masks by scope

Gas masks are used in different spheres of life, they are divided into several groups:

- Civil (GP).

- Military mask-box (PMK).

- Industrial (VK).

- Baby and infant.

Civilian gas masks are used to preserve the health of people during a chemical attack and air pollution. They have the simplest design and device that every person can understand. You can use them after minimal instruction.

Military gas masks have a more complex device and are supplemented with various attributes (hose, different filters, an air cylinder, and so on). Even during the use of secondary battery, the soldier must be able to perform combat missions.

Industrial devices are used in hazardous industries where the concentration of SDYAV is exceeded and when there is a threat of emergency situations... Baby and infant GPs are smaller.

Components of gas masks

The internal design of gas masks depends on the type of device. The main constituent elements of the filtering GP are:

- Face part (helmet-mask).

- Removable filter box.

- Inhalation and exhalation valves.

- Intercom.

Insulating gas masks, instead of a filter box, are equipped with a hose that connects to an air regeneration cartridge or oxygen cylinder. In addition to these parts, the design includes: an insulating cover, a launch briquette, a breathing bag, a bag.

The device of the front part of different gas masks is different. Some models hermetically cover the face, ears, back of the head. Other types (especially military gas masks) have ear holes or cover only the face. This is done in order to improve audibility in tactical conditions.

The principle of the gas mask

Consider how a filtering gas mask works. The main component of the GP is a filter box. Getting into it, the air goes through several stages of purification (it depends on the filter used). Activated carbon is used as an absorber of hazardous substances. Due to the porosity and the increased active surface of coal, it retains some substances inside itself.

However, not all SDYAVs are delayed by a conventional carbon filter. In this case, a layer with a chemically active substance (silver oxide, copper oxide) is added to the activated carbon layer. This provokes additional reactions. To protect against smoke and aerosols, special types of filters are used: anti-aerosol filters. They consist of a multi-layer fibrous material that retains particles.

The insulating models of gas masks are based on a different principle of operation: they do not filter the surrounding air, but allow a person to breathe without it. A regenerating cartridge and a breathing bag are located in a special frame, from where air is supplied to the respiratory organs through a system of pipe connections. The disadvantages of the power supply are limited time of use and heavy construction.

How to put on a gas mask

They teach how to correctly put on a gas mask at school in the lessons of Life Safety. This is a simple sequence of actions. Their knowledge will help save lives for yourself and your loved ones. Workers in hazardous industrial plants should study the instructions for gas masks.

It is generally accepted that there are three provisions of protective equipment: "traveling" (in a special bag), "ready" (intermediate state) and "combat" (direct use).

Instructions for putting on a gas mask and bringing it to a state of combat readiness:

- Remove any foreign objects from the head.

- Close eyes.

- Hold your breath.

- Remove the gas mask from the storage bag.

- Take the front part at the bottom so that the thumbs are outside the mask and the rest are inside.

- Insert the chin into the bottom of the protector.

- Put on the front part with a quick movement.

- If wrinkles or discomfort appear, repeat the operation again.

- Open your eyes, start breathing.

How to choose a gas mask: basic rules

First you need to decide on the type of gas mask. GPs are represented by various models of the filter type. They can differ in the degree of protection, filter features, additional attributes for comfort and safety. However, the main challenge is to find the right GPU size. Its efficiency and reliability directly depend on this.

To determine the correct size of the device, measure two main parameters: head circumference in the vertical and horizontal part. The horizontal measurement is taken through the eyebrows and the top of the ears, the vertical measurement through the crown and chin. Both indicators are summed up, and as a result we find out the size of the gas mask: from 0 to 4.

- Up to 92 - 0.

- From 92 to 95.5 - 1.

- From 95.5 to 99 - 2.

- 99 to 102.5 - 3.

- More than 102.5 - 4.

Some gas masks have adjustable straps that can be adjusted slightly. Otherwise, it is necessary to select it as accurately as possible. These straps are usually provided on GP models for children and adolescents. Correctly selected size will provide not only safety, but also convenience in use.

Don'ts when wearing

When wearing a gas mask in emergency conditions, it is strictly forbidden to allow it to depressurize.

Sometimes the desire to get rid of a heavy and uncomfortable device is too great, especially in conditions of physical activity or insufficient oxygen supply to the lungs.

The filter box allows a small amount of oxygen to pass through, which is inconvenient for people with respiratory diseases. However, it should be remembered that even a small ingress of poisoned air into the gas mask will make its use meaningless.

What are the types of gas masks, what is their purpose and benefit

Gas masks protect the respiratory organs, eyes and skin from the ingress of toxic substances contained in the inhaled air.

There are a huge number of different types of gas masks and it is difficult for an ordinary person to understand their purpose and use, so we will tell you everything about what they are, what they are for, what different brands of models protect from and how to choose the right device for the field of use.

general information

At the beginning of the 20th century, the world has changed. And we are talking not only about the collapsed empires and world revolutions, but also about the globally shaken foundations of military affairs.

And all because the German troops, during the First World War, began to use a new type of attack - gas (or rather, chlorine).

This weapon did not kill quickly and very painful, and also differed in a huge (in comparison with other technologies of its time) radius of destruction.

Just a couple of weeks after the first use of this weapon, the first prototypes of personal protective equipment appeared From him. At first, they rescued using bandages soaked in acid that neutralized chlorine, then they thought about more reliable protection.

Almost a hundred years have passed since then, and chemical weapons have become one of the most widespread weapons of mass destruction. But personal protective equipment from it also did not remain in place and is actively used by both the military and civilians around the world. Let's talk about them.

Gas masks are the primary respiratory protection against toxic substances such as gases, volatile chemicals, as well as bacteria and viruses.

Differences from respirators

Personal chemical protective equipment is divided into two types - gas masks and respirators.

And very often non-professionals confuse them with each other, especially since many models of devices are indeed extremely similar.

In order not to be mistaken in the choice, we propose to study the varieties, device and purpose, and the rules for using a filtering gas mask and a respirator, how they differ, and from what hazardous substances a gas mask can protect.

So, the difference between them is that the respirator covers only part of the face, or rather, only the nose and mouth, leaving everything else open, while the gas mask covers the entire scalp and protects the respiratory system from the ingress of harmful and hazardous substances.As a result, the use of respirators against substances that can enter the body through the skin or react with it is unsafe. These substances include acid gases, inorganic corrosive gasesas well as many other hazardous materials. Do not forget about radiation dust, from which a gas mask can save, but a respirator is no longer.

Definition and application

Filtering and isolating devices are part of the compulsory kit those civilian and military professionals who work with volatile toxic substances or are at risk of chemical poisoning. Also, the use of various personal chemical protection equipment is mandatory in case of man-made disasters.

The device consists of a helmet-mask that covers the entire head, and breathing element - filter box or compressor. And if the filter box in most cases is located directly on the mask, then it is customary to hang the compressor on the belt and tightly connect it to the mask using a hose.

Classification

There are several different classifications of the device and we will try to consider all of them.

Let's consider what filtering and insulating (including hose) gas masks are intended for, what their action is based on, how they differ from each other, their purpose and photos. The main purpose of gas masks for all varieties is the same - it is protection, but there are certain specifications and conditions for the implementation of this function.

According to the method of protection and type of construction, two types of gas masks are distinguished - filtering and insulating:

- Filtering... A filter box is used, designed to preserve organs from those threats, the entry of which into the respiratory tract can be stopped using a mechanical filter or a chemical reaction. When using a gas mask of this type, its owner continues to breathe ambient airSuch devices protect at any given moment only from a certain type of threat, since the filter boxes are not universal, and also require replacing these boxes as they are used up. The service life of the filter varies from several days to a couple of tens of minutes and depends on its type, as well as on the level of environmental pollution.

- Insulating... A device with a compressor box is a much more advanced degree of protection, which is also completely universal. The oxygen-insulating gas mask is designed to protect the respiratory system in conditions of lack of oxygen. The difference between insulating gas masks and filtering masks is that they owners breathe non-surrounding atmospheric air, and clean air from another source. Such masks are divided into two types, according to the type of this source - self-contained breathing apparatus (when the owner has his own compressor box, which contains a compressed air cylinder) and hose respirators (when air is supplied through a hose from an external source, such as a compressed air line). Also often used combined options, when the main supply goes through the hose, but in case of an accident there is also a small autonomous cylinder.

Isolating gas masks look like this photo:

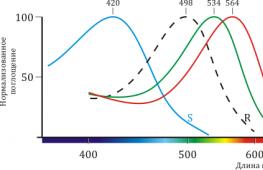

Filtering masks are also distinguished by the type of protection, which is usually indicated by letter and color markings on the filter box.

The number after the marking indicates the level of protection to increase - "1" protects only from low concentrations of gases (up to 0.1%), "2" already allows you to breathe in an atmosphere with 0.5% of toxic substances, and "3" allows you to survive in place with a concentration of more than 1%.

Gas mask marking can be composite if the filter protects against more than one type of toxic substances:

- "R", the color of the gas mask box is white. These filters protect against foreign particles in the atmosphere. And if "P1" protects only from coarse dust, then "P3" can already withstand suspensions, fogs, bacteria and viruses.

- "A", Brown color. Protection against organic gases and vapors with a boiling point over 65 ° C.

- "AX", Brown color. The same, but for substances with a boiling point less than 65 ° C.

- "IN", color - gray. Protection against inorganic gases including chlorine, fluorine, hydrogen sulphide, etc. Does not protect against carbon monoxide.

- "E", yellow color. Protection against nitric acid vapors and acid gases.

- "TO", green color. Protection against amines - volatile ammonia derivatives.

- "NO", color - blue. Protection against nitrogen oxides, in particular against highly toxic NO2.

- "Hg", color - red. Protection against mercury vapors and volatile organic compounds.

- "Reaktor", Orange color. Protection against radioactive elements, including iodine and methyl iodine.

- "SX", color - purple. Protection against chemical warfare agents - sarin, soman, etc.

- "CO", color - purple. Carbon monoxide protection. Such filters increase their weight as they work out and the number after the marking indicates the maximum permissible deviation from the norm, after which the filter must be replaced.

There is also a classification by scope, according to which the types of gas masks are distinguished into:

- Military... Military models of devices are highly reliable and versatile and are part of the standard equipment of a soldier, and are also used by some specialized structures, such as the Ministry of Emergency Situations.

- Civil... Issued to the public in case of emergency. Quite cheap to manufacture and generally reliable. Not very different from military models, except for lower quality materials.

- Industrial... Special gas masks for employees working with hazardous substances. Usually built into OZK or a suit of a similar protection class.

- Children's gas masks - these models are used to protect the respiratory organs of children and adolescents, they are distinguished by reduced sizes. There are also devices for babies - rubber chambers with a metal frame, in which the child is completely placed and air is pumped with bellows.

Terms of use

Civilian population only filter devices are issued, so the manual describes exactly them. Those who are entitled to an isolating model by position or occupation receive separate instructions when it is issued.

The device, in conditions of a possible threat, is carried in a special bag on the stomach. The buttons on the bag must be unbuttoned. If necessary, you can study the instructions on how to put on a gas mask correctly:

- Hold your breath.

- Close your eyes.

- Take out the gas mask from the bag with your left hand.

- Remove the plug from the filter box.

- Place your thumbs on the outside of the sides of the mask and the rest on the inside.

- Apply the bottom of the mask to your chin.

- Exhale.

- Pull the gas mask up sharply and spread it out so that no wrinkles remain.

- Open your eyes and adjust the position of the gas mask so that it does not interfere with the view.

- Move the bag on its side so that it does not interfere with movement.

If the device was given to you for a long time, then keep it clean - do not forget to wipe the mask lensesespecially in safe places where you can remove it. Also, keep an eye on the level of working out of the filter box (it will be written on it after what time or under what conditions it should be changed).

Most importantly, try to get out of the infected area as quickly as possible, especially if your clothing leaves skin exposed.

A gas mask is a means of personal protection of the respiratory system from harmful substances in the atmosphere. In simple terms, a gas mask is a device that allows you to protect the human body from poisoning by poisonous impurities while in a dangerous area.

Gas masks: varieties and design features

Gas masks come in several varieties depending on many factors. The two largest groups into which all gas masks can be divided according to their method of protection are filter type and insulating gas masks.

A gas mask of any kind includes a front part and components responsible for cleaning or supplying purified air to the respiratory system.

The front part of the gas mask is made in the form of a full-face sealed mask (or helmet) made of green or black rubber, and in some modifications of durable thermoplastic. One of the main distinctive elements of the front part is the viewing glasses (spectacle assemblies).

Gas masks, depending on the purpose, can have a mask with a standard arrangement of glasses, with a frontal one, with an increased viewing angle, or a mask with a panoramic glass.

In addition to the spectacle unit, the front part of the gas mask includes inhalation / exhalation valves, and some models can be equipped with an intercom, a device for receiving liquids.

Filter-type gas masks are equipped with replaceable filters, which are responsible for screening out dangerous particles in the contaminated air and preventing them from entering the body.

Since there can be a lot of toxic substances in the atmosphere, and they all differ in both their composition and concentration, the filters used in gas masks are also always different.

A filtering-absorbing box is responsible for cleaning the air from impurities, which consists of an anti-aerosol filter (retaining dust and aerosols on its fibers) and a charge of active carbon (absorbing harmful vapors and gases).

Gas masks of this group work only on the principle of filtering polluted air and are not capable of producing pure oxygen, therefore, their use is impossible if there is less than 17% pure oxygen in the polluted atmosphere.

Insulating gas masks, instead of a filter element, have a regeneration and air purification system: a regenerative cartridge, a breathing bag, an oxygen cylinder. The device of such gas masks also depends on their purpose and modification.Apparatus of this kind completely isolate the respiratory organs from the environment. The gas mask begins its work after activating the trigger of the regenerative cartridge, which releases the first portions of oxygen.

The principle of operation of insulating gas masks in total boils down to the following: the exhaled air enters the regenerative cartridge, in which it is purified from carbon dioxide and enriched with oxygen.

The breathing bag serves as a container for purified air, from which it then enters the respiratory system through the inhalation valve. Since these gas masks completely exclude any interaction with a polluted atmosphere, they can be used with any composition and concentration of harmful substances.

There is another type of insulating apparatus - hose-type gas masks.

A distinctive feature of such gas masks is the method of supplying clean air to the body, carried out through special hoses, from a clean atmosphere.

The operation of hose devices is limited by the length of the hoses themselves, which can be 10, 20 or 40 m. Gas masks of this type are widely used when working in wells, tanks and other confined spaces.

Filtering and insulating gas masks can have the same purpose, that is, the ability to protect the body from the same harmful substances in the same conditions. Here it is worth paying attention to the peculiarities of using each type of apparatus.

Filter masks are easier to use, have less weight and, accordingly, exert less pressure on the face. The operating time in such gas masks depends on the operating time of the filter, which, after working out, can simply be replaced with a new one and continue working.However, filter-type gas masks can be used only if the composition and concentration of harmful impurities is accurately known, as well as if there is a proportion of pure oxygen in the atmosphere necessary for a person.

Isolation devices can be used in any case - when working with an unknown composition of toxic substances, with a lack or complete absence of oxygen.

But, despite such a universal protection, still more often preference is given to filtering gas masks, since isolation devices have a very complex structure and an untrained person will rarely be able to use them correctly. The duration of the insulating gas mask is limited by the supply of an oxygen cylinder, the refueling of which cannot be compared in time with changing the used filter. By virtue of their design, isolation devices are much heavier, which makes them difficult to use for a long time.

Gas masks and their scope

If we talk about the field of application of gas masks, then we can distinguish civil, industrial, military gas masks.

Civilian gas masks are intended for use by the general population when evacuating from a contaminated area, or for carrying out the necessary work in a contaminated environment.

Gas masks of this type were widely used in accidents associated with bacteriological, chemical, radioactive air contamination.

Civilian gas masks belong to the filtering apparatus, usually they have the simplest modifications, which ensures easy donning and use.

Gas masks for industrial use are intended for use in industries of a specific orientation in cases of accidents or unforeseen situations.

Such gas masks are equipped with enterprises whose activities are related to the use or storage of a certain type of hazardous substances.

Due to the fact that potentially dangerous contaminating substances are known in advance, these gas masks have a narrow focus, but thereby a higher degree of protection.

Military gas masks are used during training exercises or fighting. Such devices have a more complex design and are usually equipped with both intercom devices and devices for receiving liquids. Gas masks for military use can be either filtering or insulating and are suitable for use on any type of contaminated facility.

What the gas mask protects and does not protect from

One of the most popular questions of people who have not had to deal with gas masks is whether there is a gas mask that protects against everything. Filter-type gas masks have a specific focus on protection against a specific type of substance, which is determined by the filters used.

If a gas mask is used in an enterprise working with certain hazardous substances, then the employer, in case of accidents or unforeseen situations, purchases gas masks that protect against these substances.

For the civilian population, gas masks with a standard set of filters are provided, the action of which is aimed at protecting against many harmful emissions - aerosols, dust, vapors and gases. However, an additional filter must be purchased to protect against carbon monoxide.

And do not forget that the use of filtering gas masks is possible only if the necessary proportion of oxygen in the contaminated environment is available.Insulating type gas masks protect against all types of substances and at any concentration, including such masks can be used in the complete absence of oxygen.

However, due to their complex design, such gas masks require preliminary training before using them, so the untrained civilian population simply cannot cope with them.

In addition, any gas mask exerts pressure on the face, on the head, noticeably complicates breathing, and in devices of the insulating type, due to their greater mass, these properties are increased.

As a result, we can conclude that with a properly selected gas mask for its purpose and competent use of the device, it reliably protects the body from poisoning with harmful substances as part of its protective effect.

But if the filter is not designed to protect against certain substances, or with a suitable filter, the gas mask is not used correctly, for example, poisoned air enters the under-mask space, bypassing the inhalation valves, due to a violation of the tightness of the mask or a malfunction of its other parts, then use the gas mask becomes completely useless.

Gas masks: how to put on, apply, check

In order for a gas mask to meet its purpose, it is necessary to use it correctly, including putting it on, storing it and checking its integrity and performance in a timely manner.

A gas mask is put on with closed eyes and with held breath. First of all, the lower part of the mask is applied to the chin, leaving only the thumbs outside the mask, and then, with a sharp movement, is put on the entire head. The mask should not form any folds, but, on the contrary, should fit snugly to the face, maintaining complete tightness.

It is important to check the gas mask both before using it and during storage. Devices with mechanical damage, missing or malfunctioning of any components, as well as gas masks not of their size, are not allowed for use.

Using a visual inspection before using the gas mask, you must make sure that there are no chips and cracks on the glass, holes, tears or scratches on the mask, rust or corrosion on metal parts, including the filter box.

If any kind of damage is found, this part must be replaced.

When using filter-type gas masks, it is always necessary to monitor the filter life and replace it in a timely manner. In the case of isolating devices, it is not allowed to use them with a spent regenerative cartridge, as well as to replace it while in the contaminated area. It is recommended to store and carry gas masks in a specially designed bag.

Popular models of gas masks

Gas masks GP

Gas masks for the civilian population GP7 are among the most popular models and are designed to protect against aerosols, vapors and gases of military toxic chemicals, from radioactive substances, biological aerosols, emergency chemically hazardous substances, including ammonia and organic compounds with a boiling point below 65 ° C.

A mask of this kind of gas masks can have both a spectacle unit with an increased viewing angle and a panoramic glass. Additionally, the models can be equipped with a device for receiving liquid.

Children's gas masks

Children's gas masks are also civilian, and can be modified for school children up to 16 years old and for preschoolers from 1.5 years old. The difference between a children's gas mask is the size of the front part.

Gas masks PPM and ShMP

ShMP gas masks have a helmet-mask made of durable rubber with a standard goggle assembly and differ in the characteristics of the filters used, depending on which they can protect against smoke, aerosols, vapors and gases of organic and inorganic substances, etc. ShMP gas masks filters and can have 1.2 and 3 class of protection.PPM gas masks also, depending on the filters used, have various protection against various kinds of hazardous substances. The PPM gas mask is equipped with a panoramic glass, a mask in three sizes, inhalation and exhalation valves, an intercom and an adjustable elastic headband and can be used with any filter.

Gas masks PSh

Hose gas masks are very widely used in places with a minimum area of \u200b\u200bcontamination, protecting the body from toxic substances by isolating the respiratory system from the harmful environment. These masks can be used in confined spaces with insufficient or no oxygen.

Gas masks of this type have a very wide range of models, the differences in models of which are the length of the hose (10, 20, 40 m), the type of face part (helmet-mask or panoramic mask), the presence or absence of a hose reel, the type of air supply (natural , hand or blower), etc.

Gas mask IP

The IP gas mask is an insulating type gas mask, the basis of which is the action of a regenerative cartridge.

The air exhaled by a person enters the regenerative cartridge, the substance of the cartridge absorbs the carbon dioxide and moisture contained in it, and instead releases the oxygen necessary for breathing.

The oxygen-enriched breathing mixture enters the breathing bag. When inhaling, the mixture from the breathing bag repeats this cycle again.

Modern gas masks: classification and types

Gas masks are necessary to protect the area of \u200b\u200bthe eyes, respiratory organs and skin of the face from the poisonous effects of nerve gases and other poisonous substances. Such compounds can be released into the air during man-made disasters and accidents or military operations.

The history of the development of personal protective equipment goes back several centuries. Now there are new, improved gas masks used in various fields. Their classification includes many different modifications and types, in which common man it can be difficult to figure it out.

In this article, we will look at the most common types and models, understand their purpose, consider the distinctive features and give information on how to use them correctly to obtain optimal protection.

Types of modern gas masks

Modern protective devices are externally a helmet - a mask with a special breathing element (filter or compressor). It should cover not only the face, but the entire head. The filter box is included in the mask itself in most models, but the compressor is attached to the belt. A hose is required to connect it to the helmet.

Such devices for air filtration are mandatory equipment for civilian and military specialists whose activities are associated with toxic substances. In addition, gas masks are mandatory for use during emergencies with the release of chemical vapors.

By the type of device and the method of providing protection, there are 2 main types of modern gas masks:

Gas mask GP-7

In such devices for air purification, a filter box is used, which carries out mechanical filtration. However, they are not versatile and do not protect against all existing chemical threats.

They need to be replaced after the expiration of the specified period of use. The term depends on the degree of air pollution and the type of toxic substances. It often ranges from 10 minutes to several days.Gas masks of this type are marked on the box by which you can determine the type and degree of protection. Numerical designations indicate the level of concentration of harmful compounds in the environment at which this gas mask will be able to protect.

For example, a device marked "1" can only be used if the vapor concentration is not more than 0.1%, that is, with a low contamination level. The number "2" allows you to breathe without risk at a level of up to 0.5% of the concentration of toxic compounds.

Oxygen isolating gas mask (KIP)

They include a box with a compressor. This type is considered more reliable and provides optimal protection for all levels of pollution and types of toxic substances. It can be used in situations where there is a lack of oxygen in the air, for example when fighting a fire.

The main distinguishing feature of the filtering means of protection is that when breathing is not used atmospheric and purified air, but pure oxygen obtained from another device.

According to the method of obtaining air, insulating gas masks are divided into:

- Autonomous - using a cylinder with a supply of compressed oxygen

- Hose - air from a pipeline or other source is transmitted through the hose

There are also combined device options. They are especially in demand during emergencies. In this type, the main type of air supply is hose, but there is also a cylinder that can be used if necessary.

Classification of gas masks by scope

Protective devices are used in a wide variety of applications. For this factor, there are:

Specialized models are versatile and reliable. They are an indispensable element of a standard kit for equipping specialists who are not only in military service, but also on alert in emergency response units, such as the Ministry of Emergency Situations.

In modern military gas masks, it is extremely important that the employee can clearly hear orders and speak, therefore the mask itself has a sealed intercom. In addition, the ear section is released from the sealing to ensure optimal performance of the intercom.

A distinctive feature is a longer service life in comparison with civilian models. The protective glasses for the eyes are covered with an additional film designed to protect against the negative effects of light radiation. In some military models, an additional autonomous source of air may be present in the kit.

They can be purchased independently, and they are also issued by local authorities in case of a health hazardous situation. Their price is quite affordable. Reliability is average. In design, they do not differ much from military models.Used by employees and workers whose work activities involve contact with hazardous substances or vapors. Most often they are built into a protective suit.

Suitable for young children and adolescents. Smaller. In addition, there are special models for babies (up to 1.5 years). They are rubber chambers with a reliable frame. The child is placed inside completely, through special transparent holes. These devices are selected not only based on age, but also the height of the child.

Modern models are varied, and you can choose the most convenient option for yourself. There are options with intercoms, as well as with wider lenses for the eyes, providing a larger and clearer view. All models have a good level of moisture resistance.

How to use a gas mask correctly

The protective functions of an individual filter medium depend not so much on the model chosen as on the correct use and dressing.

There are 3 main options for wearing a protective device.

- Hiking. Used in non-hazardous situations where there is no risk of infection. A gas mask in this position is usually worn at the waist level on the left.

- Ready. It is used in the situation of giving a warning signal "Alarm", as well as in case of an existing threat of CW entering into environment... You should proceed to unfasten the valve, then fix the device with a special cord.

- Combat. This option is applicable when the command "Gases" or in a situation of detecting the first symptoms of contamination of the area with chemicals or declaring a "chemical alarm".

You need to wear a gas mask according to certain rules. Grasp the mask with both hands by the straps, with your thumbs inside. Tilt your head forward slightly. Bring the bottom of the gas mask to your chin, and pull it over your face. Tuck the ties on the sides of the helmet behind the ears. Tighten the back cords. The mask should cover the entire face tightly.

If you need to put on a gas mask on an injured person or an unconscious person, then it is more convenient to do this by kneeling down. Raise his head and place it on your lap. If possible, the injured person should be jailed. Take the mask out of the bag, grab its bottom with your hands and bring it to the chin lip