Bosch gas boilers: overview, technical characteristics, disadvantages

__________________

Gas boiler Bosch

Please provide a list of the minimum settings to reduce clock cycle. The room thermostat is not yet usable. And is it always necessary to adjust the gas valve during commissioning? Bosch Gaz 6000 W WBN 6000-24 boiler. The heated area is 120 sq. m. Installed capacity 50 percent. The coolant temperature is 70 degrees. It is heated so far only by radiators of the first floor in the amount of 5 pieces. The burner switches on and off every 5 minutes approximately.

It is necessary to reduce to a minimum of 30%, it is possible to increase the time between switching on to 10 minutes. and you can also try the temperature range incl. / off change. Setting the gas valve is required.

Malfunction with EA error for Bosch 6000 35 kW boiler. At first it was thrown off and it was launched. Already the fifth time in a week and a half. I checked it last night. Today at lunchtime I stopped by to check EA's error again. The error is cleared, but this time the tool clicks but does not start. So five times before the error. I had to turn it off and unplug it. After that it started. Whether it works or not, I don't know. I don't live in the house yet.

This error is only cleared when the power is turned off, so there was no point in trying to reset. Ground the unit if not grounded. Set the fan stage to a higher value (for example, I have 5 instead of the required 2 according to the instructions).

The double-circuit boiler 6000, chirps when it starts and stops, so it's scary. The device is new, I looked at the heat exchanger, washed it, just in case. Did not help.

Do not torment the burner, the sound comes from the fan turbine when it is turned on / off. Remove the fan and adjust the balancing clips on the turbine so that they do not cling to the housing or tighten the nut on the turbine if it is loose.

Why is water about a glass by volume drained from the overflow pipe on the 6000 boiler at intervals of 20-30 minutes? The make-up valve is closed. Does everyone have one or the unit is faulty?

As practice shows, in 9 out of 10 cases the boiler has nothing to do with it, it is just part of the system. It is necessary to call the specialists and look at them comprehensively.

Tell me, if there is a thermostat in the boiler that opens and closes the contact, it cannot be connected to the Bosch 6000? Or should only the boiler temperature sensor be connected to the device?

To this only the sensor. I have an apartment of 32 meters with a gas boiler Bosch GAZ 6000 W. A couple of people in this apartment building there was a mistake on it. As a result, very dirty water was drained from the heating, because it was filled, when there was still no water and a completely new building, a new quarter. I want to drain the water from the heating and fill the circuit with a new one, but in my passport I cannot find how to do this, in what modes. The diagram shows the make-up valve and the drain hose. How to properly drain and fill the heating water?

As I understand it, you have a two-circuit model. You cannot drain directly from the boiler. For this purpose, the heating system must have a drain valve at the lowest point of the system. If there is such a tap, then there are no problems - open it and Mayevsky's taps on the radiators and drain. Water will be drawn out of the boiler heat exchanger by discharging. If something remains there, then only in the expansion tank - it's okay: in the expansion tank, water does not participate in the circulation. The drain hose is the drainage of the safety valve when the system pressure is too high.

Bosch 6000, when the power supply is turned off and on, does it start itself or do you need to manually start it up?

All boilers, including yours, start themselves when the electricity supply resumes.

Tell me about bosch bw 24c classic. It worked for 2.5 years regularly, now when the hot water is turned on, the burner ignites and immediately goes out and so on several times in a row, then it lights up, but it does not work stably, that is, the water goes, it is hot, then cold. It is terribly inconvenient to wash. Sometimes it even goes out and does not light up. What can be, where to look, or go straight to the specialists?

Better service.

Bosch GAZ 6000 boiler with coaxial. How to choose the default fan speed at the first start? The device is connected for heating and hot water supply. Email I did not connect the power supply, I did not purchase the stabilizer, since there is an example of the operation of a Korean unit without a stabilizer for 8 years. In general, any recommendations for the first launch are interesting.

Install the stabilizer.

Bosch 6000 24H does not heat the boiler. What's the question?

Change parameter 2.4E. Set to 0.

I bought a single-circuit Bosch 6000 and an ACV 130 boiler. How to combine them? The instructions only describe the double-circuit. From the water it is clear, but where to connect the temperature sensor, and which one is necessary? NTC temperature sensor art. Will 87004000140 fit?

It's a thermistor! Naturally, there are no contacts there. A semiconductor that changes resistance with temperature. It works on the falling part of the current-voltage characteristic, which is why it is called “Negative Temperature Coefficient”. What kind of boiler, and the sensor and the boiler do not make a difference.

A question about a room regulator, I don't know which one to choose. Bosch boiler 6000 24s, heating TP, flow temperature 45 degrees. Everything would be fine, the unit does not clock, heats up to 45 and works at this temperature for hours, as I understood on modulation. It consumes little gas, the floor is pleasant. But it is not very cold outside now, and the temperature in the house in a few hours reaches 25-26, but the boiler continues to work. We have to switch it back to summer mode, and so about 1-2 times a day. I need the house to be 23, and it turns off, but at the same time, so that the thermostat does not control the flow temperature, and modulation, too, the boiler is already coping with it well. Which regulator is suitable, and are there any?

This means a simple on / off thermostat is needed. Better electronic with small hysteresis. + -0.2 degrees. There's a conventional output relay in the thermostat. When the relay is closed, an analog of the jumper is just obtained, which by default is in the unit at the thermostat connector terminals. Everything as you wanted. It will maintain the temperature, but there will be no power control, etc. On the boiler, this is a special input for the thermostat. He knows how to handle it.

Last year, AOGV-120 was accidentally replaced with a two-circuit Bosch 4000 with a closed camera in a private house. They decided not to change the heating system (frosts set in). Somehow they overwintered, although the system was old and heavily airy, they could not push it to normal. In the spring, on their own replaced the system with polypropylene and aluminum radiators Royal termo 350. Tehelman's system. The system works with a room thermostat. Doubts plagued. With the old system, I did not notice gas savings in comparison with AOGV (I worked without automatic equipment). It is almost clear that the system is not for a modern machine. Tell me if you need to adjust the boiler? The servicemen said that everything was set up and there was no need to touch anything. When working with a thermostat, what temperature should be set? I got used to the fact that the AOGV burned in manual mode constantly, when it was necessary to increase, decrease the flame. And now he is trying to set the regulator to 1-2. It seems to me that this is not correct, the room heats up longer, accordingly it burns more gas, and for old people the main thing is saving. They really do not like that all this shakes on the counter (numbers on the stabilizer and light bulbs on the boiler). Do not retell how many flaws there are in this model. Please give me a hint about the settings and temperature (to save gas). House 70 sqm, radiators in a circle, heated evenly. Yes, still, what pressure should be kept in the unit?

My model w6000, at a set supply temperature of 45 degrees, switched to the mode of maintaining a small flame, but for a rather long time. Those. the boiler tries to work longer, but with low power, than to heat up strongly and turn off. And I think the first option is more economical, since he knows better. A properly adjusted gas pressure device is 90% of correct and stable and economical operation. It is impossible to tell by the gas settings, this should be done by competent commissioners with a pressure gauge. If you mean setting up the boiler according to the parameters or adjustments available to the user, then this is all written in the instructions.

Boiler 6000, new building, 80 squares. The problem is as follows: He does not keep the temperature. That is, at a low pressure, boiling water flows, at a high temperature, it begins to float. I summoned the masters several times. It all started with boiling water going to the heated towel rail, it was fiery. Then he gave an error E2, E9. On the unit, the temperature rose above 70 with the set 40 (I did not notice this before). The master came, rummaged, removed the rubber gasket so that the pressure was greater, advised to reduce the power. At first it was normal, but the temperature swam hard, it was impossible to set a constant, again it showed 70 and higher. Once again he began to torment the masters. As a result, they said that it is better not to mix with the apparatus in the mixer, to regulate the pressure. They advised to increase the minimum pressure of hot water. As a result, I set the power to 40% (it did not have any effect on boiling water), the pressure of the water could somehow affect it. Need to try setting the minimum and maximum power again?

There are only three reasons why your household water is overheating.

1. With normal flow, too much gas is supplied to the burner per unit of time.

2. At normal, correctly set gas pressure (maximum pressure, since the wall-mounted gas double-circuit boiler in DHW mode always switches to maximum power), the DHW flow is too small. Household cold water passing through the secondary plate heat exchanger heats up and becomes hot, that's what it is called DHW for short.

3.1 + 2. That is, the flow is small and the maximum gas pressure is too high.

There was a problem with the boiler, the specialist checked the water filter again, said that the pump was working normally, that the heat exchanger should not heat up so quickly, and then drop the temperature just as quickly, watched something, twisted it. Then he offered to reset the settings to the factory settings. I tried it, but it was of little use. It keeps 33 on heating, then the burner ignites, quickly heats up to 51 (45 is set for heating), then the gas turns off, as I understand it - the pump turns on, the temperature quickly drops to 33 and lasts until the next start.

Open hot water to full, full capacity. Set the DHW temperature to 60 C (this is not for long) If the flow is about 10 l / min and higher, then with a correctly adjusted burner, the temperature on the boiler should not float (but in theory you should not see 60). In DHW mode, the unit displays the temperature hot water... Now turn off the water and activate heating mode. If the temperature rises sharply and the burner shuts down then:

1. heating circuit filter.

2.the pump rotor and its speed should be 3.

3. Three Way Valve - No voltage applied to actuator.

3. Maximum power of the heating system.

How quickly does it raise the temperature in the heating circuit? In principle, it depends on the power consumption of the heating system, and its resistance, but given that it is not cold yet, it will rise quickly. Further, when the temperature rises, after reaching the set value, the burner does not turn off immediately, but works for some time, in your own words, creates an inertial heat reserve. Usually it is + 5K to the set value and only then turns off. Plus a 1K cast is fine. Here is 51 C. Then, after turning off, the system activates a delay from frequent turning on - by default 3 minutes and additionally introduces a temperature correction of -5K. Time delay is a priority anyway. that is, if the temperature in the apparatus dropped too quickly, for example, within 30 seconds it changed by 15 K, it will still stand for 3 minutes. A sharp drop indicates a high resistance of the heating system (and the boiler is part of it). At the same time, if after three minutes

the heating circuit has not cooled down to the set value, the burner will not ignite. If you want to see the constant maintenance of the set temperature on the display, ask yourself the question - which is more important to you than 45 C in radiators, or + 22 C in the room. The latter is more important to me.

It is true that the heat exchangers of all Bosch models are not covered with anti-corrosion paint similar to aluminum. Other manufacturers Viessmann, Vaillant, Ariston, Baxi have heat exchangers covered with a special protective anti-corrosion layer. Bosch boilers use pure copper and this is presented as an advantage that other brands do not have. Is this really an advantage or are these heat exchangers just cheaper and they just saved?

Copper is therefore used because it does not corrode. Well, because of its physical properties. And this "anti-corrosion" coating burns quickly enough.

When does the burner activate modulation - only when using a thermostat?

When the coolant temperature approaches the set one, the modulation turns on even without a room temperature sensor, but this process may be too short (before turning off) to notice it. When using an OT thermostat, modulation of the flame will also occur when the room temperature approaches the set one. When using an On / Off thermostat, modulation and thermostat triggering are not related in any way.

The double-circuit boiler bosch gaz wbn 6000W has been in operation for two and a half years without any complaints. Except for cycling on hot water heating. Have recently done maintenance, cleaned and adjusted. He stopped timing. Then, a couple of weeks later, the sight glass in the combustion chamber flew out. Glued in place. In the summer, it occasionally began to turn off with errors 60 and 70. By the fall, faults became more frequent. Now it happens, it turns off many times a day. Sometimes it works for two weeks. He opened and cleaned the fan, blew the pipes from the diffrele, disassembled, cleaned and reassembled the chimney, along the way slightly straightening it (there were slight bends in the knees). The fan seems to be blowing weakly outside. I ask you to help with practical advice. And give me an idea of \u200b\u200bhow to make an alarm to turn off the device.

If the fan is clean and the impeller is spinning quietly, then it is unlikely. Change the pressure switch.

Tell me how to make a sound alarm for shutdown in case of a malfunction?

Simple methods - nothing. Put a temperature sensor on the supply plus an electronic device, if the temperature is low, it beeps.

House 70m2 300mm foam block + 50mm mineral wool + facing with ceramic bricks. In the future I will add another 50-60 meters. On the first floor of the TP 33m2, radiators on the first and second floors. At this stage, the draw-off points are: kitchen and bathroom with shower. Then I will make 1 more bathroom. I plan to install BKN Dražice 125. There is no riser, so the boiler will be wall-mounted with a coaxial chimney. I considered various boilers. For the price, it attracts a bosch 6000, and besides, it has a 18kw model, and a bosch gaz 7000 has a minimum of 24kw, I think, with my areas it will often be tripped. For me, the main thing in the functionality is that from it you can set the temperature of the boiler water and for the future

connect some room thermostat or an outdoor sensor (the last 2 conditions are not a fact). Is there a difference in the quality of components between these two models? Maybe the place of assembly is different or something else?

Take the bosch gaz wbn 6000-18 and wstb 120 model.

As I understand it, the BKN can be connected to a double-circuit boiler in 2 ways: through a three-way valve and through a hydraulic separator. And in either case, as a consumer of the heating system (radiator), and it will heat up from the temperature of the heating system. This is understandable. Where to connect the DHW outlets of the boiler, or can they simply be muffled? I wanted to take a single-circuit Bosch 6000, but it is not available, and they offer a double-circuit. If the outputs are muffled, nothing will happen to the heat exchanger, will it not burn out quickly without water? And you don't want to keep the device always at the maximum, let the BKN just heat up for a little longer. Moreover, I took ACV Comfort 130, and he tank in the tank, I think, will keep the temperature longer than with a coil. The disadvantage is that all boilers of this brand have a maximum pressure on the heating circuit of 3 bar, in the boiler the safety valve is also 3 bar. They say that if the valve gets stuck, then your BKN will explode. And I still think about a double-circuit boiler, so that in case of a boiler failure, you will not be left without hot water supply?

These conclusions can be left open, they are only for sanitary water. Or you can build a backup DHW heating line. But I don't remember any cases of ACV boiler failure.

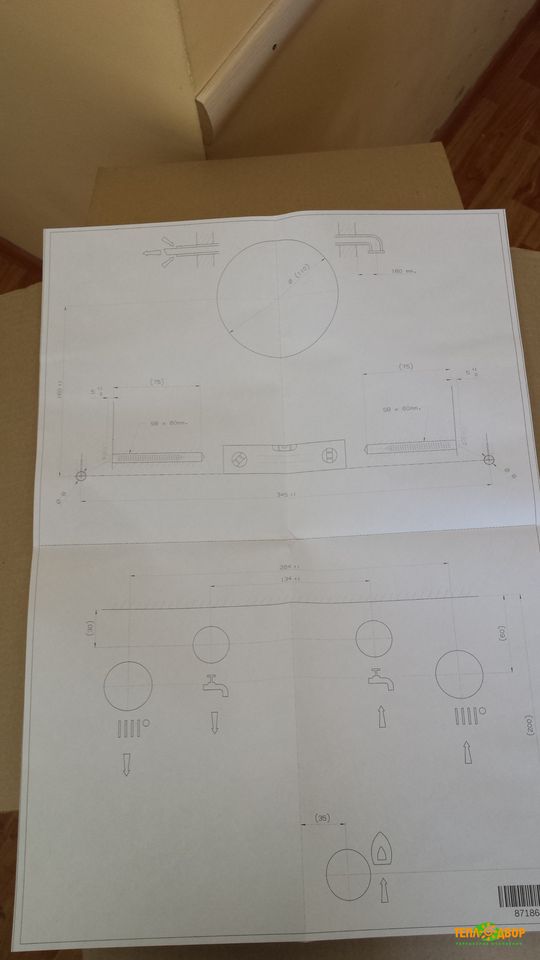

I ask for advice on two technical issues organization of separate smoke exhaust of the Bosch 6000 gas boiler:

1. Exhaust tract - does it make sense when going from "trousers" 80-80 through a tee with a condensate drain, to switch to a vertical chimney diameter of 100 mm? The cost of pipes 80 and 100 mm is close, on the whole pipe there will be a difference of 1200 - 1500 rubles, taking into account special stages. The chimney height from the tee connection point is 4500 mm, outlet through the roof of the building 5500 mm from the ridge, 10 degrees are taken into account.

2. Intake tract. The air intake will come from a cold ventilated attic. Before outer wall premises more than 4 meters, not an option; taking combustion air from the room is not an option. The distance from the point of intake in the attic room to the upper plane of the unit is about 1050 mm, including inside the boiler room - about 800 mm. In winter, this air duct could serve as a source of several problems, the main one being the flow of air with almost outside temperature into the device (very bad), and abundant condensation on this very air duct, flowing onto its body. Condensation is cut off by insulating the pipe with various kinds of thermal insulation, but at the same time it remains and is aggravated

the main drawback of the scheme is the cooling of the apparatus with the air of the outboard temperature. As a radical solution, I drew in my mind a diagram in which the chimney of a sauna stove (100-110 mm in diameter) plays the role of a supply air duct with a 300-500 mm long welded-on water register. Coolant circulation in the register - from CO, in a separate circuit. Difficult, but the result could be.

Please tell me which chimney kit to buy on bosch wbn 6000-24 c? It is necessary to go through a wall with a thickness of 375 mm, the outlet from the boiler immediately behind the wall, there is no need to lead anywhere else. Prices for Boshevsky chimneys have risen, I would like to buy something cheaper, from neva for example.

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

No. Replacing the board from a single-circuit boiler. And the valve body from a single-circuit model, as well as install a three-way valve.

When running on the regulator, can it be adjusted so that the pump does not shut off? It is connected with the fact that both floors and batteries work in the house at the same time (we love warm floors). I put Boshevsky cr 12005 today, and now I'm sitting thinking. The unit will reach the room temperature of 25 degrees and shut down completely. The room will cool down, the floors will certainly cool down too much. Later, when you turn it on, in order to heat it up to the set temperature again, not much time will pass due to the high temperature in the batteries and the floors will generally be a little warm all the time. How best to set up here? And the second question, I press the middle button with the letter P, the hot water icon appears on the display, its temperature and time. What does it mean?

The problem with choosing a boiler between Bosch 4000 b 6000. I know about the difference in heat exchangers, preferably with an open chamber with a branch to a vertical riser (there is a diameter of 130 mm). What slows down the choice:

1. 6000 with a closed chamber, which means you need an adapter with 60 mm plus aperture, the meaning of which is not yet clear, this is a minus

2. For 6000 a separate heat exchanger, this is kind of a plus

3.at 6000, at first glance, more complex settings, but there is no service in the district, this is a minus

4. Possibility of using with the AURATON 1300 room regulator (installed and operated with an old ferroli boiler). And there are no spare parts for any boilers.

Revealed the dependence of the operation of the ZWA24 boiler on the CO heating installation. If 3 or higher, it works like a clock. If 2.5 and below, then it is cut down on the first cycle or if you turn on the hot water by mistake of the pressure switch (something I tried to fight with before). Maybe this is due to the gas supply settings (once, instead of resetting, the unit was inadvertently transferred to the setting mode) or some other tricky process is going on there.

The apartment has a double-circuit boiler GAZ 6000. I additionally bought a room temperature controller OpenTherm CR12005 aka TRZ200. I connected it according to the instructions. It seems that the instructions for setting up it do not exist in nature, I somehow figured it out. The device looks like a worker. But I can't understand: the device is already in summer mode and the temperature in the room has dropped by 2 degrees, and the sensor almost does not give a command to turn on, turn on for a few seconds and turn it off. And without a sensor, the unit normally maintains the set temperatures.

Bosch 6000 single-circuit, gas outlet 3/4 ", flexible connection 1/2, respectively. I bought a transition, actually there are two questions:

1 - Wind the fum onto the boiler for transition or through the gasket.

2 - Will there be any problems because of the transition, as I understand it, there will be a decrease in pressure.

They started up a Bosch WBN 6000-24H single-circuit boiler, everything works fine, but a question arose, his heating works together with the summer mode, the master said it should be so. But I don’t understand something, it’s clear for a double-circuit, in summer mode, hot water is on, and the heating is off. How about this? The heating and summer mode icons are on and the heating is working. As I understand it, only one should burn, or one or the other. And how the summer mode is implemented in a single-circuit unit.

_______________________________________________________________________________

_______________________________________________________________________________

____________________________________________________________________________

_____________________________________________________________

_____________________________________________________________

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

Features. Installation and assembly. Automation components.

Technical specifications. Installation. Adjustment and check. Maintenance.

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but it gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

We installed and connected a Baxi Fourtech 24 F boiler. What is the pressure cold water allowed at the entrance to the DHW unit?

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for a three-way valve malfunction (there are no leaks from the radiators)?

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed, etc. Is it possible to really reduce the power?

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

Malfunction in the operation of the boiler, the green LED (power supply) is flashing, the instructions say that the thermal protection has worked, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

Installed and connected wall-mounted boiler Electrolux Basic Xi. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

Malfunction of the Koreastar boiler. Heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

The wall-mounted double-circuit boiler is designed not only for heating rooms, but also for quick preparation of hot water. Thermal power of the model is 24 kW, which corresponds to the maximum heated area up to 240 sq. m. However, taking into account the required stock, it may be less. Other equipment characteristics:

- Combustion chamber type - closed;

- Installed heat exchanger - plate;

- Number of circuits - 2 (heating and hot water supply);

- DHW circuit productivity - 11.4 l / min;

- Chimney diameter - 60/100 mm.

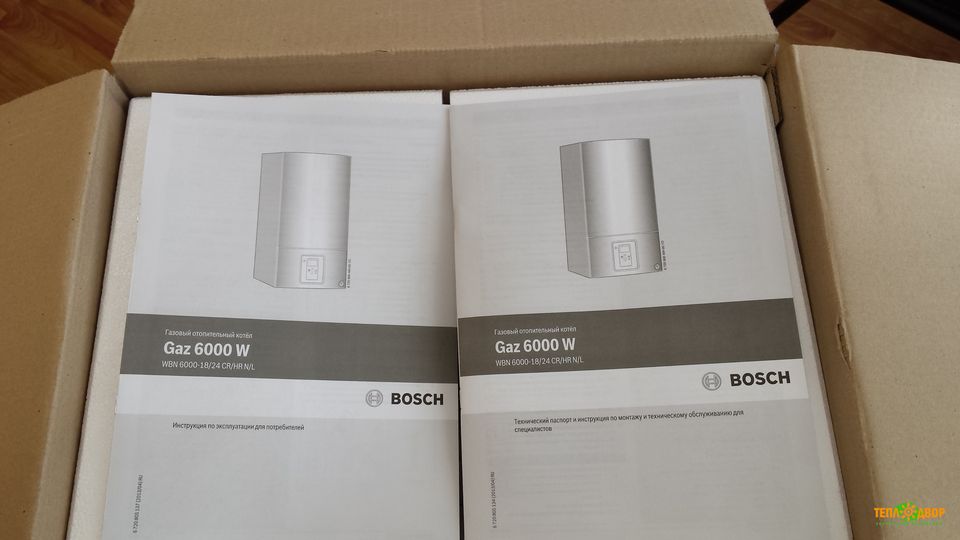

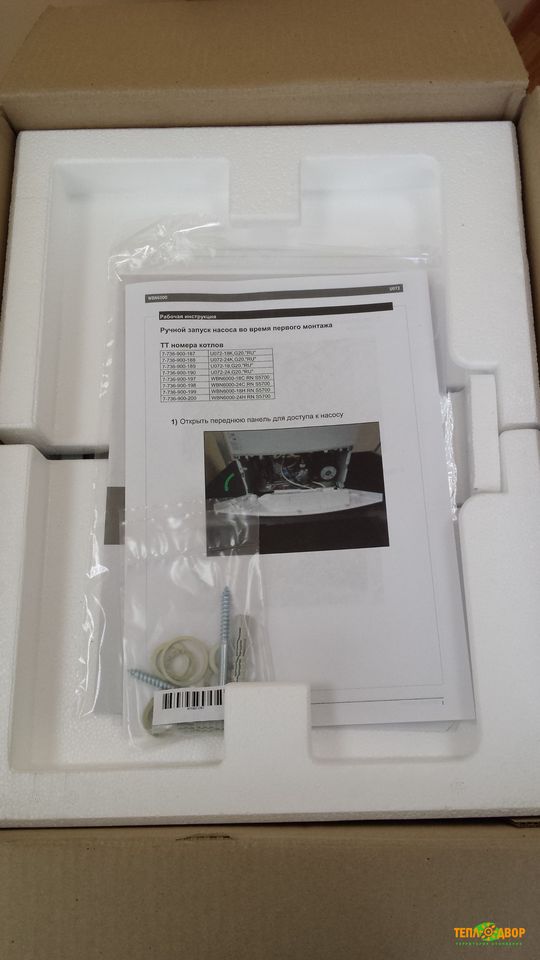

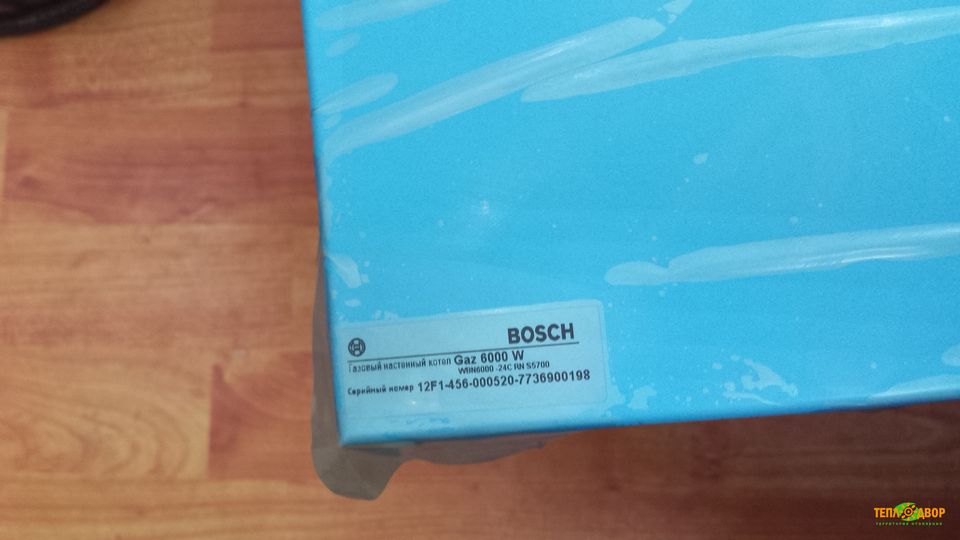

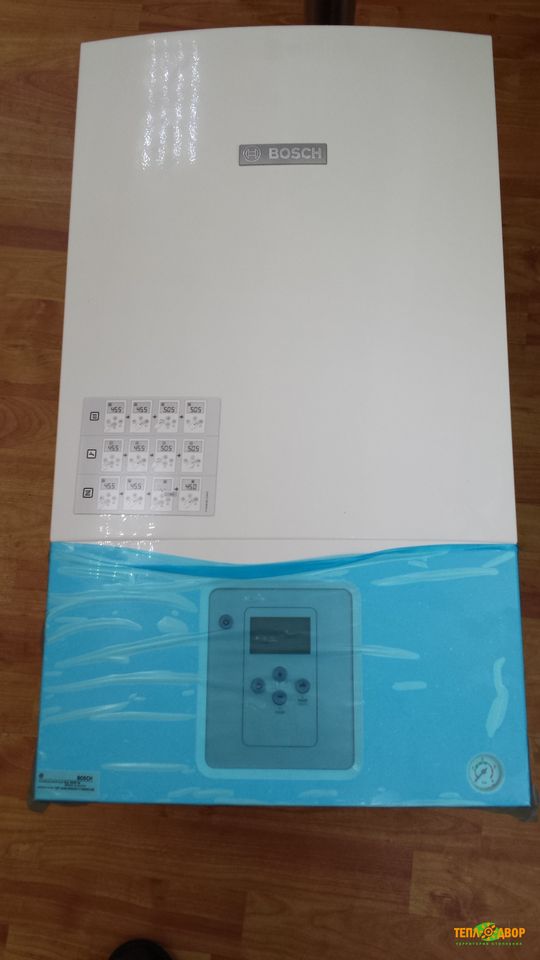

Having received a Bosch Gaz 6000 W WBN 6000-24 C heating boiler at your disposal, you should familiarize yourself with the information printed on the box. Here we will see a tag on which it is written that it is made in Russia and is powered by natural gas with a nominal pressure of 13 mbar. The name of the model and the heat output of the equipment are also indicated on the tag. Currently, the equipment is manufactured at a plant in the city of Engels, Saratov Region. The boiler comes in very good packaging, which prevents possible damage to the equipment.

Today, according to the BOSCH company, a huge amount of equipment imported illegally from the territory of Ukraine has been recorded on the Russian market. The cost of such equipment is relatively lower (from 24 to 26 thousand rubles) due to the complete absence of a guarantee from the manufacturer. Outwardly, this boiler is no different, but the serial number of the product does not break through the BOSCH base

![]()

Opening the box with the boiler, we find a set of documentation for the installation and connection of equipment. Everything is painted in as much detail and clearly as possible, which will help avoid confusion and mistakes during boiler installation. In addition to the data sheet and installation and maintenance instructions, there is a user manual inside. In order to protect the equipment from damage during transportation, it is clothed in foam that surrounds the device from all sides at once.

The scope of delivery includes a template to facilitate the installation of the boiler on the wall.

Instruction manual for consumers and Technical passport and instruction for installation and maintenance for a specialist in Russian, previously there was an instruction in Ukrainian.

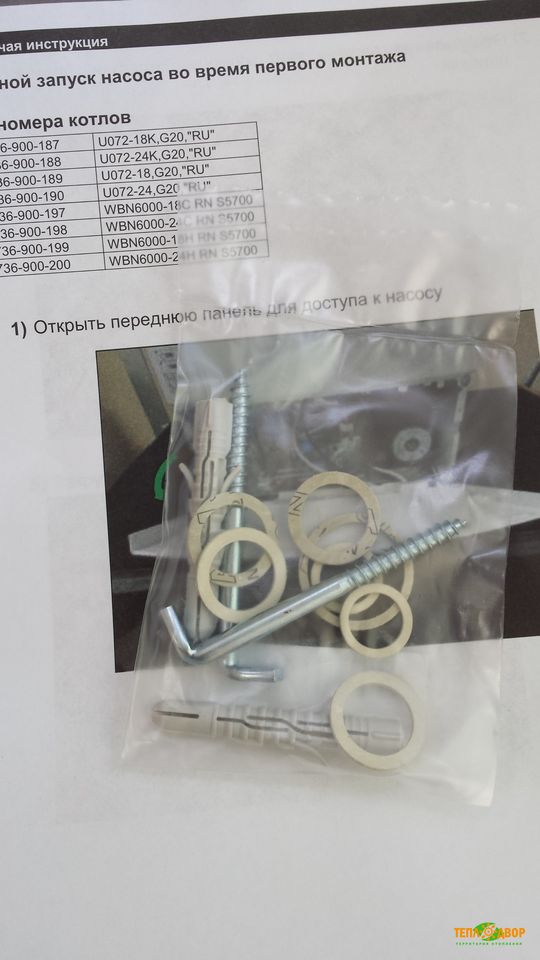

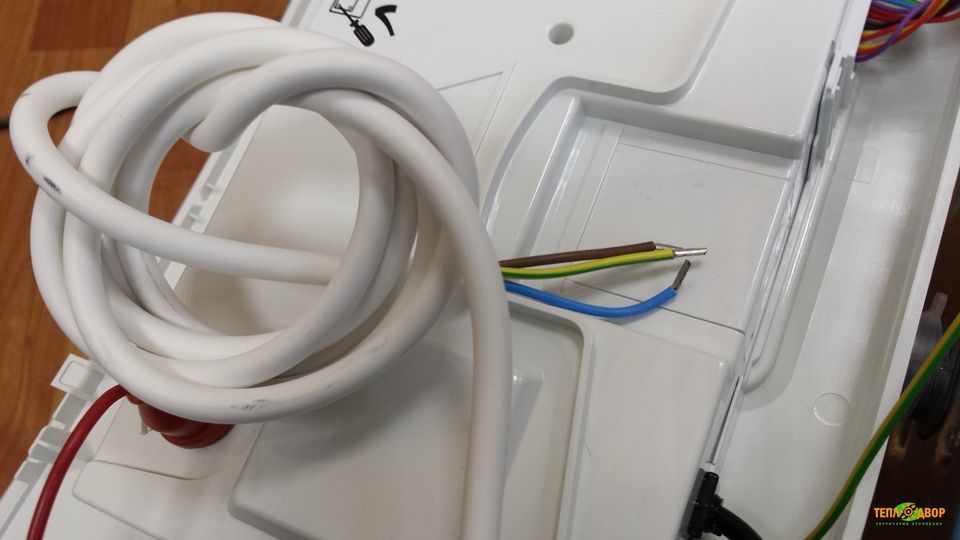

A set of gaskets for the heating and hot water circuit, a set of dowel brackets.

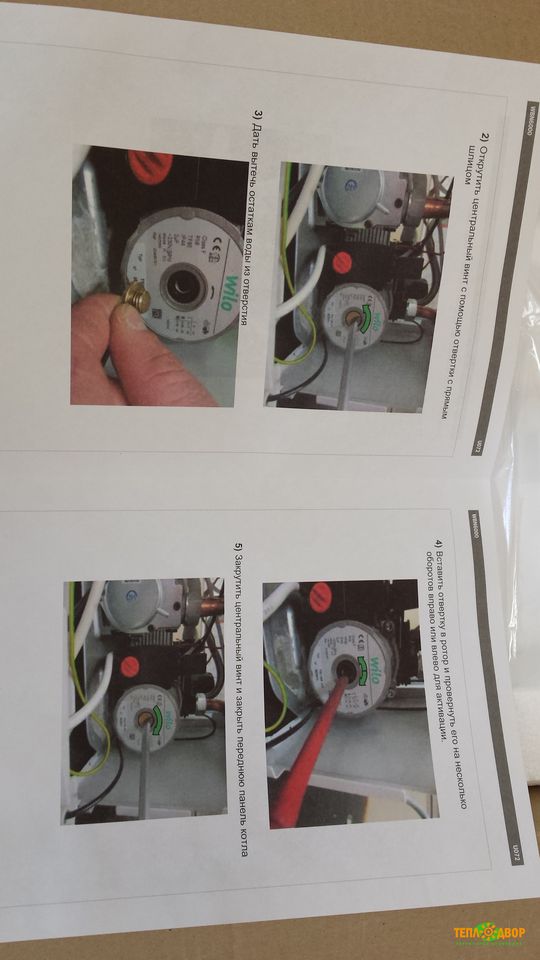

Instructions for starting the pump during initial installation.

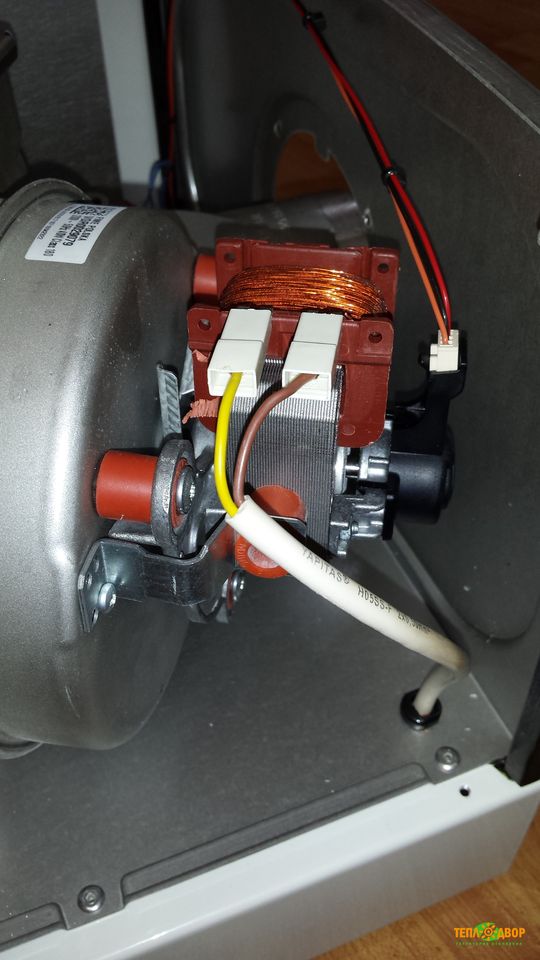

The Bosch Gaz 6000 W WBN 6000-24 C boiler is designed for wall mounting and connection to a coaxial chimney. It features flame control, automatic ignition of the burner, electronic protection and an adjustable fan. Also inside we will find a three-stage pump and a built-in expansion tank.

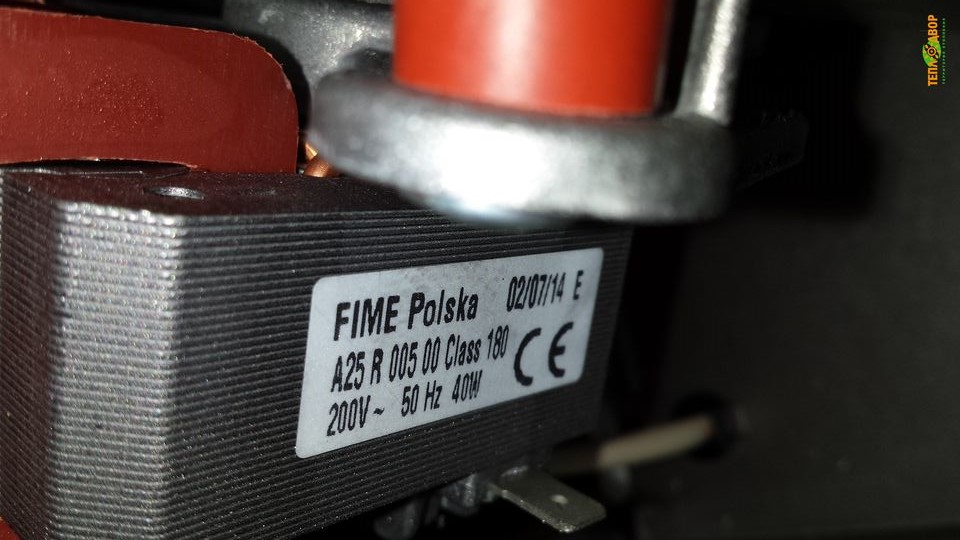

The fan, as for many other boilers, is produced in Poland, at the FIME plant

Thus, the boiler is delivered completely ready for installation.

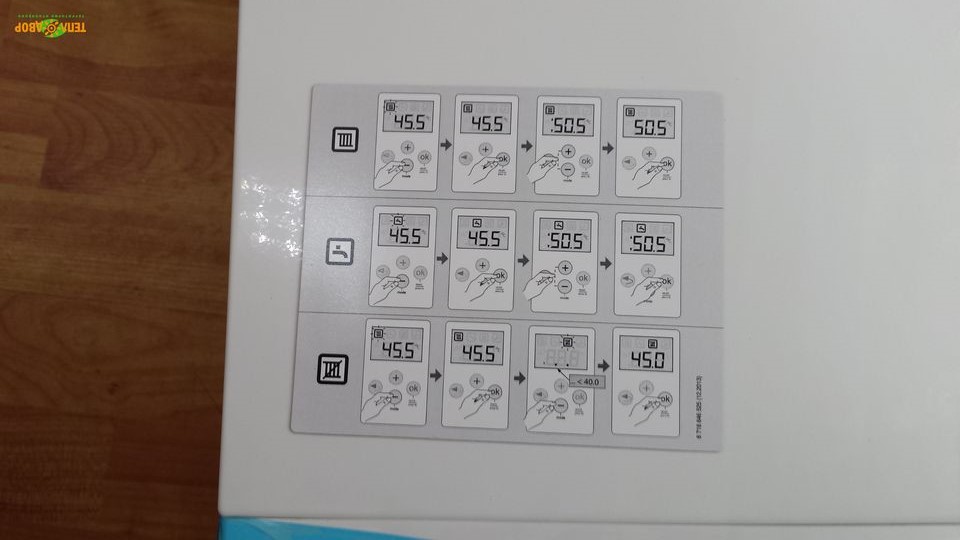

Under the foam lies the Bosch Gaz 6000 W WBN 6000-24 C boiler itself, the body of which has the correct rectangular shape... On its front panel there is a control panel with a liquid crystal display and buttons, a pressure gauge, the Bosch logo and a short graphic instruction for setting the temperature in the heating and hot water circuits.

In the lower left corner there is another tag with the name of the model and its serial number - so it is easier to look for it during warranty service or during repair work.

In order to protect the control panel from accidental scratches and roughness, it is covered with a blue technological film - after installation, they are removed.

The control panel itself is removable, behind it is access to the internal equipment of the double-circuit boiler.

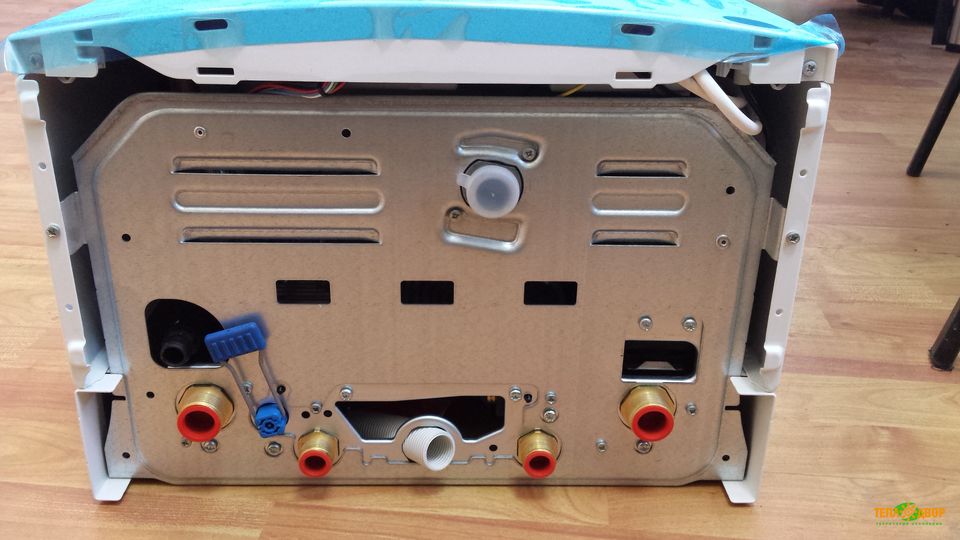

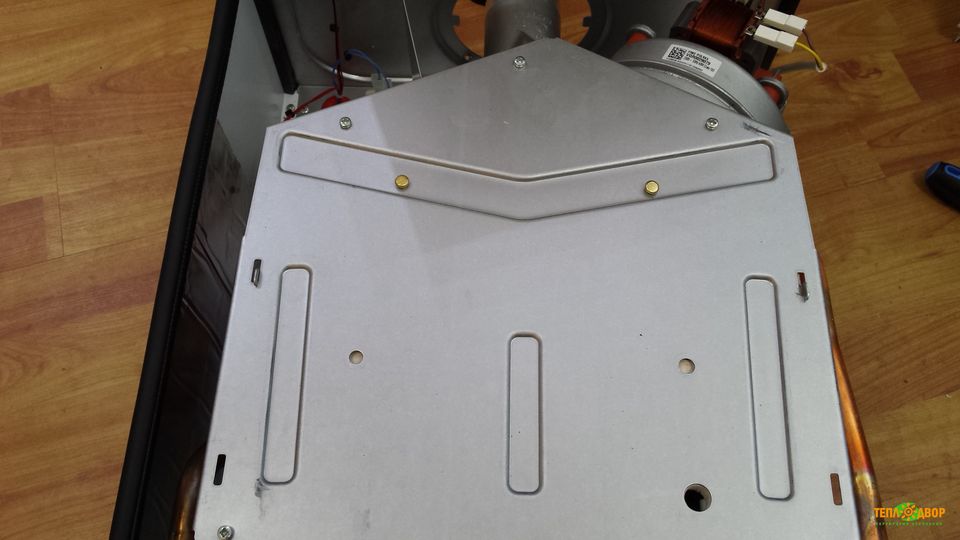

After putting the boiler down, we will find pipes for connecting elements of the water supply and heating system, a make-up valve and a discharge pipe. Their purpose is indicated in the accompanying documentation.

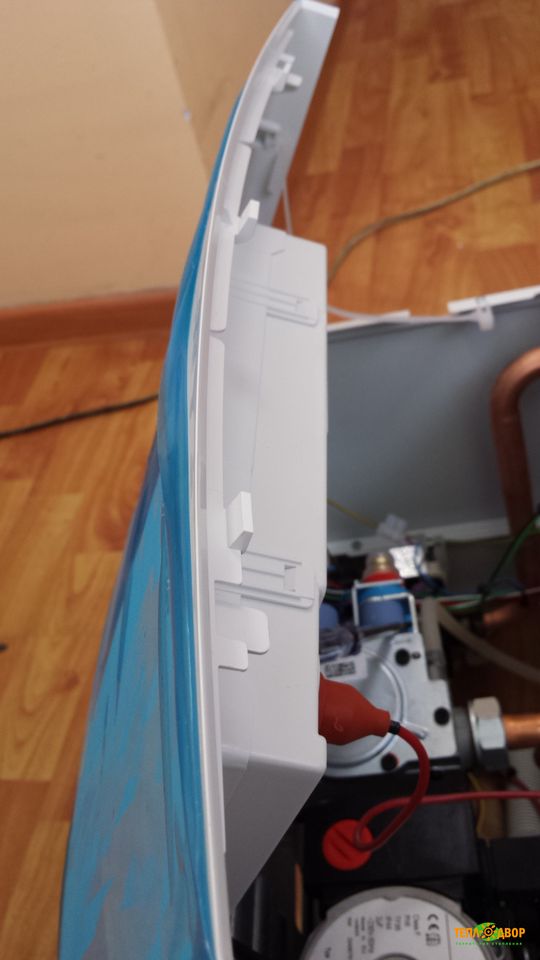

To access the internal equipment, lower the cover with the control panel down and fold it towards you. The cover will not come off and will not hang - it is held in place by plastic restraints, similar to clamps.

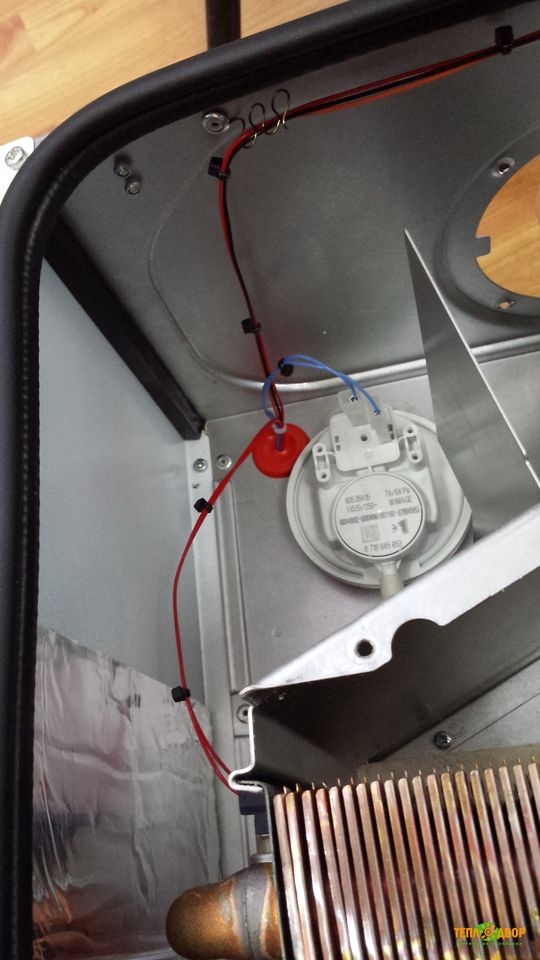

If necessary, they can be removed by unscrewing the retaining screws. In order to gain access to the combustion chamber, burner, blower fan and various sensors, you need to completely remove the metal front panel - for this we unscrew the next two screws and remove the cover to the side.

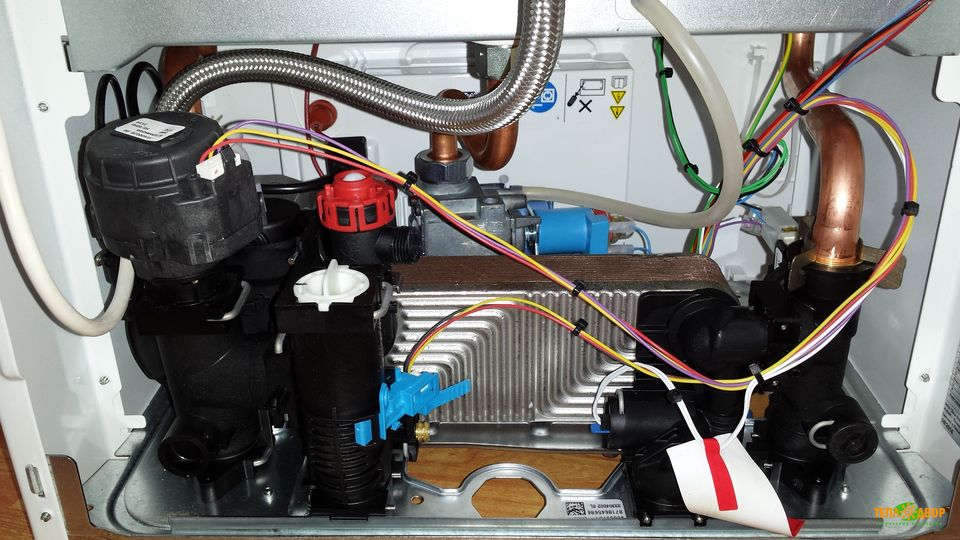

Now all the internal equipment of the boiler is ready for inspection and adjustment (or for maintenance).

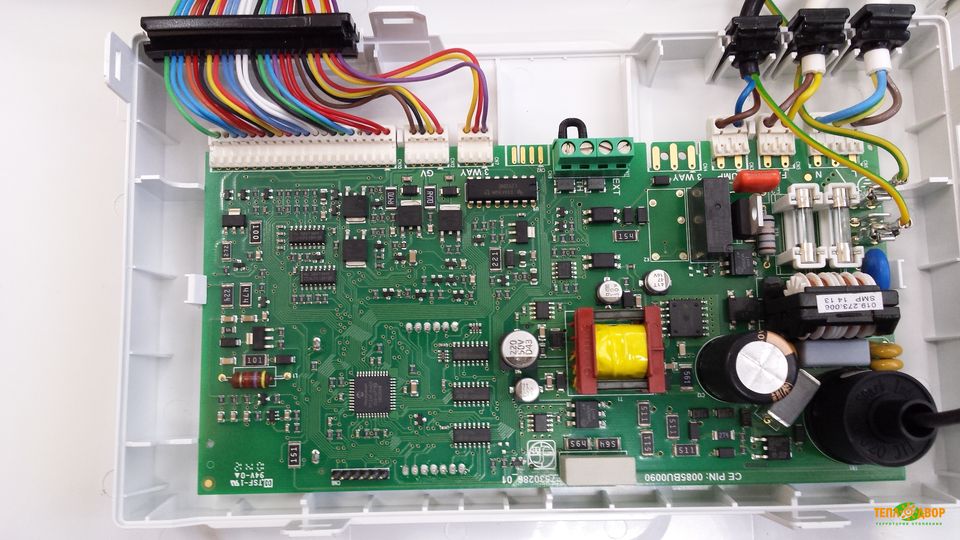

The control module of the Bosch Gaz 6000 W WBN 6000-24 C boiler is located on a hinged cover and closed with a plastic casing with warning signs. Multi-colored wires and cables go inside. You can familiarize yourself with their purpose using the proposed instructions. The plastic cover is held on the simplest latches and can be removed without much difficulty. Inside we see a fused control board. By the way, if the fuses have become unusable, they can be quickly replaced - on the inside of the cover we will see two holders in which the spare fuses are held.

To connect diagnostic equipment, an outside temperature sensor and a regulator, there is no need to remove the cover from the control module - it is enough to remove the small plastic cover, behind which the necessary connectors are hidden.

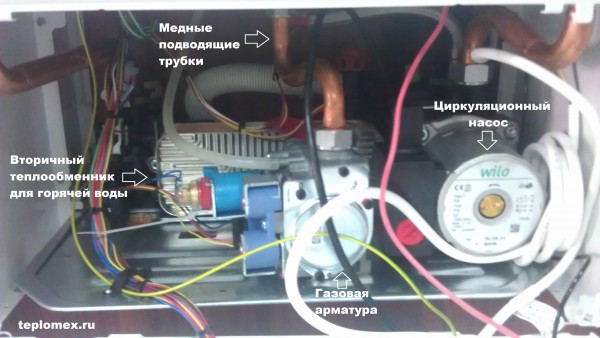

The wall-mounted double-circuit boiler Bosch Gaz 6000 W WBN 6000-24 C is easy to repair, and all its modules are located so as to provide free access to them. For example, removing the plastic cover with the control panel, we find a circulation pump with a speed switch, gas fittings, a plate heat exchanger for the DHW circuit, numerous sensors and connecting wires. Removing the front metal, we find the combustion chamber, pressure switch, exhaust pipe. For easier access to internal equipment, we can remove the side covers.

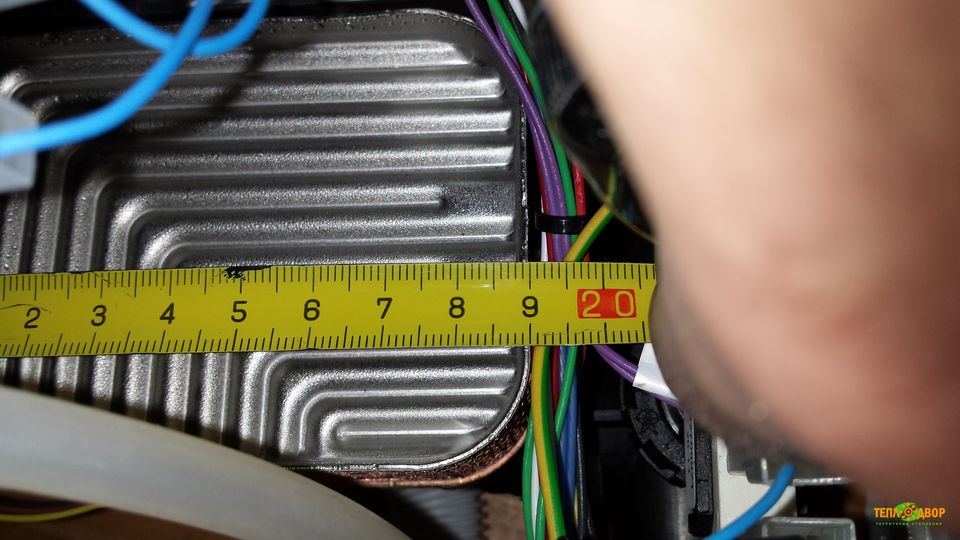

By unscrewing the front cover of the combustion chamber, we find a powerful primary copper heat exchanger and a steel burner with an ignition system. The combustion chamber itself is closed on all sides with sheets of asbestos. The heat exchanger is 37 mm thick, 152 mm wide and 267 mm long. A flat expansion tank is located behind the combustion chamber, which at first glance is completely invisible. As for the heat exchanger of the DHW circuit, it is located in the lower part of the boiler, behind the gas fittings. The hot water temperature sensor, filter and flow meter are visible next to it. To retain heat, we see thermal insulation on the case covers.

- General information about the boiler;

- Flue gas removal;

- Boiler installation;

- Electrical connections;

- Commissioning;

- Thermal disinfection.

It also tells about the process of reconfiguring the Bosch Gaz 6000 W WBN 6000-24 C boiler to a different type of gas - it can work not only from the gas main, but also from cylinders with liquefied gas. Equally important sections of the manual are "Inspection / Maintenance" and "Faults". With their help, you can understand the process of equipment maintenance and with self-help solutions for many faults.

It also tells about the process of reconfiguring the Bosch Gaz 6000 W WBN 6000-24 C boiler to a different type of gas - it can work not only from the gas main, but also from cylinders with liquefied gas. Equally important sections of the manual are "Inspection / Maintenance" and "Faults". With their help, you can understand the process of equipment maintenance and with self-help solutions for many faults.

Wall-mounted heating boilers Bosch Gaz 6000 W WBN 6000-24 C are adapted to Russian operating conditions and are extremely simple. Control is carried out using several buttons, and in order to understand the operating modes, there is an informative liquid crystal display. It will also help you get diagnostic information - if any failures occur, an error code appears on the screen. All types of faults and their codes are described in the boiler documentation.

Bosch Gaz 6000 W WBN 6000-24 C boilers are economical and can operate at reduced gas pressure. The pressure spread can be varied from 9 to 17 mbar. The supply voltage range is from 165 to 240 volts, which is quite enough for domestic power grids. Despite their good equipment, the boilers are small in size, which can be seen in the photographs presented in the review. Also, consumers will be pleased with the low noise level generated by the equipment during operation.

This view provides an overview of all boilers in the Bosch WBN 6000 range.

Setting the parameters of the 1st service level:

Setting the parameters of the 2nd and 3rd service level:

Possible malfunctions of Bosch WBN 6000-24C series boilers

__________________

Boiler repair Bosch

Using the gas boiler Bosch WBN 6000-24 C, please tell me about the hot water supply. Is it comfortable? What is the delay in filing? Doesn't scald with boiling water in the first seconds? And if, while taking a shower, the tap in the kitchen opens, does it keep the temperature stable?

If, before turning on the DHW, the boiler worked on CO, the first 20 seconds is very hot. If standing, delay up to 1 min until the temperature stabilizes. Taking a shower alone, provided that no one else turns on hot water, is comfortable. Under other conditions, temperature fluctuations are inevitable.

I cannot understand the reason why the Bosch 6000 double-circuit stopped clocking. It picks up the temperature indicated to it and keeps it constant. At the same time, sometimes, often at temperatures over 65 °, something "hisses" in it for several seconds, as if air were being thrown off.

I have the same. But my unit is 5 years old. I have dialed 60 and have been working at the minimum for a long time (ideal for wall users). At maximum speed, it hisses (on hot water), as if the heat exchanger is boiling. I will wash it out in the summer if she lives.

Need a gas boiler: single-circuit, wall-mounted, 24 kW, closed burner, with the possibility of cascade connection, tell me the Bosch model?

Bosch has only GAZ 7000 and the condensers are assembled into a cascade. In fact, if desired, any model can be assembled to work in a cascade. Units with this capability integrated into their brains can initially operate in a cascade without any additional gadgets. For the rest, you will have to buy an "extension", additional brains. Cascade controllers are named. The 7000 automatics support a cascade, but without a cascade ICM will not work. Like models from other manufacturers, which can be assembled in a cascade, additional modules are required.

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

Call a specialist to register the parameters in the service menu. Well, or try to unplug it and turn it on, maybe it will be determined by itself.

At the entrance to the Bosch Gaz 4000 W ZWA 24-2 A boiler, the DHW water consumption is 10 l / m. Outlet 2l / m. Where does it go? When the heating is switched on, the DHW heats up. One cannot be with the other, how is that related?

Bithermal heat exchanger, water heating when heating is on is logical. Start by checking the filter in front of the flow sensor - it happens that helps. If not, then flush the heat exchanger.

Error EA on the display of the bosch 6000 boiler. The flame lights up on all lamellas, but the unit stubbornly does not see the flame. In the settings, the ionization current is 0. Only the complete removal of voltage from it helps. It is noticed that the error pops up only when the temperature overboard drops below 0. At positive temperatures, this never happened (not counting the cases when the burner did not actually light up). I will try, according to your advice, to change the fan stage to 5. But I do not see any connection between the stage and the failure of the board (firmware). On firmware version 245.05, they say there is no such glitch. I would also find the firmware itself, I have programmers.

It was corrected for me as follows: I was advised to turn the plug in the socket upside down, as they explained - the position is fundamental for the boiler automation, at first I tried to turn the plug in the stabilizer - it did not help, then I turned the stabilizer plug in the mains socket. The device has been working without turning off for more than a week.

Tell me, boiler bosch gaz 4000 w zwa24-2a. Is it possible to connect automation to it so that the temperature itself is comfortable in the house?

Can. Any, with dry contact (no voltage) - for gas units.

I bought a Bosch-6000 boiler for 12 kW for my dacha, connected it to a gas holder. Accordingly, the gas is propane-butane. Household appliances have never had to be started before. Installed nozzles for liquefied gas. I switched the gas type in the boiler setting. The fan stage is set to 3. Coaxial chimney, length 2m 40cm. Gas inlet pressure 30 mbar. When trying to start, the gas pressure does not drop, it remains normal.

The boiler does not start. When you try to start the spark hits, the fire ignites, but then some valve clicks and the fire goes out. There are several exactly the same startup attempts. And the EA error appears - no flame detected. He blew air from the main several times, followed all the points of the instructions. What could be, where to look? By the way, how does this unit determine if there is a flame or not? There seems to be no optical sensor, at least I did not find it.

The unit detects the presence of a flame by an ionization electrode, which, when heated by the burner flame, generates a small current. As you were told by the ionization current. The first step would be to check the wire contact on this electrode and on the board. The second thing is how the electrode itself is installed, whether the flame hits it during ignition. And the third option, adjusting the burner with adjusting screws. Tighten the screw to increase the minimum flame. It may be that the boiler switches to minimum combustion immediately after firing up and simply goes out from the fact that the flame is very small. If it turns out to ignite, then it will be possible to adjust it to the required pressure according to the instructions.

Error C4 got out, dismantled the boiler, fixed the error, but several questions arose.

1) Perhaps the blower fan is not completely screwed on, should it be so?

2) The tubes from the differential relay go to the top of the plate, and I have it under it. What's the best and the best?

3) When the unit is started, the passport says that the fan stage must be set to 12, and the gasman said so. And I have 5 in the instructions, although they are the same, how is it right and better?

If you flush the filter, it should work.

Can you please tell me where to buy the 94/74 pressostat for ZWA? The device is cut down constantly by a pressure switch error. I blew it, cleaned it, checked the pipe twice. It seems to work. 5 days ago it turned off again. Ice on the pipe. He insulated the pipe and changed the slope. No naled since then. The condensate all flies out. Yesterday I started to turn off again. It works stably only in 4th gear, when the heating is constantly boiling. If you decrease it, then after several measures it goes out again with the same error. I conclude that this is a relay.

Condensation may have got on the contacts.

As I understand it, with a double-circuit boiler, you can not bring cold water to the shower at all, but regulate the temperature by pressure. Bosch 24 (in my case) gives out the temperature, with the hot water tap fully open, no more than 28 grams (supply 25 pp, outlets 20). Is that how it should be?

The unit must keep the set temperature if the flow rate is in the range of 2.5 -11 l / min. With a fully open tap, the flow rate can be higher, therefore it cannot heat.

Tell me, can you connect a BKN to a dual-circuit Bosch 6000 or only to a single-circuit one? And what are the features of the connection, we put a three-way valve for heating, it is controlled from the boiler sensor. And how to let the unit know so that when switching to the boiler it would give out all the power and, most importantly, what to do with the DHW circuit, turn it off or need to connect it somewhere?

Technically possible. The main thing is just the first, letting the boiler know about switching to DHW can only be through the flow sensor, but there are not simple contacts, but a Hall sensor, and you need to somehow simulate the flow. The flow sensor is on the hot water supply, and the boiler will be connected to the heating circuit through a three-way valve, like a single-circuit one. You just need to give the device a command to give out all the power. He receives this command through the DHW flow sensor.

How often does a turbocharged boiler turn on? It costs me 50g, heats up to 54, then cools down to 46 and starts up again within 20 minutes.

Put a room thermostat, then it will turn on according to the room temperature, and not according to the temperature of the coolant. Without a thermostat, of course, it will turn on more often.

My boiler temperature is set to 50g. It heats up to 54, then stops heating and the fan turns on and cools down to 50 -49 gr. Is that how it should be or not?

This is normal, only this is not a fan, but a pump inside it, which drives the coolant through the heating system. And the coolant cools down in your heating radiators and warm floors. The pump overrun time is set in the service menu of the unit.

Tell me if this is normal - the indicators of the heating system and summer mode are simultaneously lit on the display. Boiler Bosch WBN 6000 24H RN. Installed by the master from asts, 2 weeks ago. Both icons are on from that moment on - I thought it should be so.

The mode in the frame is active, that is, at the moment - heating.

It seems to me that protection should be precisely the presence of coolant circulation. Regardless of whether there is gas or errors in the boiler. Right?

No. The unit must be switched on and without errors. It can stand in standby mode, and it turns on itself when the temperature drops below 5 degrees, heats up to 40 degrees, and so on.

I heard that the BKN crashes into the heating system through a three-way external valve or a loading pump, or both. They are controlled by the BKN automatics. What is BKN automation? What will control the loading pump and bring the burner to maximum?

BKN is a boiler indirect heating... BKN automatics - boiler thermoregulation automatics. It is connected to 220V. It has a thermal relay to turn on the pump and drive a three-way valve, as well as depending on the heating element modification. Naturally, the boiler will give out the temperature that is set for heating. This will just slightly increase the heating time of the boiler.

Can someone explain the point of the instruction: Set the pre-pressure in the expansion vessel in accordance with the static height of the heating system. How to understand how to set the pressure in the tank? Or leave the factory?

If the house, for example, has 3 floors, the expansion tank is on the first, the height difference between the upper point of the CO and RB is 7m, then the static pressure is 0.7 atm. We pump the expansion tank by 0.3-0.5 atm. more than static pressure. If the system is all at the same level, then 0.5-0.7 in RB is enough.

Question about the circulation pump on the Bosch WBN-6000 single-circuit. In my opinion, it hums too much and there is a slight vibration. Vibration and hum are not very strong and come from the circulation pump, and not from the turbine. At the same time, another pump for circulation of the BKN heated towel rail works nearby, which works absolutely without noise and vibration. I think there is something wrong with the pump. But it makes no sense to call someone, because for sure the noise is within the passport standards and the water circulates normally. But the noise is annoying. In this regard, what do I think to do: In order not to disassemble anything and not to lose the warranty, put your pump at the exit from the boiler, take power from your own pump. And just disconnect the native.

The only thing that worries: I read somewhere that the boiler pumps have a small "snail" and that these pumps in the off state give much greater resistance to flow than a conventional pump. Is this true for the WBN-6000 pump? A conventional pump, in theory, is normally pressed through. Does anyone have any information?

Try to vent the air from the pump. Unscrew the central screw.

Can you please tell me if the WBN 6000 single-circuit has a DHW priority over heating, if so how. I did not find it in the "engineering" menu. And what is the priority set from the factory.

Priority from factory to DHW. Most likely, it does not change. Yes, it is not necessary. The 120 liter tank heats up in minutes.

I ask you to advise on the Bosch Gaz 4000 ZWA 24-2A-23 double-circuit boiler. I am considering this bithermal apparatus to replace another 2-circuit one with a plate heat exchanger. In this connection, the questions arose:

1. The instructions say that it is forbidden to use with thermostatic regulators on radiators. I once have such, but connected to a one-pipe system. How critical is it if you unscrew the adjusting knobs to the maximum?

2. The CO is constructed in such a way that water is constantly pumped through the boiler by external pumps. That is, when it operates on hot water supply, part of the heat will go to CO, right? Can it so happen that the required temperature will never be obtained in the DHW?

3. The instructions say that the priority is set to DHW. How is it physically implemented in such models - when a flow occurs in the hot water supply, the burner gives less heat?

4. Now the BKN is connected to the DHW outlet of the boiler with a circulation pump switched on from the temperature sensor on the BKN. Will ZWA work in the same configuration? The reason for the replacement is that the temperature drop is not satisfied when the DHW circuit is turned on, that is, the heating of the BKN. Electric power is only 5 kW, so I don't count on it.

It will be the same. The burner produces more heat. DHW priority means switching to DHW mode when the flow sensor is triggered, regardless of the current state, heating or standby.

Malfunction of the Bosch 6000-24 boiler. Installed and connected at the end of October 2014. That is, it has been in operation for 5 months and from the very beginning, as the temperature outside below 0 began to drop, we have problems with it. Initially, it gave an Err Error - at the set degrees 50-55. As they started to put 65, the problem disappeared (of course it was hot, but I opened the windows). That is, the flame was blown out due to the fact that it was not high. Now frosts have come, it reaches -25 at night and once a day by the morning at such temperatures, the boiler issues C4 errors first, the next day C6. I called the gas workers. They stated that it is freezing due to the fact that it was developed by Europeans and is not adapted to such frosts and winds. There are no solutions, except perhaps

remove the gasket in the coaxial pipe at the junction of the elbow and the pipe so that it partially draws warm air from the room. But I think that this will not solve the problem, but will only add another source of draft to us, of which we have enough due to the lack of window sills and slopes.

Errors C4 and C6 indicate differential pressure switch and fan, have the repairers checked this?

"The boiler is freezing" - this is not a very serious conclusion.

C4 - Differential pressure switch does not open when the fan is off.

Check differential pressure switch.

C6 - Differential pressure switch does not close.

Check the fan and its cable with a plug, replace if necessary.

Check differential pressure switch and flue gas pipes.

Is the fan stage set correctly?

If the differential relay is working properly, then condensation in the chimney may be preventing its normal operation. That is, you need to try to eliminate condensation (from simple insulation of the chimney with mineral wool to the installation of a condensate drainage system). And I would also try to increase the temperature of the coolant to at least 75 degrees (especially, severe frosts) and connect a simple relay thermostat to the device so that there are no tropics in the house. If you could get to the differential relay, then remove the jumper on the control unit and connect a thermostat instead, then you can do it.

The situation is as follows: a couple of days ago, I finally connected the gas and a representative of the gas company started the boiler. When starting up, he measured the grounding and said that it was not very good, 220/130, if I'm not mistaken (I don't understand electrics). So, as a result, the boiler gives out an EA error about 7-10 hours after starting, and does not turn on by resetting the error. And you can hear how the flame lights up, you can see how the temperature rises by 10-15 degrees, but the flame icon does not appear, so it tries to start up three times, then again gives an EA error. It can only be started by pulling the plug out of the socket and plugging it back in. Gas workers say to do normal grounding. The question is: is it really

is it related to grounding? Or do you need to look in a different direction?

Grounding, most likely nothing to do with it. Although the opinion of the gas industry is reasonable, since this error is related to the operation of the board. My boiler without grounding gave this error and so it works fine without grounding. So far, there is only one solution - to reflash the board (in Bosch services they are well aware of this error). Or set the degree of fan operation to 5. It is easy to do it yourself through the menu. The solution came by chance, since the cause of the error is not fully understood, but the truth is, this way of solving the problem has not yet been refuted.

Malfunction of a gas turbocharged boiler Bosch Gaz 6000 W-12 often an EA error occurs - No flame detected. The unit turns on and runs without problems. I worked at 75 degrees all winter and gave this error only three times. With warming, I set it to 45 degrees and the error began to pop up every day and sometimes 2 times a day. In general, up to 50 degrees, the error often highlights, over 50 degrees is rare. Before giving an error, the flame icon disappears. He tries to start again, makes the first attempt (unsuccessfully), then the second attempt to ignite, and so on 5 times and then issues a blocking error EA. When you try to ignite, you can actually hear how the gas flashes and goes out and there is no icon (flame). I reset the error by holding the OK button, the icon (flame) does not appear and it again makes 5 ignition attempts. I fix this problem like this - I reset the error and turn it off for 5 seconds, then turn it on, and everything works and the icon (flame) is present. But how long it will work without giving out errors, you can't guess. At low temperatures, it can give an error in an hour, or it can work normally for two days. Well, as I wrote above that at over 50 degrees, an error rarely occurs.

1) Gas pressure.

2) If the gas pressure is normal, try swapping the wires (ionization electrode and ignition electrode), sometimes it helps.

3) If not, then change the board, or reflash.

With a similar error, EA adjusted it by increasing the fan stage from 2 to 5 (In the service menu). I think the error was due to the fact that the fan did not have time to provide the device with fresh air, so it went out without air. The chimney in my wall is like 0.7 meters long. The channel is not narrowed by any gaskets, but it is slightly narrowed by the clamp of the joint between the corner element and the straight pipe, since its design is very strange.

The wall-mounted boiler Bosch Gaz 6000 is in operation. It worked for a couple of months in summer mode. Turned on the heating - it works, but the temperature of the coolant is not adjusted above 50 degrees. But the most interesting (bad) thing is that it does not allow you to enter the service menu. At the same time pressing + and - does not react in any way. Who knows what to do?

You press the plus or minus and the cancel arrow. You are waiting.

Malfunction of the Bosch 24 boiler (2-circuit). Periodically gives an error EA - does not see the burner. What is the problem?

The gas mixture is not supplied at the correct volume or pressure. EA error is solved by fan speed (step), minimum gas supply, rarely by replacing the control board.

There are still questions about setting and adjusting the boiler. During commissioning, the service technician did not check the pressure on the injectors and, of course, did not set it. So the question is: having reduced the power in the parameters - have I reduced the pressure on the nozzles or what? Is the device delivered from the factory not configured according to the table in the instructions? Or should the pressure be set to the required maximum power for each house?

1. By decreasing the power, you decrease the gas pressure on the injectors. But it is better to do it with a pressure gauge.

2. The boiler is factory set at mains pressure, if the memory does not change 13 mbar. If you have more, then the pressure on the injectors will be higher, so you need to check it during commissioning.

Gas boiler Bosch 6000 is in operation. Malfunction in the control board. Saves the parameters for heating. We set the temperature to 55 degrees. Since it became warm outside. Reduce the temperature by 40 degrees. The next day, the temperature of the coolant is also 55. Having set the temperature to 40 degrees, I turn off the power to the device, turn it on and again the temperature of the coolant is 55 degrees. Having also turned on the summer mode, after turning off the power, it turns on in heating. I reset the settings to the factory settings. Did not help.

Parameter 2.9A is set to value "2", but should be "0". The second level of the service menu L2.

Changed the control board on the bosch wbn 6000-24c boiler. After switching on, the boiler gives an error "P" - "The type of boiler is not defined". To determine the type, use the service function 3.1.a. When calling the function, one of the presented values \u200b\u200bcan be selected: 0, 20, 21, 30, 31, 32, 40, 41, 42, 50, 51, 52. Tell me, if anyone has come across, what value should be set for this model.

For this modification of the unit, the parameter value must be 31.

_______________________________________________________________________________

_______________________________________________________________________________

____________________________________________________________________________

_____________________________________________________________

_____________________________________________________________

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

Features. Installation and assembly. Automation components.

Technical specifications. Installation. Adjustment and check. Maintenance.

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but it gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW device?

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for a three-way valve malfunction (there are no leaks from the radiators)?

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed, etc. Is it possible to really reduce the power?

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation of turboTEC plus VU / 5-5 compared to / 3-5?

Malfunction in the operation of the boiler, the green LED (power supply) is flashing, the instructions say that the thermal protection has worked, the green indicator is flashing, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

Installed and connected wall-mounted boiler Electrolux Basic Xi. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

Malfunction of the Koreastar boiler. Heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No regularity is revealed. What to do?

Bosch has gained a worldwide reputation for producing quality home appliances for many years. AT last years it expanded its product segment by launching household products in Portugal and Russia gas equipment for heating and water supply at home.

Wall mounted gas boilers Bosch rather quickly took their place in the market, primarily due to their well-known brand, quality and reliability, and at the same time - a low price for products.

I propose to make an overview of the boilers of this world-famous brand together, focusing on the model range, internal structure, functionality, technical characteristics of equipment, and show the advantages and disadvantages of Bosch boilers using this review as an example.

Bosch gas boiler models

In Russia and throughout the post-Soviet space, we can find several types of wall-mounted gas boilers from a German company. Let's see what features they have.

The boilers are manufactured in two versions:

- double-circuit gas boilers

- single-circuit gas boilers with the ability to connect an indirect water heating boiler

Gas boiler Bosch Gaz 6000

1. Double-circuit boilers Bosch are produced in 12, 18 and 24 kW. These boiler models are marked Bosch Gaz WBN 6000-24 C, the number 24 or 12.18 indicates the power of this model, and the letter "C" indicates that this boiler has two water circuits, i.e. designed for heating and hot water supply according to the flow principle.

It is advisable to buy a capacity of at least 24 kW, because models with a lower capacity produce hot running water only 8 liters per minute. In practice, it is known that this capacity is not enough for the full operation of the DHW circuit. A device with a nominal power of 24 kW will give us 11-12 l / min.

2. Bosch single-circuit gas boilers can also be found with a capacity of 12 to 24 kW. This model is designated Bosch Gaz WBN 6000-24 H... Where the “H” symbol indicates that this type of boiler has the ability to connect an indirect heating boiler to it.

The volume of the boiler can be different: 100, 150, 200 liters, it already depends on your needs and the number of people who will use hot water for household needs.

All models of gas boilers are equipped with a turbine for exhausting flue gases. Due to this turbine, forced draft is carried out, which does not require the installation of a chimney in the house.

It is enough to buy a boiler, which consists of two pipes. Through a pipe of a smaller diameter, combustion products are emitted, through a pipe of a larger diameter, the flow of air from the atmosphere into the gas boiler.

The coaxial flue has a standard diameter of 60/100 mm and is installed in the wall behind the boiler or through the side wall. These pipes can be extended by purchasing separately special coaxial chimney extensions. It is also possible to install separate pipes (outlet and inflow) with a diameter of 80 mm.

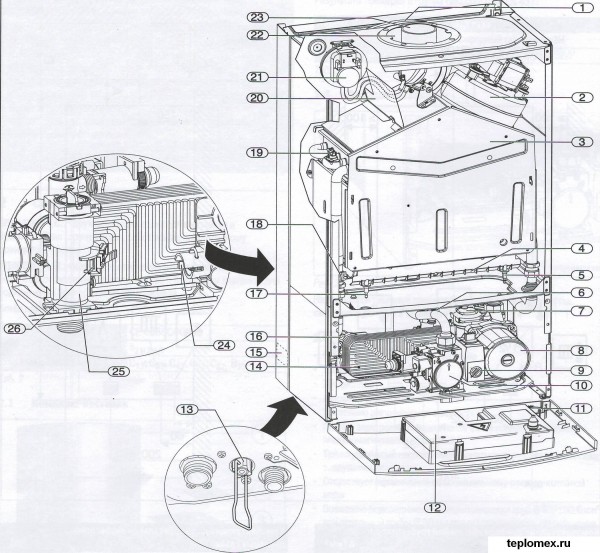

Bosch double-circuit gas boiler device

Now let's look at what a gas boiler from a German company consists of, what is "hidden" inside it under the body. Let's carefully analyze the internal structure diagram.

The device of a gas double-circuit boiler Bosch Gaz WBN 6000-24C

1 - Membrane expansion tank

2 - Turbine for exhaust of combustion products

3 - Combustion chamber

4 - Gas burner of the boiler

5 - Burner ignition electrode

6 - the Safety valve

7 - Air relief valve

8 - the Circulation pump

9 - Adjusting the pump operating mode

10 - Gas part

11 - Manometer

12 - Boiler control panel

13 - Device for powering the system

14 - Secondary heat exchanger

15 - Nameplate for boiler warranty

16 - pressure switch

17 - Ionization electrode

18 - Heating circuit temperature sensor

19 - Emergency heating circuit temperature sensor

20 - the damper for air supply

21 - Differential relay

22 - Air suction into the boiler

23 - Emission of combustion products

24 - DHW temperature sensor

25 - Filter

26 - Flow meter

Features of wall-mounted gas boilers Bosch Gaz 6000

Boilers of the WBN 6000-24C series are equipped with two heat exchangers. The primary heat exchanger heats the water in the heating circuit and is made of copper. Thanks to a small secondary heat exchanger, the running water in the hot water circuit is heated.

Bosch Gaz WBN 6000-24H single-circuit models have only one - the main copper heat exchanger for heating water in the heating system.

The hydraulic part of the boiler is made of high quality copper. The expansion tank has a volume of 8 liters, which is sufficient for classical system heating single or two-storey house with aluminum radiators and polypropylene pipes with a diameter of 25 mm.

Bosch double-circuit gas boiler device

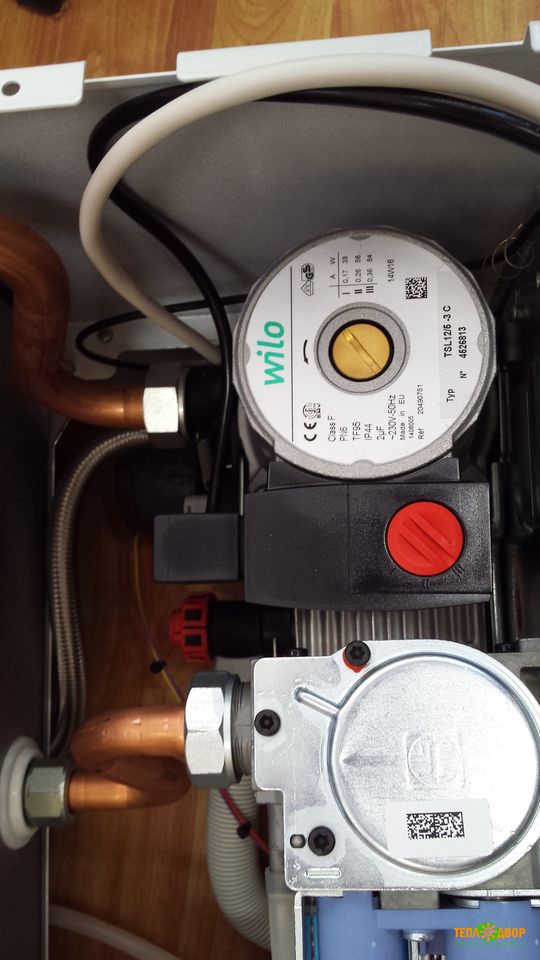

The main components of the boiler are of good quality, but they are not "native". For example, in the photo above, we can see that even the built-in circulation pump in this wall-mounted gas boiler from the well-known German company “ Wilo».

The boiler is equipped with a winter-summer system, which helps to save gas in various weather conditions. There is frost protection, pump blocking protection, gas control system, as well as weather-dependent automation.

It should be noted that the temperature is set using the buttons on the control unit only for the coolant. But there is a possibility of setting for setting a more accurate air temperature in a room or house.

You should also not forget about the purchase, which will help save the electronic board of the boiler from surges in the power grid. And also the systems "Albatross" or "Radel", which protect the boiler during thunderstorms. They are inexpensive, but they will save you from more serious problems with a wall-mounted gas boiler.

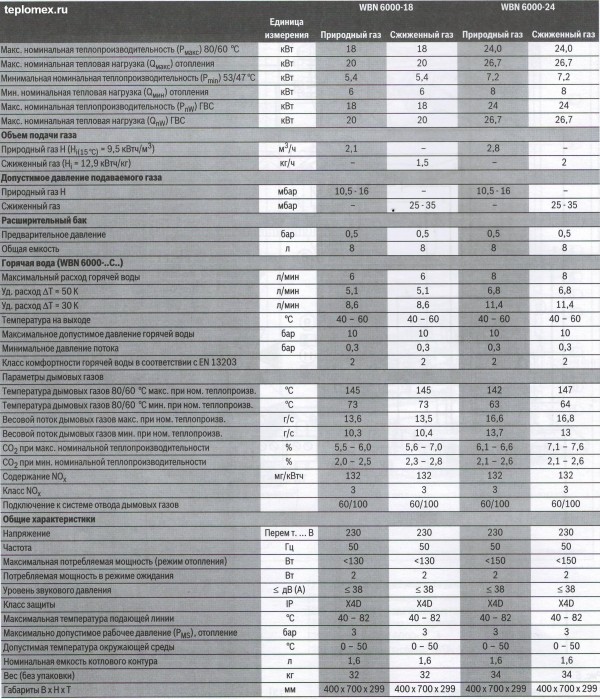

Bosch double-circuit gas boiler: specifications

Technical characteristics of Bosch gas boilers

What are the advantages of wall-mounted boilers Bosch

- quality of materials

- low noise during operation

- low price from 400 Euro

- European brand

Disadvantages of Bosch gas boilers

- the company is not a manufacturer

- not "native" spare parts

- narrow model range

- a small number of service centers

Wall-mounted gas boiler Bosch is a good "anti-crisis" option for people who prefer a well-known brand for little money. The standard set of functions and components make the boiler models of this brand quite competitive in the Russian market.

However, if you prefer, first of all, quality from the manufacturer, as well as service, then I would recommend buying a gas boiler from companies that specialize in the production of only heating equipment. They usually have better debugged service maintenance boilers and a wider range of models. Watching the video.

Today we have made a review with you on gas boilers Bosch, considered both the internal structure and its technical characteristics. Despite some of the boiler's shortcomings described above, in general, this brand is worthy of the attention of consumers, and, moreover, with different financial wealth.