Monolithic reinforced concrete base - features and construction technology. Do-it-yourself monolithic concrete foundation

A monolithic foundation in the understanding of most builders is such a foundation for a structure, which is made of solid reinforced concrete. A monolithic foundation can be piled, slab or strip. Each type of monolithic foundation is used not only in the construction of the private sector - many large objects are built on a monolithic foundation. Since a material such as reinforced concrete guarantees durability and reliability supporting structure, and the technology of a monolithic foundation is relatively simple, then the construction of such a foundation can be done on its own, without resorting to outside help.

This foundation can be applied to different soils.

To build a really high-quality and durable monolithic concrete foundation, a large amount of concrete mortar and reinforcing rods will be required, perhaps (if a block foundation is being built), FBS blocks will be needed. When the poured concrete dries, a very strong reinforced concrete mass is formed, which is not afraid of increased compressive loads. The reinforcing frame is essential part monolithic foundation, we can say that this frame is the basis of the entire supporting structure. It is due to the reinforcement that the load of the structure is evenly distributed over the entire base (as opposed to a brick foundation). Reinforcement bars respond best to compressive and tensile loads, so the reinforced frame should be placed as close to the surface of the supporting structure as possible. Even the simplest, but correctly laid reinforcement belt will give the foundation strength and reliability.

According to such a feature as the depth of laying, monolithic foundations are divided into two types:

- a deep foundation, the base of which is settled at a depth below the level of soil freezing, this type includes pile and strip foundations;

- shallow foundation (non-buried or shallow foundation) is distinguished by a shallow depth of laying of the supporting structure; as a rule, a shallow base is slab or strip.

How to make a monolithic foundation yourself

In the manufacture of a monolithic supporting structure, the most difficult stage is the calculation of the base. In the course of calculations, the following must be taken into account: the height of the future structure, the required thickness of the walls of the house, the level of soil freezing, the depth of groundwater, and, naturally, the nature of the soil. The calculation of a monolithic foundation is a very important stage, therefore it is worth approaching it with the utmost care in order to be one hundred percent confident in the foundation being built.

Competent reinforcement of the foundation, its waterproofing, as well as the correct choice of concrete mix and formwork also affect the durability and performance of the future structure. In addition, the construction estimate should include a contingency item (purchase of additional reinforcement or cement).

Parameters of the "sole" of the supporting structure

It is important here to calculate as accurately as possible the size of the area for the "sole". The type of monolithic foundation is selected based on the strength of the soil resistance and the approximate load from the future cottage (such data should be taken into account, even when building a simple gazebo):

- if the soil on the site is not subject to movement and has an average or low degree of heaving, then a strip base should be laid; this type of supporting structure is especially relevant if a monolithic foundation with a basement is being erected or a basement is provided in the house.

- provided that the soil is heaving, with a deep level of freezing, and is also subject to seasonal changes, then a monolithic foundation slab will be the best way out of the situation; a ribbed slab foundation can also be used, which is a reinforced concrete slab with stiffening ribs on the lower surface. Such a sole has a maximum area, thanks to which the load on the ground is distributed more evenly, which makes the entire structure very stable and strong. The cost of such a base is relatively low, which makes its use very attractive;

- if the soil is heaving, but the depth of its freezing is relatively small, then it is best to use a pile-grillage foundation, which must be laid below the level of soil freezing. This type of supporting structure is also justified in the event that a structure with a not too large mass is installed on a monolithic foundation for a house.

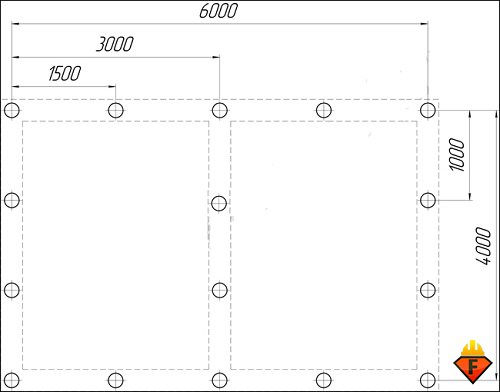

Monolithic supporting structure drawings

The simplest diagram of the device of the future monolithic foundation is drawn up independently without much work. This will require the data obtained earlier. Below you can see a drawing made according to SNiP for a slab base under wooden house 6x6 meters:

If a continuous strip foundation is being erected, then the location of the bearing walls, under which the base strip will be located, should be taken into account, and draw approximately the following scheme:

You can see the section of the monolithic concrete foundation in the following image:

Sometimes the most preferred option is a columnar foundation on bored piles. In this case, it is necessary to position the supports as correctly as possible, and in places with the greatest load, somewhat reduce the distance between the posts (in more detail about this technology, its technological map will tell you).

Preparation for construction work is very important, it is necessary to thoroughly check the soil on the site. No need to spend money on the services of professionals: with the help of an ordinary garden drill, you can check the condition of the soil in different places of your site and reveal hidden flaws. For example, too wet soil in the upper layers may indicate a high level of groundwater.

Columnar-girder monolithic foundation

Such a supporting structure is something in between a shallow foundation and a deep foundation. The columnar-girder foundation perfectly manifests itself in conditions of heaving soils, peat bogs and areas with a slope. As a rule, it is not necessary to fill the grillage on such soils, a sand and gravel cushion is sufficient.

Under ordinary conditions, such a foundation is arranged as follows. Every two meters, glass-type piles are drilled and poured along the perimeter of the supporting structure to a depth of 1.5 meters. The pile length should be 250 millimeters. It is on these piles that the monolithic foundation will rely. Often, this technology is resorted to when you need to build a foundation for a fence.

Foundation reinforcement

As already mentioned, the reinforcement frame is an indispensable part of any monolithic supporting structure. If the foundation is being built for brick house, a supporting structure is being built for a column, or you need to build a powerful foundation for a garage, then you cannot do without a reinforced frame. It is he who evenly distributes the load on the foundation. Reinforcement rods are of various types, you can read about this here.

How to choose the right concrete

The choice of the grade of concrete mix depends on the degree of load on the base. It is also worth considering the characteristics of the soil and the weather conditions in which the supporting structure will stand. Read about how to choose the right concrete for your foundation in this article.

It is not enough just to fill in a good foundation; you also need a cushion of rubble or sand, laid in a trench and tamped tightly. In addition, you will need a formwork structure that will hold the concrete solution during curing. To preserve strength and solidity, the supporting structure should also be insulated and waterproofed, and then let it stand for a couple of weeks, then the base will be erected in accordance with GOST. Such measures are especially necessary if a monolithic foundation for a bath is being built.

Pros and cons of a monolithic base

The positive qualities of a monolithic foundation are resistance to weak soils and groundwater, the possibility of replanning the supporting structure, as well as an even distribution of loads on the foundation. In addition, a monolithic foundation is not as difficult to build as other types of load-bearing structures.

Video

Monolithic foundation device

Casting a monolithic foundation

A monolithic foundation is erected as the foundation for cottages, wooden houses, farm structures

for a specific purpose. Being universal, such a foundation is ideal for the construction of buildings on heaving and uneven soils subject to compression - sandy soils, peat bogs, etc. Ground movements do not affect the stability of the building structure, which is equipped with a monolithic base. Due to its resistance to ground movements, a monolithic foundation is usually called "Floating".

Monolithic foundation price

The relative cheapness of work when arranging a monolithic foundation is one of the advantages. Its construction does not require the use of special equipment, the consumption of materials is low, the materials themselves are inexpensive and generally available. In this case, the configuration of the building can be any - the foundation design assumes a variety of geometry. According to various estimates, the construction of a monolithic foundation will cost 15-20% of the construction cost of the entire building.

Reinforced concrete monolithic foundation

The most reliable and affordable way to build a monolithic foundation is to use a reinforced concrete structure. Such a foundation takes the load of the house evenly, is not subject to extrusion and destruction, is durable, staunchly resists the effects of aggressive environments.

Structurally, the monolithic foundation is a reinforced concrete slab connected to the walls in a single whole. In the manufacture of a wire frame mesh (in two layers or more), as well as reinforcing bars. A monolithic foundation often serves as the base of a building. If a large deepening is not required, the foundation is erected without monolithic slab... Instead of a pit, in this case, a trench is dug.

Monolithic foundation construction

At the bottom of the pit, a sand cushion is arranged, formwork is being built, a reinforcing cage is laid, and a concrete slab is poured. The reinforcement should protrude from the surface of the slab for subsequent bonding to the walls. After the concrete slab has hardened, the frame is mounted, the wall formwork is installed. Reinforcing bars are used at a distance of 30 cm from each other. The diameter of the rods is 12-14 mm. Dismantling of the formwork begins when the concrete has hardened.

When building a foundation without reinforced concrete slab the technology is the same. Concrete is poured into the formwork with a reinforcing cage and allowed to harden, the formwork is dismantled.

During the construction process, it is important to carry out drainage and waterproofing work.

The cost of a monolithic foundation

We work in all districts of Moscow and Moscow region:

Aprelevka, Balashikha, Bronnitsy, Vereya, Vidnoe, Vlasikha, Volokolamsk, Voskresensk, Vysokovsk, Golitsyno, Dedovsk, Dzerzhinsky, Dmitrov, Dolgoprudny, Domodedovo, Drezna, Dubna, Yegoryevsk, Zheleznodorozhny, Zhukovsky, Zaraysk, Zvenikorod, Ivkistra, Ivk Kashira, Klimovsk, Klin, Kolomna, Korolev, Kotelniki, Kraskovo, Krasnoarmeysk, Krasnogorsk, Krasnozavodsk, Krasnoznamensk, Kubinka, Kurovskoe, Likino-Dulyovo, Lobnya, Lukhovitsy, Lytkarino, Lyubertsy, Malakhovka, Mozhaisk-, Mytiino Fominsk, Nakhabino, Noginsk, Odintsovo, Necklace, Lakes, Orekhovo-Zuevo, Pavlovsky Posad, Peresvet, Podolsk, Protvino, Pushkino, Pushchino, Ramenskoye, Reutov, Roshal, Ruza, Sergiev Posad, Serpukhov, Solnechnogorsk, Staraya Kupavnahod , Taldom, Tomilino, Troitsk, Fryazino, Khimki, Khotkovo, Chernogolovka, Chekhov, Shatura, Shchelkovo, Shcherbinka, Elektrogorsk, Elektrostal, Elektrougli, Yubileiny, Yakhroma, Losino-Petrovsky, full list cities.

Foundations differ in the material of manufacture, in the degree of penetration into the ground, in the method of construction: driving piles, laying slabs, pouring concrete into the formwork. They are carried out either under the entire structure, or under its supporting elements (for example, under walls).

Monolithic foundations

Monolith is solid reinforced concrete structure, on which the supporting elements of the structure rest. Such foundations are strong, plastic, compensate for soil vibrations, do not transfer them to the walls of the structure, eliminate the risk of deformation and destruction. They can serve as the basis for any structures, from country country houses to high-rise multi-storey buildings. Suitable for soft soils, used in seismically active areas.

Disadvantages:high cost and energy intensity.

- A large amount of concrete and reinforcement is required.

- Use of heavy equipment is required.

- Formwork is required around the entire perimeter of the structure.

Price (material + installation) slabs 20 cm thick with a minimum distance of work - from 4 thousand rubles per square meter.

Construction time monolithic foundations, including floating and strip, for at least 28 days (due to the time required for concrete hardening).

A kind of monolithic for marshy soils, where seasonal fluctuations in water levels are inevitable. Feature: the design uses reinforcement that is not rigidly welded, the fixation points are tied with wire.

It is used in swampy areas and in areas with swelling soils. Almost the entire historical part of St. Petersburg is built on a floating foundation.

Tape filament

Truncated version of monolithic: reinforced concrete tape under load-bearing walls structures. It can be reinforced and reinforced-block (when the finished blocks are interconnected by cemented reinforcement).

Where is used

It is used as a support for stone, brick concrete walls, incl. on heterogeneous soils, where uneven settlement of the foundation is likely. Compensates for uneven settlement.

Suitable for the construction of structures with heavy walls and ceilings. Widespread for building fences and fences.

Popular in private buildings. Usually it is done buried (to the depth of soil freezing). For lighter buildings, shallow deepening is possible.

Advantages:

- versatile

- applicable in all regions

- withstands any climatic conditions and ground vibrations: thawing, subsidence, etc.

The cost - from 4500 per running meter.

Price table for strip foundation

| size, m | Recessed tape | |

| Width \u003d 300mm Height \u003d 1500mm | Width \u003d 400mm Height \u003d 1800mm | |

| 6x6 | 196.000 | 308.000 |

| 7x7 | 224.000 | 364.000 |

| 6x9 | 238.000 | 364.000 |

| 7x9 | 252.000 | 406.000 |

| 9x9 | 350.000 | 546.000 |

| 10x10 | 378.000 | 616.000 |

| 12x12 | 462.000 | 728.000 |

The finished slabs combined with each other serve as a support for the entire building. The foundation is universal, suitable for any soil. As a rule, it is not deepened.

Where is used

Suitable for the construction of multi-storey buildings. Ideal on soft soils with high groundwater levels. Often used in seismically active areas.

Price

The most expensive and energy-intensive type of foundation due to transportation and installation of slabs: from 5 thousand per square.

Approximate price table for slab foundation

| size, m | foundation thickness, mm. | ||||

| 250 | 300 | 350 | 400 | ||

| 6x6 | 126.000 | 154.000 | 182.000 | 210.000 | |

| 7x7 | 182.000 | 210.000 | 245.000 | 280.000 | |

| 6x9 | 196.000 | 231.000 | 266.000 | 308.000 | |

| 7x9 | 224.000 | 264.600 | 315.000 | 352.800 | |

| 9x9 | 294.000 | 350.000 | 406.000 | 462.000 | |

| 10x10 | 350.000 | 420.000 | 490.000 | 560.000 | |

| 12x12 | 504.000 | 616.000 | 714.000 | 812.000 |

Pile foundation (driven piles)

Foundation on screw piles

Metal piles, equipped at the end with blades, are screwed into the ground.

Advantages:

- Piles treated with anti-corrosion compounds are very durable.

- Reusable material: when dismantling the structure, the piles can be removed and used for another structure.

- High load-bearing capacity.

Screw foundations used in all regions of Russia and the world. Suitable for the construction of prefabricated (modular) structures.

Construction time - from 1 day.

Foundation prices:

With the minimum distance of work, the price for one 2-meter pile with material is 3000 rubles.

Screw pile foundation price table:

| Pile size | Cost per piece, rub | Head cost, rub | Cost of work, rub | total cost |

| diameter / length | ||||

| 57 / 2000 | 1050 | 250 | 1500 | 2800 RUB |

| 57 / 2500 | 1150 | 250 | 1500 | 2900 RUB |

| 89 / 1500 | 1500 | 300 | 1800 | 3600 RUB |

| 89 / 2000 | 1600 | 300 | 1800 | 3700 RUB |

| 89 / 2500 | 1750 | 300 | 1800 | 3850 RUB |

| 89 / 3000 | 1850 | 300 | 1800 | 3950 RUB |

| 108 / 1500 | 1650 | 300 | 1800 | RUB 3750 |

| 108 / 2000 | 1750 | 300 | 1800 | 3850 RUB |

| 108 / 2500 | 2000 | 300 | 1800 | 4100 RUB |

| 108 / 3000 | 2200 | 300 | 1800 | 4300 RUB |

| 108 / 3500 | 2450 | 300 | 1800 | RUB 4550 |

| 133 / 1500 | 2050 | 350 | 1800 | 4200 RUB |

| 133 / 2000 | 2200 | 350 | 1800 | 4350 RUB |

| 133 / 2500 | 2350 | 350 | 1800 | RUB 4500 |

| 133 / 3000 | 2550 | 350 | 1800 | RUB 4700 |

| 133 / 3500 | 2750 | 350 | 1800 | RUB 4900 |

The monolithic foundation of a house can be simple or reinforced, which in construction is called reinforced concrete. If, when pouring concrete, stones are added to it (their mass is 30-40%), such concrete is called rubble concrete. Its durability is no less than usual.

Reinforced concrete monolithic foundation is the most durable of all types, it can easily withstand various types of load.

When building with stone, it is possible to significantly reduce, which reduces costs.

Roofing material is used for waterproofing devices.

When pouring, a mistake is often made - allowing the soil, crumbling from the pit or the edge of the dug trench, to enter the concrete mixture. Soil trapped in the monolithic foundation significantly reduces the strength of the structure, leading to the formation of cracks.

Monolith care

An important stage of concreting is the care of the laid concrete. This is especially important in the first week after pouring. Concrete must be cured, adhering to the required temperature and humidity conditions. The recommended temperature is 18-25 degrees. Concrete must be protected from impacts, mechanical damage and other negative influences that contribute to the destruction of the concrete structure.

In hot weather, to avoid the formation of cracks in freshly laid concrete, it is necessary to periodically water the structure with water.

A freshly laid concrete foundation must be protected from wind, frost, direct sunlight. Under the influence of wind or sunlight, the monolithic foundation quickly loses moisture, which leads to cracks. In hot weather, the concrete is covered with a moisture-absorbing material (sawdust, dense fabric, burlap, etc.) and watered cold water... The formwork should also be moistened with water in hot weather. It is necessary to water so that the concrete surface is always wet. At negative temperatures, concrete must be insulated according to the principle of a thermos, for this they construct an insulated formwork, open surfaces are covered with special "warm" materials (sawdust, mats).

When building a house with a monolithic foundation at low temperatures, it is necessary to heat the concrete by blowing it with warm steam or air. Cements with a high heat release and fast-setting cements can be added to concrete that is laid at sub-zero temperatures. The most popular method is electric heating of fresh concrete.

Removing the formwork

Dismantling of the formwork must be started no earlier than 10 days after concreting. It is possible to load foundations with brickwork or ceilings after the concrete has completely set. If the monolithic foundation is made according to the technology, then during the operation the house will shrink evenly, without cracks and distortions. The longer you leave the formwork around the poured concrete, the better the adhesion of the formwork walls to the concrete will be, and it will be problematic to remove the formwork without damaging the top layer of the foundation.

The structure of the formwork must be disassembled very carefully, to prevent the corners of the foundation from crumbling, which may not yet gain the necessary strength. Defects found on concrete surface after removing the formwork (chips), it is necessary to clean it with a metal brush, rinse it with a strong pressure of water and wipe it with a cement solution (the ratio of cement and sand for such a solution is 1: 2). Large caverns and sinks must be cleared to the full depth until the "weak" concrete layer and protruding aggregate pieces are removed. Then the surface is again treated with a metal brush and rinsed with water under pressure. It is advisable to process large sinks with a hard concrete mixture.

Before the start of concreting, it is necessary to provide technological cavities for underground communications (sewerage, electrical cables, water supply). To do this, in certain places of the formwork, you need to insert and fix plastic or metal pipes with the corresponding cross-section of the diameter. During the construction of the foundation, they are covered with rags, tarred tow or other material with similar properties. After broaching the entire communication, the holes and gaps should be filled with a silicone compound or stamped with tarred rope. This is necessary so that the communication system is sealed and moisture does not get into it.

Didn't find the answer in the article? More information

- Monolithic reinforced concrete foundation

- What are formwork panels?

- Why is foundation reinforcement necessary?

- How to concrete a monolithic foundation?

- Signs of compaction of the mixture

- How to "take care" of the laid foundation

If you are going to build a house, then first of all you should worry about the question of the foundation. There are several options, one of them is a monolithic foundation. It can be simple and reinforced. The latter is often called reinforced concrete.

There is also rubble concrete - this is concrete, into which stones were added during laying at the rate of up to 30-40%. In terms of its qualities, in particular strength, rubble concrete is not inferior to concrete, but its use will greatly reduce the consumption of cement for a monolith foundation, and therefore will reduce the total cost of construction. Simple monolithic foundations are made of concrete grade 50 or more.

If you are building a monolithic concrete foundation with your own hands, then you will need to build a formwork from wooden boards or shields.

The walls of the pit can be used as formwork only if preliminary insulation is made with roofing material or a special film, otherwise the soil will begin to absorb cement milk, due to which the monolithic foundation will significantly lose its strength. Therefore, do not exclude the possibility that at some stage you will still have to seek the help of specialists.

Monolithic reinforced concrete foundation

Such a monolith foundation is rightfully recognized as the most durable and reliable. It does not sag under vertical and lateral loads, withstands the effects of moisture, it is possible to erect buildings of 2-3 floors on it, while there is no risk of cracks in the enclosing structure.

- The first stage is earthworks. They must be carried out immediately before the monolith foundation is being erected. The pit and trench should not be left open, as moisture will get into them. If water gets into the ground, the ground swells, due to which the monolith-foundation is lost. If water gets into the trenches, it is necessary to drain the pit, scoop out the water, remove the soaked soil, and after all this, strengthen the bottom of the pit, filling it with rubble, and tamp it thoroughly. Then pour the crushed stone with a cement solution so that the cement laitance does not flow out of the formwork.

- ? Formwork is a special structure that is installed around the entire perimeter, and is designed to give the necessary shape to the foundation while the concrete is setting. Under the monolith-foundation, the formwork is made of edged boards in such a way that there are no gaps between them. It is best to use inventory panels for formwork, as this will reduce the time spent setting the formwork and reduce the amount of work.

- What is inventory formwork? Inventory formwork is a reusable structure, and its main advantage is that there are many options for laying. This is especially important if a monolithic foundation is being constructed with a large number of corners. In addition, it improves the quality of the work performed and reduces the risk of the shields bursting due to the weight of the concrete. To fasten the formwork in its frame, holes for struts, tension hooks, bolts used to connect the panels can be provided different sizes, which ensures the accuracy of the installation.

- The pitch between these holes should be no more than 100 mm. For the manufacture of inventory formwork, it is better to use conifers, but hardwood, such as aspen, is also allowed. The width of the boards is recommended no more than 150 mm, and all boards must be of the same thickness. It is necessary to use raw boards, since dry boards will absorb moisture from the concrete, thereby reducing its strength. If necessary, the front side of the formwork is covered with plywood or metal sheets. Before this, it is better to coat the front side with grease to reduce the adhesion of the formwork to the concrete.

- As a lubricant, you can use milk of lime, mineral oils, an aqueous solution of liquid clay, and much more. If you make an internal lining, then this will allow with a very clean surface on the front side.

Back to the table of contents

What are formwork panels?

Whatever your foundation, the shields are installed at its full height. To fix the shields, you need to install and drive in stakes from their outer side (attach with nails). And it is necessary to unfasten the boards with wooden planks in order to avoid the divergence of the boards during the laying of concrete. In this case, all stakes, strips and other fasteners should be not in the space where you are going to lay the concrete. Otherwise, you cannot remove the fasteners.

How accurate and even your foundation will be, directly depends on how smoothly you set the formwork. This is of particular importance for the basement (ground part of the foundation).

After the stripping has been carried out, the foundation must be wiped with a thin layer of cement mortar, after which you do not need a special external finish.

Back to the table of contents

Why is foundation reinforcement necessary?

Unreinforced concrete copes very well with compressive loads, but poorly - in tension and bending, so reinforcement is done in order to make the concrete even more durable, and thus it turns into reinforced concrete. For reinforcement, steel metal rods or welded frames are used. Thus, monolithic foundations become much stronger.

If you choose the right fittings, aggregates and binder, you will get a powerful structure that can withstand enormous loads. It is important to use the reinforcement without contamination, rust and grease, as this will reduce the ability of the reinforcement to adhere to the concrete and, accordingly, reduce the overall strength of the structure. Which diameter, profile and size of reinforcement is best used depends on the construction project.

If you are going to use a reinforcing cage, then for welding it right on the construction site it is better to attract specialists who have permission to do this kind of work and experience.

When reinforcing bars are installed in the formwork, their displacement is allowed no more than 1/5 of the largest diameter of the bar, and the deviation is no more than 3 mm (if the concrete cover is up to 15 mm) and no more than 5 mm (if the concrete cover is more than 15 mm) ... After installing the reinforcement, it is imperative to check the formwork, and if you find any defects, then eliminate them.

Back to the table of contents

How to concrete a monolithic foundation?

Concreting should not be performed if the outside temperature is below zero. If, nevertheless, concreting is carried out in the cold season, then you need to think in advance about measures for warming the mixture after laying. This is due to the fact that frozen concrete significantly loses its strength and begins to crumble. If, on the contrary, concreting is carried out in very dry weather, then the formwork is moistened before this. This is done so that moisture from the concrete does not go into the wooden formwork. All these measures are mandatory, since if they are not observed, the monolithic foundation will not be so strong and durable.

Concrete is delivered to the construction site by transport or prepared directly on site using special concrete mixers. It is undesirable to transport concrete on dump trucks, as during transportation the concrete is stratified. Therefore, it is better to transport concrete on concrete mixer trucks, and during delivery the concrete is mixed in them and does not lose its quality.

Concreting is carried out in several layers, with each layer being compacted. The concrete is delivered to the place of laying in a special bucket or through a concrete paver.

Concrete supply rules:

- with free dumping of the mixture, the height should be no more than 2 m;

- if the descent is carried out from a height of more than 2 m, then it is carried out along vibrating channels, which ensures a slow descent of the mixture without stratification of the composition.

What is the most reliable way to compact concrete?

Vibration is considered the most reliable. For this purpose, several types of vibrators are used: internal (deep), surface (area) and external vibrators. The choice of a vibrator depends on what type of foundation monolith construction is used.

It is necessary to vibrate the monolith foundation so that the adhesion force between the grains of the mixture decreases, due to which the mixture is better compacted. But excessive vibration should not be allowed, as this can cause the mixture to stratify.