The strength of aerated concrete blocks for bearing walls. Bearing walls from aerated concrete - selection of blocks and proper construction

The modern building market presents a wide range of materials for capital construction. This article will consider the bearing walls from aerated concrete - characteristics, influence on a person and the method of building houses with their application.

There are different manufacturers, brands and geometric forms of such products. For this reason, the appearance of a fuel-concrete blocks in the photo may differ from real proposals. General principles Manufacturing and use are valid for all species of this material.

Mesh concrete is divided into three main types and density brands.

The digital parameter indicates a mass kg / 1m 3 substances:

- Construction - D1000-D

- Construction and heat insulating - D500-D

- Heat insulation - D300-D

Already the names show that the brand of aerated concrete for the bearing walls D500 - D1200. For comparison, the main characteristics of cellular concrete and brick are presented.

| Panstone for bearing walls | Brick | |

| Weight 1m 2 carrier wall, kg | 150-200 | About 1000. |

| The environmental coefficient (the smaller the better) | 2 | 10 |

| Density, kg / m 3 | 500-1200 | 1500-1900 |

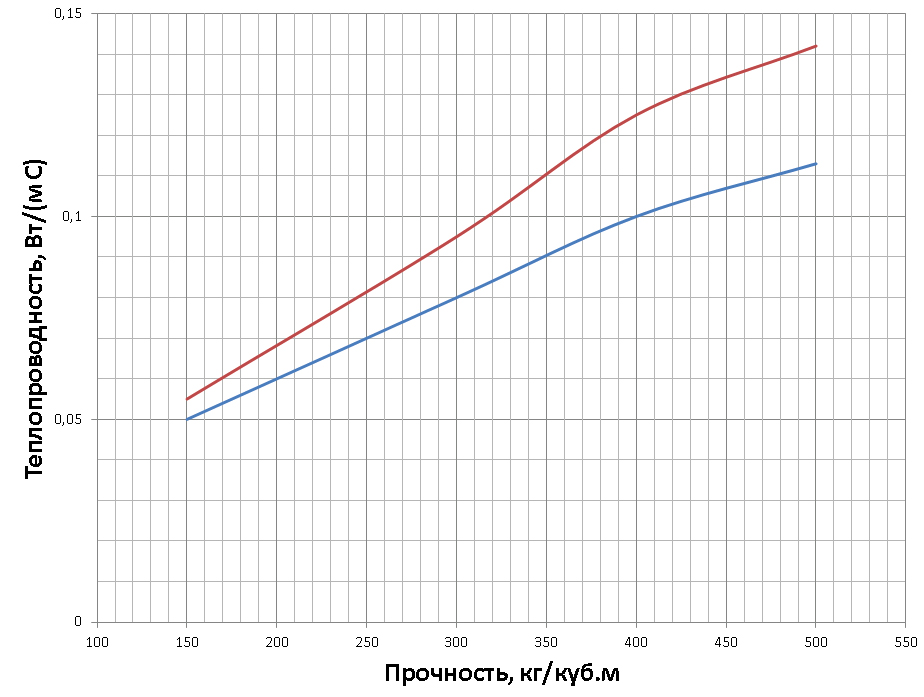

| Thermal conductivity, W / m * to (less is better) |

0,2-0,38 | 0,6-1,15 |

| Frost resistance, cycle (the more, the better. MIN 15) | 35 | 80 |

| Water absorption,% relative to the mass (the less, the better) | 20 | 10/12/17 |

| Compression strength, kg / cm 2 (the more, the better. Min for single-storey buildings 10) | Up to 50 | 110-120 |

Under normal conditions, the density of aerated concrete for bearing walls is calculated on the table:

| 1st floor | 2nd floor | 3rd floor | |

| One floor | D500-D600. | H. | H. |

| Two floors | D700-D900. | D500-D600. | H. |

| Three floors | D1000-D1200. | D700-D900. | D500-D600. |

The minimum thickness of the bearing walls from aerated concrete should be 250 mm. Depending on the special conditions of the terrain, the floors and complexity of the architecture, an individual calculation is made.

Ecology

Among people unfamiliar with the production technology of Gasubeton (the second name is cellular concrete), there is an opinion that such material is harmful to human health. To understand this issue, you should explore the components and method of manufacturing these blocks.

Components:

- quartz sand, it is used to give strength, absolutely harmless - 60%;

- cement, in the composition of the block is in the associated form - 20%;

- limebaked at high temperature - 20%;

- aluminum dust - About 1%.

By its structure, the blocks of aerated concrete for carrier walls are 50% consisting of air bubbles, which means the substances content indicators should be divided by half. We get: cement - 10%, lime 10%.

In a conventional wall, where every brick is covered with a solution from all sides of cement at no less, but no one is afraid of it.

But that's not all:

- During the technological process, all components are mixed between themselves in wet.

- Aluminum reacts with lime, hydrogen is distinguished, which creates impacts from the mixture. These voids are filled with ordinary air, after which the composition is placed in an autoclave.

- Further treatment passes at a temperature of 190 o C and pressure 14 atmospheres.

- Quartz sand in such conditions enters the reaction with foamed cement and lime forming a homogeneous mass.

- After cooling, we get an artificial substance from which the cement is removed and the lime can only be placed in the case if it is placed back to the same conditions.

Thus, the usual cement-sand mixture, from which dust with dust conditions, is much more harmful. Aerated concrete for bearing walls, if they do not eat, is absolutely safe.

Advantages and disadvantages of cellular concrete

Features chemical composition, production technology and physical properties They give a cellular concrete a number of advantages over other materials.

- High accuracy of geometry makes it easy to observe the desired size and rigidity of the masonry.

- Large, compared to the brick, the size of the blocks significantly reduce the construction time.

- The ability to retain heat allows to reduce the thickness of the walls.

- Mesh concrete easily cuts and processed by a hand tool.

- The small weight of the material reduces the load on the foundation, which allows you to significantly save the budget.

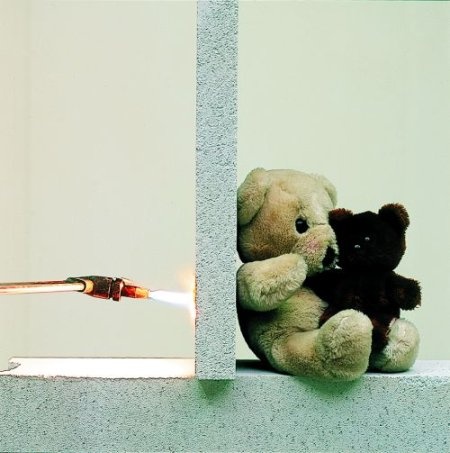

- Gas blocks - fireproof material.

By choosing a bundle for bearing walls, it is necessary to take into account not only its advantages, but also disadvantages.

- Cellic blocks have a porous structure, so water is easily absorbed. It is necessary to ensure good protection against moisture.

- The stuff of blocks is in the baked condition, prone to cracking in places of elevated loads. For this reason, the minimum thickness of the bearing walls from aerated concrete must be correctly calculated. AT dangerous places Requires masonry.

One of the important is the fact that even when providing qualitative measures for strengthening and waterproofing, the price of 1M 2 carrier walls from aerated concrete remains the most attractive among competitors.

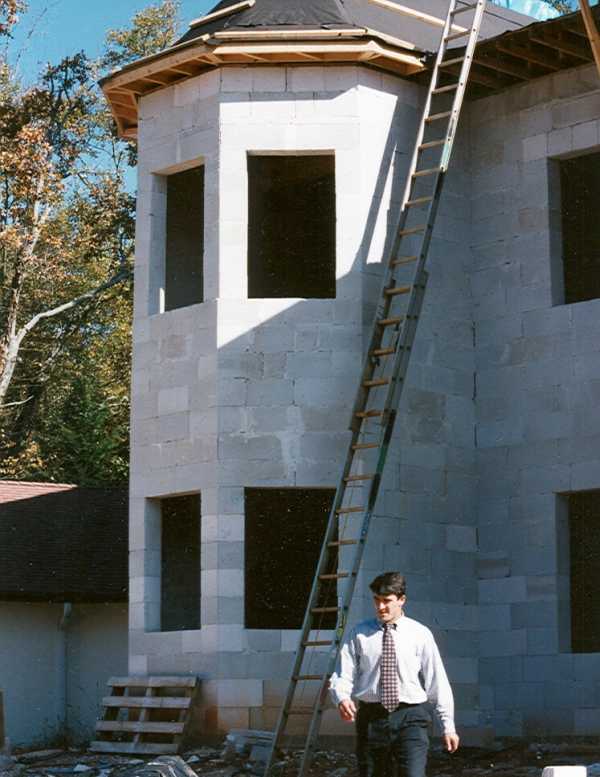

Construction of aerated concrete bearing walls

Like any other material, aerated concrete blocks for bearing walls require compliance with certain technologies. This section provides detailed instructions On the device of bearing walls from cellular concrete with their own hands.

Attention! Without having experience in construction to determine which one should be the minimum thickness of the carrier wall from aerated concrete in a particular case, be sure to contact the specialists.

Unloading and warehousing

Manufacturers release their products on pallets, while the upper part or the entire stack is coated with a polyethylene film. In addition, the packaging can be tangled.

- It is best to use a loader to use the material.

- Stacks can be stored in two tiers.

- When manually unloading, use the existing pallets as a stand for lower row and gaskets between tiers.

- The top row should be covered with film or infirred materials.

Thus, the integrity of the blocks and protection against precipitation and flooding is observed.

Properly laid out the bottom line will provide smooth rows of further masonry, the strength of the wall and the convenience of work. Most often, the foundation or base does not have a smooth upper plane.

In addition, the waterproofing between the wall and the base of the house is obligatory. If you do not provide reliable protection against water, the whole wall will absorb moisture, which will freeze in the ice in winter and will destroy the building.

- With the foundation, all foreign elements are removed and dust sweeps.

- The rolled waterproofing material is stacked. Its width should be greater than the minimum thickness of the carrier wall of aerated concrete.

- Along the extreme lines of the external and inner sides of the future wall, thick, wide strips of the leveling solution are applied. You can apply a conventional mixture of cement and sand. With the calculated load up to 70% permissible, the average is better to leave free from the mixture. This method will provide the opportunity to easily set the blocks to the right position, will protect against dampness and will prevent the heat leakage from the room.

- Along outside The foundation for the entire length of the wall clearly horizontally stretches the estimated cord, the construction name "pier". The height of the placement berths counts from the top level of the cement solution to the height of the minus 5-10 mm block, depending on the degree of irregularity of the foundation.

- By installing the first row, the top outer line of the blocks orient on the cord. At the same time, it is left to the berth about 1 mm. It is impossible to contact aerated concrete and cord, as it can break the wall line. The top plane of the blocks orient horizontally using a level.

![]()

- The position of each individual block is exhibited by a rubber hammer.

- Before applying the glue layer, it is imperative to carefully remove dust. Small dry particles prevent the adhesion process of glue and aerated concrete.

Need to know! By mounting a row, you need to lift the places of the joints before the formation of one plane without the "step". The presence of a protruding face may result in a fracture of the elements of the next row.

Properly arranged the foundation of the house, you can move to the construction of walls.

Construction of the main wall

It is greatly facilitated by the workflow of simple devices that help to make the wall smooth and observe the vertical. Called such assistants - order. For its manufacture, a material that has one straight side is suitable.

It can be a wooden rail, any strip or fragment sheet material With the factory edge. You can store aerated concrete blocks for bearing walls at the corners of the future building. Stacks will be landmarks that do not need to be placed in height.

- Spitches are installed so that their smooth sides rise vertically from the opposite external angles of one wall of the first row. Fixed into the lower blocks or infirred means.

- At the distance from the upper plane of the previous row equal to the height of the block is set by the pier.

- In the future, having a lower plane and the restrictive cord along the upper face easily and quickly sets the next row.

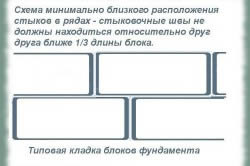

- The joints of the neighboring rows should not be one line. There is no less than 10 cm between the seams. To ensure this condition, a fairly angular unit should be put so that it covers the joint between the bottom elements of the wall.

- The length of the wall glue is applied with lines that do not come into contact with each other. For this purpose, the usual toothed spatula is most often used. If the volume of construction big makes sense to acquire a special carriage.

- On the ends of the blocks only the outer and inner sides are punctured. The middle part is not filled.

- In each row, it is almost always necessary to install a part of the block. Given the low density of aerated concrete for bearing walls, cut the desired fragment will not be difficult. If the wall has a door or window opening, the cutting side orient to the impact. In cases where this is not possible, the non-standard end is covered with glue as well as a layer between the series.

- It is allowed to smoke ends only on the side that will not be plastered. This method speeds up the construction process, but in the event of a breakdown layer, there is free access of moisture and cold inside the wall.

- In cases where the part of the wall is mounted, which is in the ground, or it is necessary to increase the rigidity of the overall design, the end joint is completely filled with glue.

Important! In some places of masonry or, if necessary, reinforcement due to specific conditions, reinforcement of the carrier wall. As an amplifier, an armature with a diameter of 8 mm or special reinforcing frames is used.

The reinforcement is placed in the shoes, and the frame is packed in the glue layer.

![]()

After reading the technology, and correctly using aerated concrete blocks for bearing walls, even not having special skills a person can independently be accepted for the construction of a house according to the calculated project.

- Aerated concrete - modern building material

- Technology made of aerated concrete

- The main quality of aerated concrete

- Strength of aerated concrete

- The problem of using aerated concrete

- Choosing a foundation of a house of aerated concrete blocks

- Problems of growth of the cost of a house of aerated concrete blocks

Aerated concrete - modern building material

Many newly newly believes that the most best Material For a new house - a tree. Of course, the living spirit and smell of wood gives special comfort to such a house. But its construction is not for everyone to pocket. Is it possible to find a budget version of housing? Of course. This material is aerated concrete and aerated concrete blocks. Residential houses from aerated concrete blocks have become popular today. They are inexpensive, environmentally friendly, cozy, possess the ability to maintain heat in the house for a long time.

Until the end of the 20th century, brick and concrete slabs were mainly used in construction. In modern conditions, high demands on building materials are imposed. They must be environmentally friendly, efficient, durable and durable. This is necessary to comply with the conditions for comfortable residence of people and compliance with a healthy lifestyle. This requirements fully respond to aerated concrete blocks.

Today, aerated concrete is an effective, widespread building material with unique properties. The technology of manufacturing aerated concrete blocks is complex, as labor-intensive production operations are performed. For the production of aerated concrete blocks, large capacity is required, modern production lines and skilled labor. Aerated concrete blocks are needed in the field of construction, during repair and restoration work. Its production in the 60s of the 20th century was cost-effective, well-proven himself. Many buildings previously erected from this building material are successfully operating today.

Now, in the 21st century, the serial industrial production of aerated concrete is reborn. Production volume is growing, the sale of this building material is expanding. Advertising campaigns contributed to an increase in demand for cellular aerated concrete. This is due to its attractive qualities.

Back to the category

Technology made of aerated concrete

Aerated concrete refers to cellular concrete. It has no concrete filler, but there are end-to-end, artificially created pores created using cement, sand, and other components.

This raw material is enough on our planet. It can be easily mined without causing significant harm environment. The processing of these components in a mixed form is performed in the autoclave. Here, in the specified conditions, foaming of the source material is made. At the same time, the reaction of corrosion of aluminum powder and the release of hydrogen, forming through pores. Next is the process of hardening the composition. Depending on the method of formation of pores, there are 3 types of cellular concrete. Among them are aerated concrete, aerated concrete blocks. The main components in aerated concrete blocks are actually homogeneous. Only the foaming and the hardening methods that are used in the process of producing aerated concrete blocks are distinguished.

In autoclave, manufacturers receive aerated concrete and aerated concrete blocks that have the characteristics necessary for building materials. In 2011-2012 Examination was carried out by technical experts in Russia building materials in cottage settlements. According to their results, the aerated concrete received a high assessment of specialists.

Back to the category

The main quality of aerated concrete

First of all, it is distinguished by excellent bearing capacity, strength. Under the strength is understood as the fortress of the block when checking for compression, that is, its carrying capacity. This is the most main characteristicwhich has aerated concrete. Studies of technical specialists have shown: high-quality aerated concrete has a compression strength of about 35 kgf / sq. CM.

The strength of the aerated concrete is directly dependent:

- From the quality of raw materials purchased by a manufacturer of aerated concrete for its production.

- From compliance with production technology.

Back to the category

Strength of aerated concrete

The level of strength of the material of the walls of the aerated concrete blocks depends on the amount of water in the cement solution. The strength of the aerated concrete is reduced as the relative amount of water increases in it. Excessive water spreads small parts of cement. As a result, emptiness and pores are formed. The increase in the strength of the materials contributes to the decrease in the ratio of water and solid components of the cement mortar, as well as the use of vibration and reinforcement solutions in the preparation of solutions.

For example, when the rate of the strength of the feline-concrete block of class 1.5 is D500, it is forbidden to build the carrier walls of a 2-storey building from it. Using one of the most popular brands of the D500 of the D500, the range is higher than in 1.5, it is possible to build buildings whose height is not more than 3 floors, since the density is high enough and is 500 kg / kV. Under these conditions, aerated concrete blocks will be able to fully withstand the load from the design of the house and the slabs of the overlap.

Back to the category

The problem of using aerated concrete

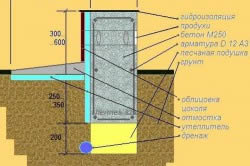

However, there are both positive and negative moments when working with aerated concrete blocks. The view is that since the aerated concrete attributed to lightweight materials, it is possible to save on the construction of the foundation, is erroneous. Do it irrational. After all, the purpose of a good foundation is to provide a constant form of structure. Attempts to save on the construction of the foundation increases the likelihood of cracks in the walls during the shrinkage of the building. It is better to use various types of tape monolithic foundations. The disadvantage of aerated concrete is that it largely depends on any shifts during the shrinkage of the house and from various kinds of deformation, since it is a fragile material because of its fragility. First of all, it is important to choose the right foundation.

Back to the category

Choosing a foundation of a house of aerated concrete blocks

But choosing the right foundation for the house of aerated concrete blocks is difficult. An excellent option will be the choice of slab foundation. This foundation is capable of climbing and descending into periods of seasonal hesitation of the soil. An excellent option that minimizes shrinkage deformation, reinforced concrete plates. Before you start the bookmark of the foundation, according to the building project, you need to dull trenches. The trenches of this foundation must be protected so that water does not get there. For this, adjacent sites must be equipped and a water was created. Trenches, where the foundation is arranged, must be necessarily fixed.

It is also possible to build a pile foundation under a gas-concrete building. However, you need to consider that pile Fundam For the structure of aerated concrete, it is not necessary to create on a movable soil, as it is not sufficiently stable. The advantage of such a foundation is that it is possible to drill them using the usual manual construction boring.

The monolithic ribbon foundation is needed that the deformation is minimized during shrinkage, the risks of significant cracks in the masonry. Optimum option - reinforced concrete plate. It can provide uniformity and minimum parameters of shrinking deformations. Creating a slab foundation is quite expensive. However, these costs justify themselves.

You need to take the right decision, what a foundation for the structure of aerated concrete blocks you will create. Your choice will depend on the characteristics of the soil, the parameters of the built building. It will help to protect the house from significant deformations.

To prevent cutting plates overlapping of aerated concrete blocks, you need to use a special reinforcing belt for the foundation. If there is no such possibility, the use of reinforced concrete pillows for support is allowed. You can use bricks that need to be laid according to special technology. But these additional components of the structure reduce the properties of thermal insulation.

Back to the category

Problems of growth of the cost of a house of aerated concrete blocks

Since for building buildings above the third floor, a high density aerated concrete is required, such buildings are usually not erected, since the thermal insulation properties of the house are significantly reduced, and its cost increases. This leads to a significant increase in the cost of building the construction.

Construction of a strong can do in a very large amount. Therefore, in this case, the aerated concrete is inappropriate.

It is allowed to use aerated concrete and more high buildings. But in practice, construction firms implement it infrequently. This is explained by the fact that in these cases it requires the use of more dense aerated concrete blocks. But, firstly, their cost is several times more expensive. Secondly, this type of aerated concrete blocks do not provide sufficient thermal insulation. In addition, on the material from these aerated concrete blocks, it is often necessary to fix any massive design. But it is difficult. In addition, it uses much more expensive, special fastener technology. In general, if the average cost of the facade of an economical cottage is approximately 500 square meters. meters, it will be more expensive for 125 thousand rubles. This amounts to almost half the price of aerated concrete blocks for this cottage.

Thus, we see that the use of aerated concrete, which initially has low cost, in some cases requires additional costs. Moreover, aerated concrete is a rather fragile material. For example, he is so inelastic that it has the ability to easily break when flexing. This property of aerated concrete can not be taken into account in the construction process. With the slightest deformations of the foundation, massive cracks of the entire design may appear. Low elasticity of aerated concack can be compensated by stone hardness. Most often for this use autoclave aerated concrete. It is made on the technology of exposure to a saturated ferry. At the same time, pressure indicators should be much higher atmospheric.