Fire resistance of metal structures without fire protection. Fire retardant paints for metal structures and air ducts

Strong and durable metal structures are widely used in the construction of residential, industrial and public buildings. They are especially relevant for the construction of warehouses, airports and stadiums. However, in the event of a fire, metal elements quickly heat up and lose their strength. For example, metal beams, heating up to 500 ° C, collapse in 10 minutes. To protect an object from the negative effects of fire, you need to take care of its protection, which increases the fire resistance up to 150 minutes.

The AVS Stroy Zashchita company offers high-quality and reliable paints for reliable protection of metal structures. They are of impeccable quality and durability, and also meet all fire safety requirements and GOST.

The advantages of fire retardant materials offered by our company include high quality products, regardless of their type and cost, environmental safety and no additional load on the structural members. One of these formulations is Teksotherm.

"Fire retardant paint" - reliable protection for your object

The coating is an organic-based, fire retardant polyacrylic enamel that is produced in strict accordance with technical specifications. The dry residue in Teksotherm is 70% or more. This intumescent coating provides passive protection for metal structures against performance and strength degradation. In case of exposure to open fire on structural elements and temperature rise above 200 ° C, Texotherm swells, forming carbon foam, which protects the object from heat and fire, and also increases the fire resistance coefficient from 45 to 120 minutes.

The advantages of fire retardant paint include:

- short drying period;

- little time to prepare for additional coating with all kinds of paints and varnishes;

- the ability to apply a large amount of material in one pass.

In addition, the enamel has high adhesion to the substrate, resistance to mechanical stress and abrasion. The coating is plastic when the temperature rises to 40 ° C or when the temperature is abruptly heated by more than 25 ° C. However, a slight increase in thermoplasticity does not affect the working qualities of metal structures.

The ABC Stroy Zashchita company offers to buy fire retardant materials at competitive prices. All the products we offer are of impeccable quality, meet all the declared characteristics and have the appropriate certificates. We offer materials in the amount you need. Mutually beneficial cooperation allows you to reduce the cost of metal fire protection and be confident in their quality.

You can find out the cost and other nuances of cooperation by calling our company representatives or by visiting our office.

Although metal is a highly durable refractory material, exposure to high temperatures is detrimental to it. It rapidly loses its strength, which is extremely dangerous for load-bearing structures and elements under constant load. Therefore, they need special protection to reduce or completely prevent the effects of high temperatures on the metal for a certain period. For this, fire retardant paint is used for metal structures.

Types of fire retardant coatings and their basis

Fire retardant paint varies in degree of protection, properties and application characteristics. Two types of such coatings are noted: intumescent and non-intumescent. The second option is expensive and not very popular among consumers. Therefore, the most common type of such coating is intumescent paint.

Intumescent paints are also called intumescent. This name appeared due to three groups of reagents, which provide good protective properties of the material. Three types of such substances are noted:

- Nitrogen-containing reagents.

- Phospho-containing acids and their derivatives.

- Polyhydric alcohols.

Each fire retardant paint of this type consists of 40-60% of these materials. The listed components perform well the functions of a paint and varnish coating, and when the temperature rises, they perform gas generation and, on the basis of their composition, create a coke layer that reduces the effect of high temperatures on the metal.

Each of the components is responsible for its task both in the passive period (in the form of paint) and in protection from fire. Although the principle of operation of the paints is the same, the composition can be slightly different. Among the nitrogen-containing substances, melamine, urea or dicyandiamide can be used. These components reduce paint wear, as well as contribute to the formation of a protective layer and ensure its heat resistance.

Among the polyhydric alcohols, the following substances are used:

- pentaerythritol

- dipentaetrine

- starch

- dextrin

These polyols act as a coke catalyst to aid in the protective layer process. They also provide protection against burnout and improve adhesion of the substance.

The last type is phosphate-containing acids. They improve adhesion, ensure the durability of the coating and its resistance. But in the event of a fire, these substances significantly increase the speed and degree of swelling, preventing smoke formation, smoldering and combustion. Among them are melamine phosphate, ammonium polyphosphate, ethers and salts.

Interesting ! In the process of foaming, the paint does not emit toxic substances, so its use is safe for people around.

All of these substances are the basis of fire retardant paint. They contribute to the formation of a protective foam layer and prevent the heating of metal structures. High-quality flame retardants will keep bearing structures buildings during especially strong fires, protecting it from destruction. Therefore, they are used everywhere.

Work of coatings at high temperatures

Under normal conditions, fire retardant paint is practically indistinguishable from ordinary paint. Although it has great strength and durability, external differences are minimal. But its features begin to appear when high temperatures occur.

Heating the paint is a catalyst for the process, starting the synthesis of porous oligomers, their formation and curing. The speed of these processes and other characteristics of the coating depend on its composition, conditions of use and temperature.

The process of developing a fire retardant coating consists of several stages:

- Isolation of gaseous products. The protective layer in the form of a gas promotes subsequent reactions and prevents the unformed paint layer from being exposed to high temperatures.

- Release of phosphoric acid. This triggers the synthesis of a base for fire retardant coke foam.

- Foaming agent destruction. The rise in temperature destroys the bonding element, which creates a gas cushion in the foam that isolates the metal from temperatures.

- Decomposition of phosphate-containing substances. This is the peak of the foaming reaction at 360 ° C.

- Pyrolysis of network structures. It occurs at a temperature of 340-450 ° C. It is accompanied by violent foaming of the protective layer.

As a result, an insulating coke bed with gas-filled voids is created, which reliably protects the metal from heating.

The onset of the reaction occurs at 250 ° C. This figure was selected on purpose, because it is at this stage that a rapid decrease in the properties of the metal and its strength is noted. In the period from 250 ° С to 400 ° С, it gradually loses its qualities, after which it gives in to minimal loads.

Interesting ! Among modern fire retardant paints, there are compositions capable of working at 1200 ° C. The standard is 800 ° C.

The duration of paint protection depends on its composition and group. Now there are 7 groups that prevent the effects of fire on metal in the period from 15 (7th group) to 150 minutes.

Popular brands of fire retardant paint

Since the composition and quality of such paints and varnishes are extremely important, there are favorites on the market whose products can be trusted to protect the supporting structure. There are several popular options, including:

However, there are other popular options available in the market. They differ in the substances used and their ratio, which significantly affects specifications cover.

Important ! Various compounds are often mistaken for fire retardant paint. They do not belong to paint and varnish coatings, but are more effective in protecting metal structures.

Application of fire retardant paint

The quality of application of fire retardants directly affects the degree of their effectiveness. Therefore, it is important to properly prepare the surface and create a reliable layer that will not collapse over time. To do this, follow these steps:

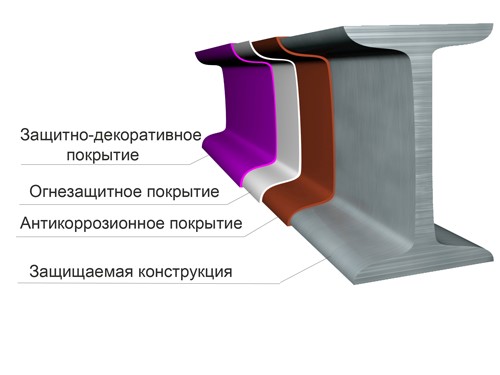

- Surface preparation. The metal surface is thoroughly cleaned from various contaminants, corrosion, mineral and oil substances. Cleaning is carried out mechanically or abrasively. Remove any dust and degrease the metal prior to application.

- Primer. The fire retardant paint should always be applied to the primer. For this, the GF-021 soil is recommended, but other options are also possible. The primer must dry before applying paint.

- Preparation of paint. The composition must be thoroughly mixed with an electric low-speed tool (mixer). Then wait about 20 minutes to eliminate air.

- Application. It is recommended to apply the coating by airless spray. For small areas, you can use a brush. It is not recommended to use a roller, it can reduce the uniformity of the coating.

Important ! Consumption per layer depends on the specific composition. It is worth focusing on 1.5-2.5 kg per meter, but this figure varies from layer thickness, application method and paint density.

The coating is applied in several layers to increase the degree of protection. One layer will simply not be enough to resist high temperatures. It is recommended to apply 2-5 coats for maximum fire protection.

A protective and decorative coating can be applied on top if the structure is often in sight.

Fire retardant paint is an effective protection to keep your building safe in case of fire. It will protect metal structural elements from fire, creating a foamy layer around them. There are many brands and formulations, but the action is similar for all. Therefore, it is worth choosing based on your own preferences and requirements.

And for a better understanding of the action of such coatings, it is recommended to watch a video where the paint is affected with a gas burner:

Fire retardant metal treatment in the structures of buildings and structures - this is a mandatory procedure that protects against fire. Special treatment significantly reduces the risk of flame spreading inside the building. However, this is not the only reason why a flame retardant metal treatment is required.

Five reasons to protect metal from fire

- First of all, the means for protecting metal from fire help to save human lives. First, the likelihood of flame spread is reduced.

- Secondly, flame retardant for metal reduces, and in some cases even prevents the likelihood of intoxication poisoning.

- Thirdly, metal processing with fire retardants can reduce material losses. Since the fire has no way to spread, valuable property located in other areas of the building will remain intact. It is worth noting here that various equipment and machinery will also remain intact. However, not only things and objects will be safe, but also the supporting structures, and this turns out to be more important, since the probability of the structure collapsing will be minimal.

- Fourth, timely fire-retardant treatment of metal leads to a reduction in the time it will take to extinguish a fire in the future. Since the fire will be limited in area, it will be much easier for firefighters to extinguish the flame and carry out all the necessary work.

- Fifth, the increase in the time during which the building structure will be able to resist the effects of fire should be noted. This means that people in a burning building will have more opportunity to leave it unharmed.