Parameters and types of metal profiles. What types of work is the metal profile used for?

It is very easy to mount light and flexible structures like drywall, even for a beginner. The main thing in this matter is to correctly install the metal frame under the base of the finishing building material, the rest will already go like clockwork. A modern profile is usually made from very thin but durable plates, which are mounted to the surface using self-tapping screws using screwdrivers or drills with special nozzles.

Types of metal profiles

Profile pipes differ from any other types of pipes in that they have a cross-section that is always different from round. The size of the pipes affects the scope of their application: the larger they are, the greater the load they can take on (the dimensions of the section itself can be very different: 20x20, 20x40, 40x40, 50x50, 60x60 mm and others).

According to GOST, pipes according to production technology are subdivided into the following types:

The profile pipe can be different sizes

The profile pipe can be different sizes hot-deformed;

- cold-deformed;

- electrowelded;

- cold-worked electrowelded.

The first and second types are seamless. Such pipes are widely used due to their good qualities:

Profile for installation of drywall

Rack

The rack-mount aluminum profile has the international marking "CW". Used for the installation of plasterboard partitions and walls, always inserted into the guide.

- 50x50 mm (it will not work to insert insulation into it, but using this size will significantly save space in small apartments);

- 75x50 mm (used relatively rarely - mainly when installing partitions and decorative panels);

- 100x50 mm (it is very easy to put almost any insulation in it).

In general, here it is necessary to select a standard size based on specific needs.

The most important parameters for the rack profile is the wall height

The most important parameters for the rack profile is the wall height Ceiling

It has the Western European marking "CD", usually T-shaped, fixed directly to the ceiling itself with the help of special suspensions. The frame of the ceiling is formed from it. To simplify installation, various additional elements are used, with which the profile can be given any shape:

The ceiling profile is the easiest to install from a technical point of view.

The ceiling profile is the easiest to install from a technical point of view. - straight suspension;

- suspension with anchor clamps;

- crab (used to connect parts at right angles);

- extension cords and connecting fittings.

Many builders do not recommend using a crab in their work, as it can deform the profile. Because of this, it is better to use it when installing a profile of large thickness and size - in this case, the crab is unlikely to contribute to deformation.

The device of the frame from the profile under the suspended ceiling

The device of the frame from the profile under the suspended ceiling Guide

PN has international markings "UW" and "UD" (for mounting the frame - one marking, for mounting on the ceiling - another). The thickness of such a profile is chosen based on the thickness of the wall itself, on which the frame must be pulled.  Example of a guide profile

Example of a guide profile

It is worth distinguishing between the guide profile for the ceiling and for the frame - they have different characteristics even in the composition of the metal from which they are installed.

For installation you need the following tools:

- scissors for metal (for cutting the necessary profile elements);

- divider (needed so that later it would be easy to connect the elements in the corners);

- a cutter (with its help, holes are created for attaching the profile).

Angular

As you might guess, it is used to strengthen and align the profiling nodes. The thickness of the "corner" usually varies from 4 to 9 mm and is selected based on the thickness of the main profile (if the thickness differs, it will be quite problematic to align the same corners). Such a profile is produced immediately with an angle of 85 °, which allows it to ensure its most dense and even contact with the drywall itself.

Bent (beacon)

It is usually used for leveling walls. In fact, it is a small rail on which the rule walks. Most often, a beacon profile is used, it is not difficult to guess during work on plastering walls.

The beacon profile always has many holes

The beacon profile always has many holes Today in the construction market you can find all types of profiles for drywall, there should definitely not be any problems with the purchase. You can give a little advice: do not save too much and buy the products of Chinese steelworkers.

It is better to overpay 20% -30% more, but buy a really high-quality metal profile of Western European or even domestic production. The length of the profile does not matter.

Roof profile

The iron profiled sheet is the most widespread roofing material on the planet, used everywhere. Except for the regions of the Far North and other regions with specific natural conditions. This suggests that it is possible to use a profiled sheet as a roofing material almost throughout the country, regardless of where the house is being built.

Profiled sheet - the cheapest roofing material at the moment

Profiled sheet - the cheapest roofing material at the moment It is also used as a material for gates, to fasten various structures, you can build a garage from it, make sheds, doors and mount a fence (a wicket is attached) - the scope of its use is not limited to one roof. The professional sheet has the following advantages:

Do not confuse corrugated board with metal tiles - they are still different things. Moreover, metal tiles are not even a relative of real tiles, but a completely different material. Before buying roofing material, all these nuances must be clarified in advance.

The square-section thermoprofile is an ordinary steel beam with perforation, its maximum thickness. It is used only in the construction of pre-fabricated buildings (this happens using a specially developed technology). When erecting a building according to the usual scheme (not prefabricated houses), the use of a thermal profile, in fact, is meaningless. This type of profile has the following positive characteristics:

Components that will be needed for mounting the profile

The list of components is not that long:

Instead of corner connectors, you can use single-level connectors - they will come out cheaper in cost. However, do not forget about the possibility of deformation of the frame when using the "crab".

The most common types of defects in components

Fittings and fasteners often have the following types of defects:

- the metal has a very small thickness (the screws will simply scroll - all the work will go down the drain);

- if there are traces of rust on the fasteners, the corrosion process will continue, it is absolutely impossible to buy and use such components;

- incorrect rolling (you can take an element and take a closer look at it - if it is completely "twisted", then you cannot buy it - then there will be many hours of torment trying to set profiles);

- inaccurate dimensions (coupled with a small metal thickness - the most "dangerous" type of marriage).

Video

You can watch a video about the types and sizes of metal profiles.

Easy to install and maintain, as well as externally attractive materialmade of corrugated metal is called a metal profile. It is used when arranging the roof, for the construction of fences and gates. Profiled sheeting has been used in the construction industry for a long time and successfully. Every year this material becomes more and more popular and in demand. Today manufacturers offer the attention of consumers different types metal profile, and each of them is intended for specific work.

The variety of the assortment is striking, despite the fact that the material outwardly seems simple (see photo). To make the final choice and determine which types of corrugated board correspond to the planned work, you need to know their parameters and characteristics.

Types of corrugated board

For different purposes, manufacturing companies make different types. Before buying, first of all, you need to pay attention to the first letter in the product labeling.

If this is H, then such a sheet belongs to the most durable profiled products. The letter means a supporting corrugated board, which has the greatest thickness and height of the corrugation, and additional grooves give it increased rigidity. Due to these characteristics, it is used to create the strongest roofing, fences, fixed formwork, heavy containers, workshops, garages, hangars and warehouses, etc. (cm. : " "). It is often used in the manufacture of fences, gates and gates, since the corrugated board marking, which contains the letter H, gives durability and increased strength to structures for various purposes.

The combination of the letters НС means that the buyer is offered a bearing-wall metal profile. This brand of products is classified as a universal type. The corrugation of such a profiled sheet has an average thickness and height. Structural-wall sheets can be used for slabs, roofing, wall cladding and more.

The letter C indicates that the corrugated board belongs to the wall category, which means the use of material for wall cladding. Most often, a heater is pre-laid under it. Despite the fact that the sheets have a small or medium thickness and height of the corrugation, the strength of this material makes it possible in some cases to use it to create roofs.

The letters in the marking are followed by numbers indicating the height of the corrugation on the sheet, expressed in millimeters. For example, C 8 is written on the profiled sheet, which means the material belongs to the wall type, and 8 is an eight-millimeter wave.

Metal profile parameters

When the consumer has an idea of \u200b\u200bwhat the parameters of the corrugated board are, then he can more easily decide on the choice of the products he needs, based on the purposes of its use.

The thickness of the profiled sheet is at least 0.4 millimeters (wall grade brands), and the maximum is 1.2 millimeters (for products of the carrier type).

Bearing metal sheets with the greatest thickness, which withstand increased loads, are used for arranging powerful floors between floors and in industrial workshops. The maximum weight of the corrugated board is 24 kilograms per "square", and the height of the corrugation can reach 114 millimeters, so it fits optimally. Additional ribs and grooves between the waves increase the resistance to stress.

Bearing-wall grades of corrugated board are versatile in use. is from 7 to 14.5 kilograms per "square" of material surface area. This indicator is average for the weight that has a corrugated board - the types of which are offered today on the building materials market. The same average is the thickness of the bearing-wall product, which is 0.5 - 0.8 millimeters. The same applies to the height of the corrugation wave - more than 8 millimeters. If an increased load on the surface of the material is not expected, then the profiled sheet of such parameters can be used for the roof.

Wall corrugated board is the lightest of all types, since its weight per square meter does not exceed 7 kilograms (for more details: ""). It is usually used for roofing and wall cladding. As the description of manufacturers testifies to the corrugated board, the thickness of the wall sheets is at least 0.4 mm, and the height of the corrugation is up to 8 mm. In the event that the roof coverage area is small and has steep slopes, this roofing option will be optimal. It will also be an excellent material for building fences or fences (more details: ""). This brand of corrugated board - the texture of which has a decent appearance, is often used in the construction of private households.

The most popular brands of metal profiles

Despite the huge range of products manufactured, there are the most popular brands of corrugated board.

Moreover, each specific type of product is used for specific purposes:

- N-60 - has a weight of 5 - 12 kg / m², the thickness of the profiled sheets is from 0.5 to 0.9 millimeters, the height of the corrugation is 6 centimeters. Used to create load-bearing structures and for roofing, often used in the construction of fences, fences, garages;

- N-75 - sheet weight - 9.2 - 12.0 kg / m², thickness - 0.7 - 1.0 millimeters, wave height - 7.5 centimeters. Refers to universal products used for various construction work. Performs not only bearing functions, but also protective ones. Such corrugated board is used for roofing and installation of floors;

- N-114 - weight 10.2 - 14.5 kg / m², sheet thickness from 0.7 - 1.2 millimeters, wave height - 11.4 centimeters. It has additional grooves to increase resistance to loads, the effective texture of the profiled sheet surface provides an attractive appearance. Designed to create the most durable structures and for other purposes;

- N-153 - such a brand of professional sheet is often called the European standard. Sheet weight - 10.3 - 21.5 kg / m², thickness - 0.7 - 1.5 millimeters, wave height - 15.3 centimeters. It is popular due to the ability to install on surfaces, the pitch of the crate for which is up to 9 meters;

- N-158 - a similar brand is popular due to the presence of the highest wave - 15.8 centimeters and the ability to use it on surfaces for which the crate is built in steps of up to 9 meters. The sheets have maximum rigidity and strength. This brand of profiled sheet is ideal for creating many types of structures.

Roofing metal profile - varieties of material "). A durable option is to cover their polyester, especially since it is presented on the market in a wide colors... The addition of Teflon to polyester makes the protective layer stronger. Coatings made of PVDF and a mixture of PVC and various additives are reliable.

Sheathing of external and internal surfaces with various sheet materials is a fairly popular finishing method. A metal profile of various configurations is used to create a strong frame on which plates, sheets or panels are attached. By creating flat and volumetric structures using a metal profile, walls, fences, roofs and ceilings are built.

Advantages of a metal profile

Despite the fact that to create a frame, you can use a wooden beam, plastic or shaped tube, specialists in repair and construction work prefer the metal profile.

This is due to the fact that the metal profile has the following positive properties:

- Immunity to temperature and humidity changes. The metal does not change its size and configuration under the influence of these factors.

- High strength and reliability. The various profiles are thick enough to withstand pressure or tensile forces. The presence of stiffeners only enhances the reliability of the products.

- Corrosion resistant. As a rule, iron products are coated with zinc or polymer spraying. This prevents them from rusting even in a humid environment. Aluminum moldings do not need additional finishing.

- Ecological cleanliness. Metal profiles do not stand out in environment harmful substances even under the influence of high temperatures caused by open flames.

- Ease of processing. In order to cut or bend the profile, the usual household tools that are in every home are enough: drills, hacksaws, grinders or metal shears.

- Durability. Quality products have a life span of decades.

- Affordable price. The metal profile is inexpensive building material, the cost of which has an insignificant share in the total estimate of repair and construction work.

For a metal profile, quite a lot of component parts have been created, with which you can create structures of any size and complexity.

Using steel and aluminum moldings, it is possible to install siding, PVC stretch fabric, drywall, plastic, MDF and other finishing materials.

High specifications metal profiles allow you to use it without restrictions, in almost any conditions.

Profile for drywall and siding

Drywall is one of the most popular finishing materials that can be used for sheathing both walls and ceilings. Certain brands of GKL are used for finishing fireplaces, showers and kitchens.

For this purpose, the following types of profile are used:

- Guide. These products serve as the basis for attaching rack or ceiling profiles. Parts have a U-shaped section. The length of one section is 300 cm or 400 cm.

- Ceiling. These products are intended to create a batten on which to screw finishing material... With a cross-section of 60 × 27 mm, they fit perfectly into the opening of the guide profile.

- Rack. A frame for walls and partitions is assembled from elements of this type. These products are secured in rails that are attached to the floor, ceiling and walls.

- Angular. Such details serve to strengthen the corners at the joints of the drywall sheets after fixing it to the frame.

- Beacon. These products are used for leveling concrete and brick walls plaster mortar.

It is impossible to make a frame from steel moldings without accessories that are used to fasten the profiles to the wall and to each other.

The following parts are used in the assembly of the steel frame:

- cross connectors;

- longitudinal connectors;

- corner connectors.

The connection of individual parts to each other is carried out with self-tapping screws. This provides a firm and secure fit.

Stretch ceiling baguettes

Stretch ceilings are the most presentable and practical option for finishing residential, utility and commercial premises. Baguettes for stretch fabrics are made of aluminum. This metal is strong enough to withstand the strong pressure that the tightly stretched PVC film appears.

According to the method of fastening, baguettes for stretch ceilings are divided into the following categories:

- Wall. These products are the most popular. The canvas is fixed at a distance of 5 cm or more from the floor slab.

- Ceiling. These moldings are fixed to the carrier board in cases where the wall material is not strong enough to withstand the tension of the canvas. The use of such profiles allows you to fix the film at a distance of 4-5 cm from the main ceiling.

- Universal. These baguettes can be mounted both on the ceiling and on the walls.

- Structural. These are complex products with the help of which steps, projections and recesses are created in multi-level stretch ceilings.

- Connecting. Profiles of this type are used to connect several canvases when decorating large areas.

If it is necessary to create a curved structure, triangular cuts are made in the profiles.

Polycarbonate profiles

Cellular polycarbonate is used to decorate awnings, gazebos, office and residential premises.

To create polycarbonate structures, aluminum profiles are used, such as:

- Connective. It is used for vertical tight joining of sheets.

- Ridge. Designed for joining polycarbonate panels on a gable roof.

- Wall mounted. It is used in cases where a polymer plastic roof is adjacent to a capital structure.

- End. This profile covers the lower edges of the polycarbonate sheets, protecting them from damage and giving the structure a finished look.

Since the aluminum surface is visible, it can have a different texture and color, created using a polymer coating.

Related entries:

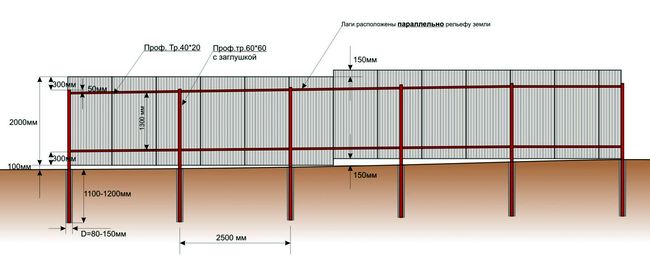

The most demanded structural material in private construction remains metallic profile... It is used in the construction of temporary structures, for fences, for the construction of ceilings and walls, for drywall and for siding, the scope of application of a metal profile is extremely wide, and today we will consider the features of using a square profile, prices and main characteristics.

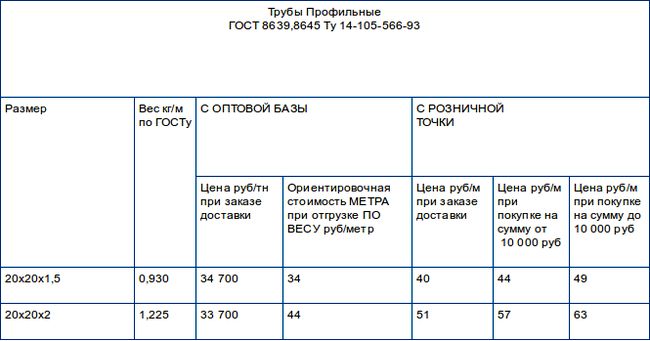

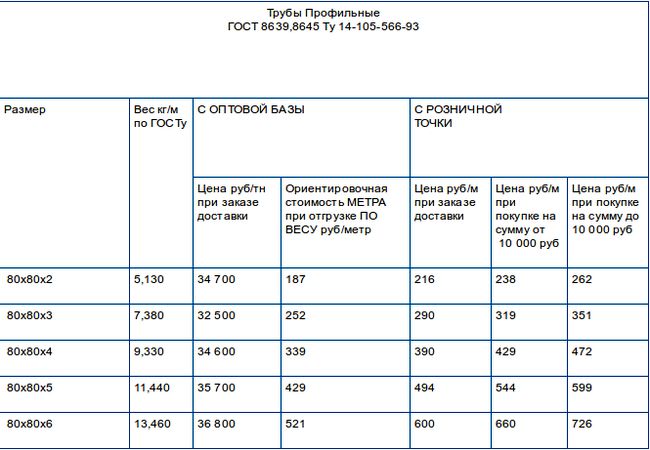

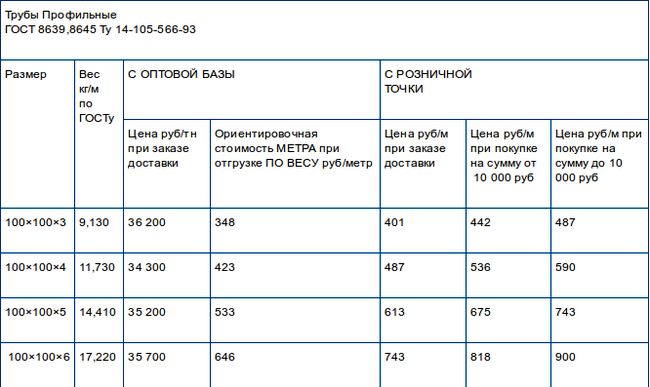

Types of metal profiles, price

Depending on the type of profile and the steel from which it is made, and in addition, on the manufacturing method, the price can be completely different and it is influenced not only by the size of the square. Below we have given approximate prices in Moscow for the summer of 2016 for several standard sizes. A square metal profile can be sold both by weight and by running meters, its price also depends on it.

In addition to a square profile, round pipes, a solid-rolled profile are also widely used, and a light galvanized profile of a complex shape for drywall and siding is especially popular. It is made from thin hot-rolled steel, and the range of special profiles for drywall is extremely wide. However, back to the square metal profile.

Scope of the square profile

The square profile is used in private construction for the construction of supports, columns, as reinforcement for concreting reinforced concrete structures, towers and towers. In addition, a certain standard size allows building frame house from a square profile, and such a variety of applications is determined by the ease of installation and fixation of other structural elements to the rental, simplifies welding. In some cases, a square profile can become an alternative to load-bearing beams - channels and I-beams, a corner.

In addition, the square profile is in high demand in agriculture for the construction of greenhouses and greenhouses, greenhouse complexes, structures for pets and for storing feed and fertilizers. When arranging a personal plot, it is also difficult to do without a square profile, since it is used not only for the construction of fences and fences, but also for light gazebos, awnings, gates and metal doors.

Advantages and disadvantages of shaped square pipes

The metal consumption of any structure greatly affects its final price and weight, and weight, in turn, can affect the structure of the foundation, for example. Just a square metal profile is able to reduce the metal consumption of any structure by 25%, while retaining the rigidity, strength and resistance to bending and torsion, comparable to those of a solid metal bar. Another plus of a square-shaped metal profile is that its rigidity can be adjusted not only by selecting the width of the side of the square, but also by the thickness of the wall.

Another good side of such a profile is that it is easier to store and transport - it takes up less space compared to round pipes, takes up the minimum volume during storage, which also affects the cost of transportation. It is also important that with anti-corrosion treatment or decorative painting, such profiles are simpler and more economical. A typical lack of profile square pipe - susceptibility to corrosion, since it is usually made of inexpensive ferrous metals. There are, of course, galvanized profiles, but the x price can double or even triple, depending on the thickness of the layer of anti-corrosion treatment.

Materials and technology for the production of a square profile

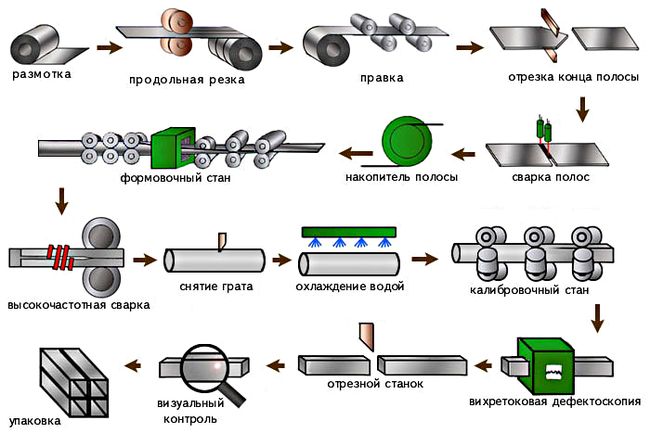

Typically, a profile square is made in one of two ways - welded or seamless. The most common profile is obtained with a steel seam. The production technology, its diagram, is shown in the figure, and the process includes several stages:

- Preparation of a semi-finished product, metal tape of a certain thickness, which will form the profile wall.

- A round profile is formed on a forming machine.

- The resulting seam is boiled with high-frequency currents.

- An intermediate check of the quality of the welded seam is carried out, the rejected products cannot be restored.

- Forming a square profile on a special rolling machine.

- Removal of internal stresses by temperature effects.

- Cutting the profile into measured pieces of the required length.

Seamless pipes are considered to be of higher quality, but also more expensive. They are made on special machines by drawing from an all-metal blank of a square profile.

Depending on the quality of the metal, the profile can be of class A or class B. In the first case, only the physical qualities of the metal and the linear dimensions of the profile are normalized for the profile, in the second - the chemical composition of the metal. The group B profile is commonly used in the chemical industry, as well as in the food industry and pharmacology.