We install frame sheathing structures for finishing works, how to choose a metal profile, what are the criteria for assessing the quality of a metal profile. What types of work is the metal profile used for?

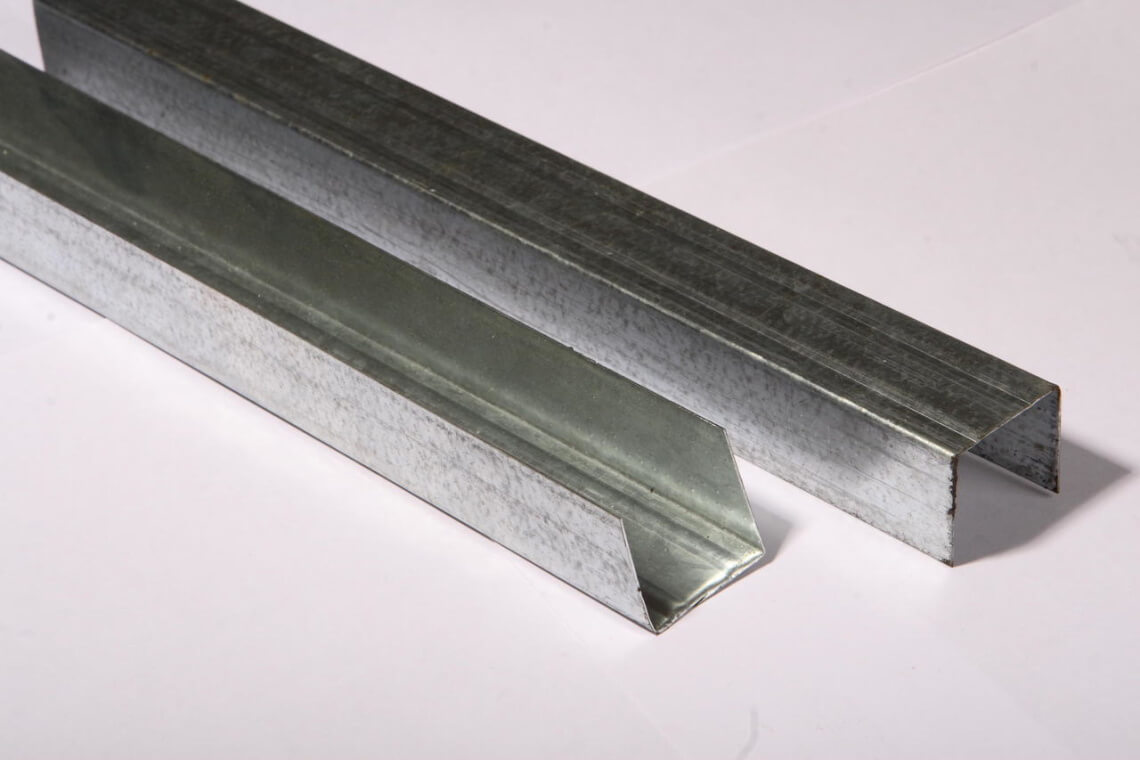

Probably the most demanded metal profile in rolled metal. It serves as the basis for the manufacture of metal frames, which are used in construction, usually for fixing drywall.

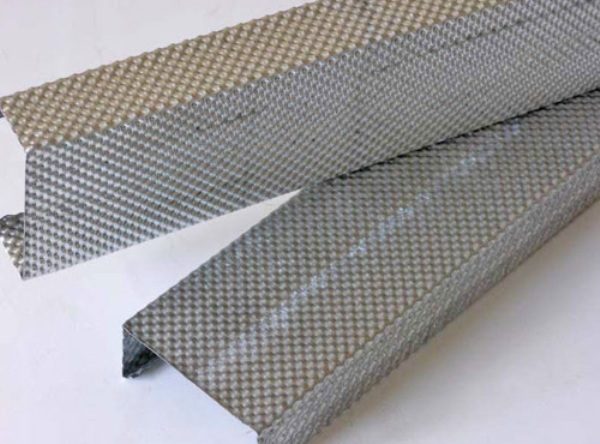

In order to prevent oxidation of the metal, the profile is produced with a galvanized coating.

The material for the metal profile is cold-rolled, galvanized or stainless steel and aluminum.

This basic structural element is popular for its low cost, reliability and good anti-corrosion properties.

The metal profile for fixing drywall is distinguished by its functional purpose, and it is presented in several types:

- rack-mount

- guiding

- ceiling

- ceiling guide

- angular

- arched

- beacon.

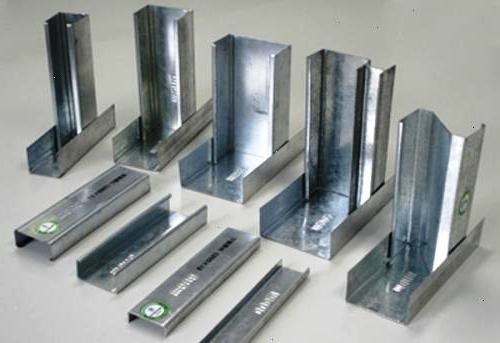

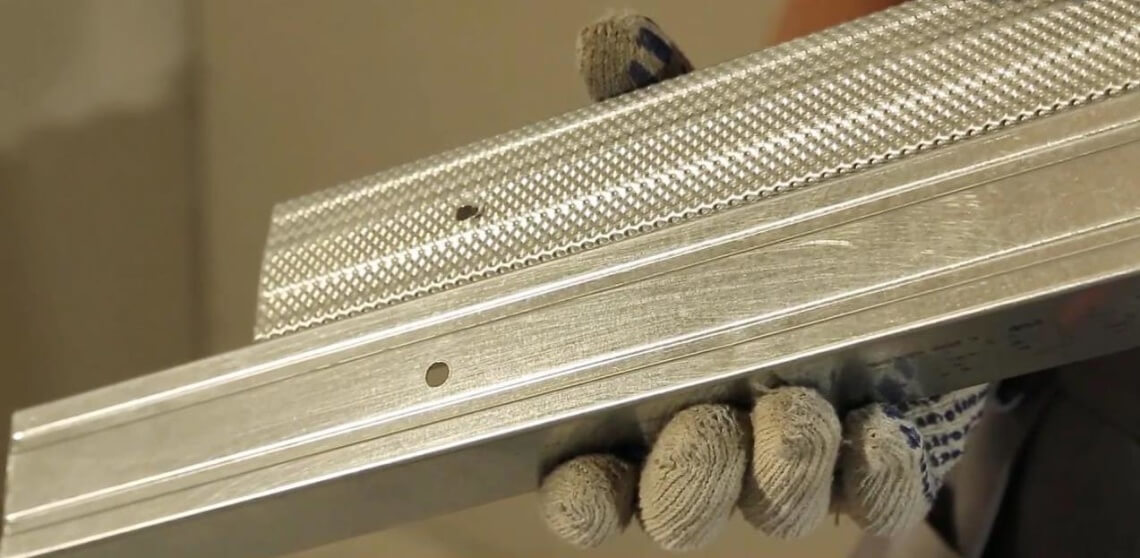

Rack profile with the designation PS or CW with a C-shaped sectionused for the manufacture of frames for drywall. This profile serves as a support for the frame elements. It is more rigid due to the longitudinal grooves in the profile flanges. The common lengths are 3,000 mm and 4,000 mm with a section of 50 * 50, 75 * 50, 100 * 50 mm.

The guide profile is designated as PN or UW and is used in conjunction with a rack profile, they must be of the same size, and they are used as jumpers for frame elements. Since this profile is the base profile for the rack, they must be the same length. This profile is a guide for the ceiling. Often the profile comes with holes for dowels, which speeds up the production of structural elements. If there are no holes for the dowels, you can make them yourself using a drill.

The ceiling profile is designated as PP or CD is one of the varieties of C-section profile and is used to fix suspended ceilings. Just like the rack-mount, this metal profile has grooves in the shelves and walls, which makes it more rigid. A combination of ceiling and guide profile is often used, which is defined as one of its varieties. The most common length of the ceiling profile is 3000 mm and 4000 mm with a section of 60 * 27 mm.

In order not to damage the corners of drywall structures, use metal corner profile.

The name itself arched metal profile suggests that it is used for the installation of curly structures. This metal profile has a different radius of flexibility and can be "turned out" both inward and outward, respectively, it is made outward or inward with shelves.

Beacon profile serves as a marker for plaster.

In addition to frames for installing drywall, metal profiles are also used in other installation and construction work - when laying communications, when installing ventilation and water supply systems. Installation of a roof in Ryazan will not do without the use of a metal profile.

In addition to the metal profile, in the manufacture of frames, various kinds of fasteners, anchors and connectors are used.

The most demanded structural material in private construction remains metallic profile... It is used in the construction of temporary structures, for fences, for the construction of ceilings and walls, for drywall and for siding, the scope of application of a metal profile is extremely wide, and today we will consider the features of using a square profile, prices and main characteristics.

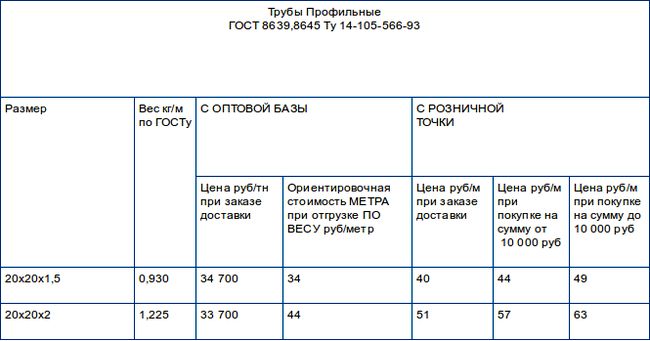

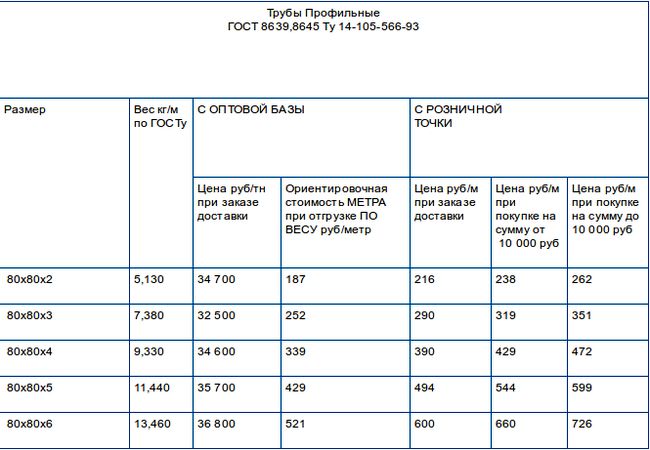

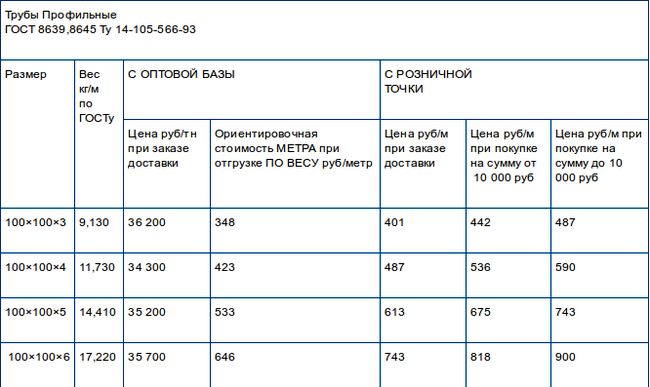

Types of metal profiles, price

Depending on the type of profile and the steel from which it is made, and in addition, on the manufacturing method, the price can be completely different and it is influenced not only by the size of the square. Below we have given approximate prices in Moscow for the summer of 2016 for several standard sizes. A square metal profile can be sold both by weight and by running meters, its price also depends on it.

In addition to a square profile, round pipes, a solid-rolled profile are also widely used, and a light galvanized profile of a complex shape for drywall and siding is especially popular. It is made from thin hot-rolled steel, and the range of special profiles for drywall is extremely wide. However, let's get back to the square metal profile.

Scope of the square profile

The square profile is used in private construction for the construction of supports, columns, as reinforcement for concreting reinforced concrete structures, towers and towers. In addition, a certain standard size allows building frame house from a square profile, and such a variety of applications is determined by the ease of installation and fixation of other structural elements to the rental, simplifies welding. In some cases, a square profile can become an alternative to load-bearing beams - channels and I-beams, a corner.

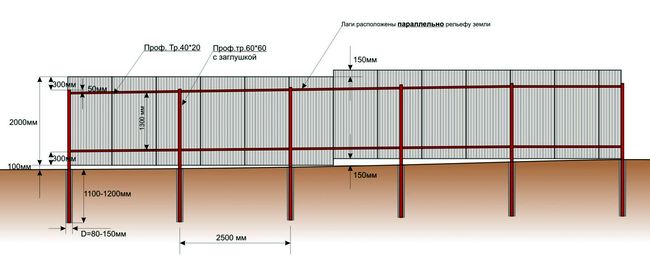

In addition, the square profile is in high demand in agriculture for the construction of greenhouses and greenhouses, greenhouse complexes, structures for pets and for storing feed and fertilizers. When arranging a personal plot, it is also difficult to do without a square profile, since it is used not only for the construction of fences and fences, but also for light gazebos, awnings, gates and metal doors.

Advantages and disadvantages of shaped square pipes

The metal consumption of any structure greatly affects its final price and weight, and weight, in turn, can affect the structure of the foundation, for example. Just a square metal profile is able to reduce the metal consumption of any structure by 25%, while retaining the rigidity, strength and resistance to bending and torsion, comparable to those of a solid metal bar. Another plus of a square-shaped metal profile is that its rigidity can be adjusted not only by selecting the width of the side of the square, but also by the thickness of the wall.

Another good side of such a profile is that it is easier to store and transport - it takes up less space compared to round pipes, takes up the minimum volume during storage, which also affects the cost of transportation. It is also important that with anti-corrosion treatment or decorative painting, such profiles are simpler and more economical. A typical lack of profile square pipe - susceptibility to corrosion, since it is usually made of inexpensive ferrous metals. There are, of course, galvanized profiles, but the x price can double, or even triple, depending on the thickness of the layer of anti-corrosion treatment.

Materials and technology for the production of a square profile

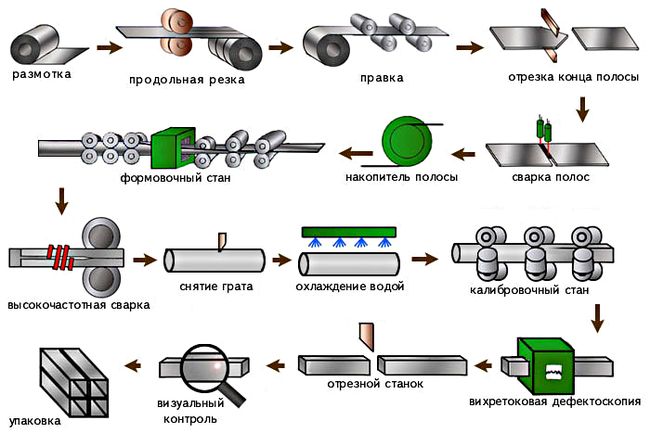

Typically, a profile square is made in one of two ways - welded or seamless. The most common profile is obtained with a steel seam. The production technology, its diagram, is shown in the figure, and the process includes several stages:

- Preparation of a semi-finished product, metal tape of a certain thickness, which will form the profile wall.

- A round profile is formed on a forming machine.

- The resulting seam is boiled with high-frequency currents.

- An intermediate check of the quality of the welded seam is carried out, the rejected products cannot be restored.

- Forming a square profile on a special rolling machine.

- Removal of internal stresses by temperature effects.

- Cutting the profile into measured pieces of the required length.

Seamless pipes are considered to be of higher quality, but also more expensive. They are made on special machines by drawing from an all-metal blank of a square profile.

Depending on the quality of the metal, the profile can be of class A or class B. In the first case, only the physical qualities of the metal and the linear dimensions of the profile are normalized for the profile, in the second - the chemical composition of the metal. The group B profile is commonly used in the chemical industry, as well as in the food industry and pharmacology.

The method of gluing drywall sheets to the base is considered the simplest. But in the case of the construction of the frame, there are many nuances and details.

The main structural details of such a frame are metal profiles for drywall. Moreover, the range of these products is very extensive, and each component has a special role. Therefore, in this article we will look at the types of parts required to install frames, and fasteners for them.

Place of fixation

Before purchasing material, find out:

- the purpose of the parts;

- required dimensions;

- the specifics of the use of certain parts in each specific situation.

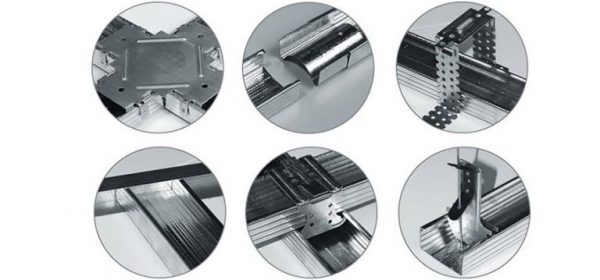

For the construction of the frame, connecting elements will also be required. Without them, installation of any structure is impossible, and not only on the basis of drywall.

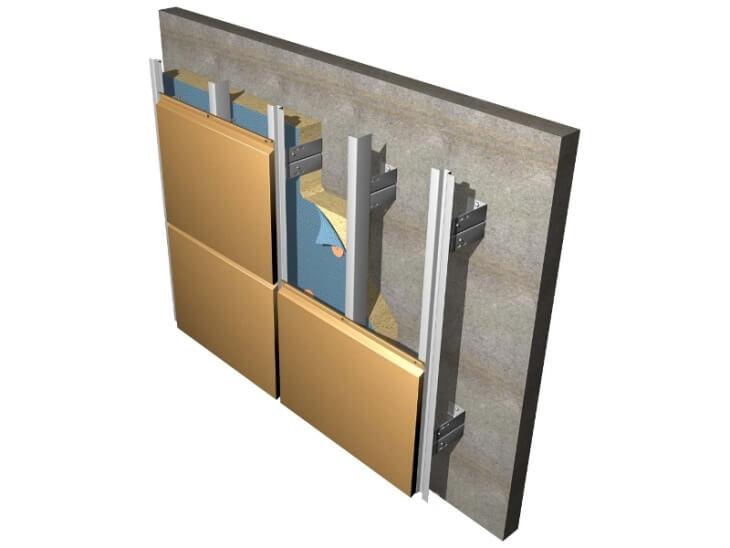

Installation work on the assembly of the frame for the organization of drywall structures is carried out on the basis of two types of profiles. Some are intended for cladding work when finishing individual planes, others are used for the construction of partitions.

Sheathing parts are used for mounting sheets on a prepared surface. With their help, ceilings and walls are processed.

The main types of cladding materials:

- arched.

The profile marked as UD is designed to form a plane on the surface to be plated. If there is a need for the construction of a frame base in order to sheathe the wall with plasterboard, this type is used. It is placed around the perimeter. The dimensions are 2.5 cm in width and 3 meters in length.

UD is one of the main elements

UD is one of the main elements Construction reliability

As for the reliability criteria, in this case they are determined by the thickness of the metal from which they are made. This means that with increasing steel thickness, the level of strength and reliability of the product increases. The possibilities of application are also increasing.

For example, a thin material made of steel is used only in cladding work when processing walls. Reliable products, the raw material for the manufacture of which was thin sheet steel, already have more extensive capabilities and are used for the construction of structures with a ceiling type of placement.

Profile marked CD - carrying. Products of this type are used to form a metal base. They bear a greater volume of loads, since these parts hold the weight of the drywall sheets. The CD type gives the frame base reliability and rigidity.

Bearing profiles are similar in material characteristics to UD belts. The strength and effectiveness of the product depends on the thickness of the steel.

The thinner the material, the lower the profile strength. This ultimately affects the volume of fasteners installed.

The whole structure is held on the CD

The whole structure is held on the CD CD product sizes vary. Their width is 6 cm, their thickness is 2.5 cm.The length is 3 or 4 m.

The arched version is a kind of embodiment of the properties of both types of products. It is distinguished from the bearing or guide profile by its design features. The element is weakened by special cuts and holes. This is done with the expectation that the part will be bent into a smooth arc. The dimensions completely repeat the parameters of the rigid options presented earlier.

Products for partitions

Unlike cladding products, the dimensions of profiles for the construction of plasterboard partitions are much larger. This is due to the other purpose of these elements.

Dimensions in width:

- 5 cm;

- 7.5 cm;

- 10 cm;

- 12.5 cm;

- 15 cm.

The profile for the installation of drywall is selected taking into account technical characteristics partitions.

The choice of the product is influenced by:

- sound insulation indicator;

- the presence of large elements of communication systems that need to be hidden;

- thermal insulation index.

Guides of this type with UW markings are used to form the plane of the wall and its direction. Installation is carried out along the perimeter of the wall.

Arched profile

Arched profile The frame parts are mounted on the ceiling, floor or walls.

Plasterboard posts are marked with the letters CW. They are used to strengthen the basis of the frame structure, to endow it with increased strength characteristics. Installation of such an element is carried out in increments of 40 cm. This will allow you to attach a couple of sheets of drywall on the sides.

Characteristics of fasteners

In addition to profiles, the construction of the frame involves other details, for example, fasteners, which act as a connecting element that reliably holds the components of the structure together.

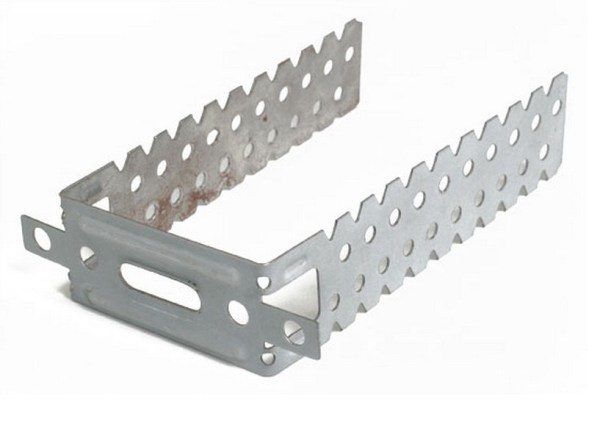

Bracket

Bracket The most common option is a metal bracket that has U-shape... It looks like a plate covered with perforations. This plate is folded if desired. The purpose of this type of fastener is the same - to connect existing stationary walls and ceiling with a metal frame structure. The middle of the fastener is fixed to the plane to be sheathed, and the bendable ends are fixed to the supporting profile with self-tapping screws.

A fast suspension is used as a substitute. Most often, such fasteners are used when the U-shaped bracket is not large enough to ensure a reliable connection of parts.

Fast suspension is a two-piece mechanism. The first component is the suspension, which is fixed in the CD-element of the frame. The second is a knitting needle with an eyelet, which is connected to the suspension using a spring. Such a mechanism has the advantage - during the installation process, the position of the fasteners is easily adjusted. For this, the spring is pressed with a finger.

The quick suspension also has a drawback. During operation, the spring loses its elasticity, the ceiling sags. Therefore, this type of fastener is rarely used for these purposes.

Using a metal profile

Using a metal profile  Metal profiles are used not only for internal works

Metal profiles are used not only for internal works

Profile elements

Profile elements  The strength and reliability of the fastening are guaranteed

The strength and reliability of the fastening are guaranteed  Any work can be done if you use a metal profile during construction

Any work can be done if you use a metal profile during construction In contact with

Today, steel profiles are the basis of most building technologies... Its use is necessary when creating various load-bearing structures, since it is the steel profile that has a whole range of advantages over stone and reinforced concrete. The metal profile is characterized by high strength and reliability. At the same time, it is lighter and with smaller dimensions.

Most often, a steel profile is used in a structure working in tension and bending, less often in compression. Their production is carried out using welded, bolted and riveted joints. Steel structures include the following types profile:

- bent (welded, seamless);

- welded;

- rolled;

- stamped.

The price per meter of a metal steel profile of a square, rectangular cross-section depends not only on the quality and properties of the material, but also on the production technology. These factors also determine the set of performance characteristics that the finished product will have. Thus, a bent metal profile differs from a stamped or hot-rolled profile by a more rational distribution of metal along the length and the entire section of the product. This means that it has more reliable performance properties at a low cost.

Benefits of using a metal profile

You can buy a steel profile for various construction purposes. One of the main advantages of its use is the ability to assemble large objects from modular blocks manufactured at the manufacturing plant. This allows:

- increase the construction speed;

- reduce metal consumption;

- reduce the cost of construction and installation work.

Cold-formed profiles, which are made from galvanized steel sheets, have increased rigidity and resistance to corrosion, which ensures their effective operation for 25 years. In the company "MetalHolding" you can inexpensively buy a metal profile in Moscow at the best cost.

Metal profiles are used to create frames for various designs. Most often these are suspended ceilings, facing surfaces, etc. In turn, this type of rolled metal is a rigid base for mounting drywall sheets. The production of profiles is carried out by cold rolling a thin steel strip on special equipment... This ensures high strength and good performance. As anti-corrosion protection of elements, it is customary to use galvanized raw material. The small profile thickness makes it easy to handle with hand tools.

For any siding and its installation, additional fasteners are used. One of these is a metal profile, thanks to which the cladding is attached to the wall of the house. All types of profiles come with standard parameters, but are used for different purposes. As a young and inexperienced in construction and renovation work, I repeatedly purchased additional materials for the wrong purpose. Therefore, now, when I have independently completed both internal and external facing work, I want to tell you about the types of these materials, their area of \u200b\u200bapplication and about fastening the profile to the walls of the building.

More about them

Everyone knows that the facade serves not only as a beautiful cladding of the house, but also performs very important functions, such as sound and heat insulation. For a correct and long service life of the facade, it is necessary to select the right fittings and install the cladding without gaps. That is why fixing the profile to the wall surface is not the whole job. It is necessary to correctly calculate the installation locations of the frame, so that in the future no joining of the panels does not form.

Additional elements for siding cladding are a whole set of metal profiles. It includes the following types:

- To begin with, a start profile is used. It is the beginning and support for the installation of the lower row of cladding. The starter element serves as a guide, the profile is attached to the surface without unnecessary efforts.

- A corner element is used for finishing the corners of the building.

- To arrange the inner corners, use the J-profile.

- Window fittings close the door and window slopes.

- Docking requires a H-shaped bar

- The edges of the last panels are masked with a finishing strip.

Important! The metal profile is even used to install fences. One of these is the hat profile 50x20x3000, where 3000 is its length (3m), and 50x20 is the hat-type section. There are two types: painted and galvanized, for the first steel thickness is 1.5 mm, for the second - 1.2 mm.

When I came across a large number of types of additional elements, I realized that before starting repair work, you need to calculate the amount of material required. Agree, it will be a shame if you start work and find that you lack profiles or do not need any at all.

Table standard sizes metal panels

| Name | The size | Metal thickness |

| U-shaped | 50x22x20 mm, 65x22x20 mm, 80x22x20 mm, 100x22x20 mm | 1.2 mm |

| L-shaped | 40x40 mm, 50x50 mm, 44x60 mm | 1.2 mm |

| Z-shaped | 40x22x20 mm, 30x22x20 mm, 50x22x20 mm | 1.2mm, 1.5mm |

| T-shaped | 65x30 mm, 80x30 mm | 1.2 mm |

The standard length of all profiles is 3 meters, but it is possible to manufacture according to individual sketches up to 6 meters. It is also possible to prime metal strips or paint them in the desired color. When I chose the additional strips I needed, I immediately asked them to give them the color I needed. This can of course be avoided if you buy materials in standard sizes, but I had to order custom production.

Installing the elements

The metal profile serves as the basis for the manufacture of metal frames

Since the beginning pvc installations slabs starts from the bottom, then the starting profile is attached to the surface at the bottom of the crate. The plank width depends on the width pvc panels and later she hides under them. We fix the profile to the surface with self-tapping screws with a wide head - thanks to this, any types of PVC plates will firmly cling to the wall. The color of the starting strip does not matter, because it will hide under the PVC cladding. But thanks to the corner components, the siding joints are designed at the corners of the house. Together with them, the side of the pvc panels is correctly fixed and the correct angle is formed. The use of these corners gives integrity to the entire structure on the wall. J-bevels are used for finishing the cornice and balcony. Same metal J-profile covers the side ends of ordinary pvc boards.

All types of profiles are important for finishing work, with their help, any structure is not only firmly attached to the wall, but also takes on a complete look.

To securely connect the siding panels, H-planks are used, they fasten the edges of the slabs along the entire length. And the U-profile serves as an edging when installing siding, its plasticity allows the use of strips to obtain a structure of any shape.

A little about the I-beam

Those who like to solve a crossword puzzle have probably come across this word more than once. I think that an ignorant person would never have been able to imagine that an I-beam is a profile of a bearing beam. Such beams are often used to build bridges. I-beams provide an economical support option and reduce the overall weight of the structure. Externally, the profile is similar to the letter H, but with the peculiarity of choosing the desired size of the wall and shelf.