Slopes on the outside of the window. How to finish window slopes with your own hands

Finishing window slopes indoors - one of the types of mandatory finishing works, which are designed to create reliable insulation of the window system from impact environment... In order for it to be used for a long time and with high quality, you can finish it yourself with one of the modern materials.

The improvement of the apartment does not stop only with the installation of a new window. During installation, the window opening is partially destroyed. To eliminate all the chips that have appeared in the walls, to extend the life of the window system, you will need to finish the slopes in your own house. If desired, you can do it yourself.

Now it is fashionable to live or spend a summer vacation in an environmentally friendly wooden house... In such a dwelling, it is realistic to install both plastic and wooden windows... In a wooden house for internal and exterior decoration use wooden lining, natural wood or practical plastic.

For plastic windows installed in a wooden house, experts advise choosing plastic panels... To independently carry out finishing with plastic panels in your favorite wooden house, you will need the material itself, corners, sealant, a reliable screwdriver, and a special construction stapler with staples.

In a wooden house, built of logs, window decoration with lining is relevant. It is environmentally friendly, strong, durable, frost-resistant. For this kind of finishing in a wooden house with your own hands, prepare a screwdriver, the right amount of material, sealant, screws and corners.

A starter set of tools and materials for finishing with any of the materials, which will be discussed below, includes a painting knife, fleas and profiles (for the frame method), a screwdriver, a perforator (for a frameless method), putty, gypsum plasterboard, level, screws, spatula, container for glue, serpyanka, perforated corner, acrylic, construction gun.

Finishing

Anyone who wants to do the decoration with their own hands is advised to warm the slopes first. When choosing plaster slopes, paint can be used as a finishing layer. Drywall sheets should be attached to the metal base with self-tapping screws; corners should be reinforced with slats. For all types of slopes, you only need to adhere to the expanded angle, do not leave an untreated foam seam outside.

Plaster

Previously, the window opening is freed from old plaster, polyurethane foam, covered with a primer, and metal profiles are installed. For plastering, a dry mixture based on gypsum or cement is diluted with a liquid and placed on the base by spraying, then there is a soil and a cover. The plaster is sanded and sanded, stained.

When carrying out such a decoration with your own hands, you cannot keep the window open. Otherwise, the solution will fall into the cracks of the fittings and then interfere with its normal operation.

The advantage of the method is considered to be low cost; the disadvantages include a large amount of dirt.

Plasterboard

Plasterboarding the slopes is a good and not time-consuming method. Sheets are attached to a special glue if the walls and slopes are not curved. But professionals advise to pre-install a frame consisting of metal profiles, cut according to the dimensions of the slopes.

Take care of good heat and sound insulation. There can be no voids in the space between the wall and the cladding. They should be filled with special polyurethane foam, and mineral wool or foam is placed under the sheets with their own hands. Next, putty is carried out, grinding and painting of the resulting structure. Where drywall is placed in the window profiles, it is advised to glue the mesh tape. This is followed by 2 layers of putty, grouting, painting with acrylic or oil paint.

Bear in mind that moisture resistant drywall boasts an increased level of rigidity, excellent thermal insulation and high thermal resistance.

Plastic

A universal option recognized plastic slopes... Plastic can last 15 years or more. Unlike plaster, it is permissible to make slopes from this material on the day when the window was installed. PVC panels create thermal insulation, have good moisture resistance, rigidity, durability, do not sweat, do not lose their primary color, they are easy to wash. In such panels, there is no excess voltage if changes in temperature are observed. Window openings have a presentable look. For insulation in such structures, mineral wool is used.

Plastic became popular wall panels and sandwich panels. The second type of panels is 2 sheets of plastic with a layer of extruded or expanded polystyrene placed between them. Manufacturers offer such panels with a thickness of 8 to 36 mm. For window cladding, it is better to take those whose thickness is 1 cm. You can use this material to finish the slopes of window systems with a width of 5 - 150 cm. The disadvantage is that when exposed to moisture, delamination of such material is not excluded.

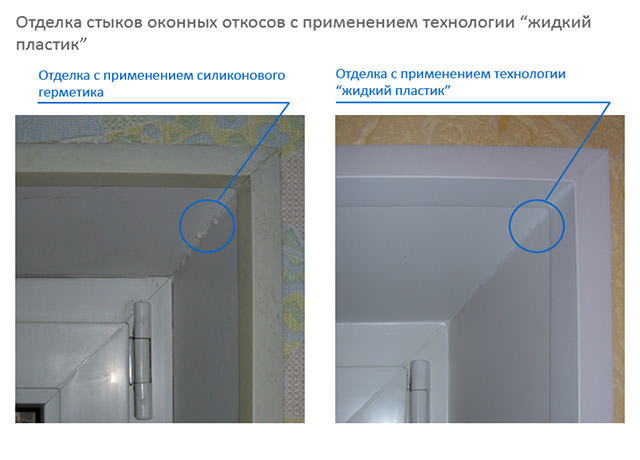

Before mounting the panels, the foam is allowed to dry for 1 day. The installation is carried out simultaneously with the windowsills. The ends of the materials are fixed with dowels to the base of the slope, fasteners and decorative corners made of plastic are installed. Seams are treated with PVC-based glue or neutral sealant. It does not have a sticky consistency, so it will not turn yellow or get dirty.

Decorative stone

The decoration of the slopes, which is performed by many beloved decorative stone, also called artificial brick, perfectly imitates natural material... Cladding artificial stone much lighter and cheaper than natural marble, granite or onyx. Gypsum or cement are the main components of any decorative stone, as well as fillers (expanded clay, pumice, perlite) and dyes. The stone is often like a brick. There are options for decorating slopes with chipped or sawn decorative stone.

For finishing with a stone inside the premises, specimens 1.5 - 2 cm thick are selected. Such an artificial brick must be laid with your own hands in strictly horizontal stripes and fixed to the surface with liquid nails. If the main component of the decorative stone is gypsum, you can actually trim it with a hacksaw, and if the cement - only with an electric circular saw. At the end of the facing of the slopes with a stone, the joints must be rubbed. After waiting a day, they are treated with a special solution and smoothed using a rubber spatula. It is permissible to lay artificial bricks using butt technology without seams.

No less popular is the decoration of slopes with tiles, ceramic or tiles imitating natural stone.

![]()

Advantages of finishing with any tile:

- excellent appearance,

- a wide range of colors and textures,

- ease of maintenance, resistance to damage,

- strength and long service life,

- additional retention window frame.

The disadvantages include the high cost of tiling and the complexity of its installation for beginners.

It is easy to finish with textured tiles with minimal theoretical knowledge with your own hands, since you do not need to make the surface even. The step-by-step technology for performing work looks like this:

- place marks on the surface;

- prime the slopes;

- apply glue (it is permissible to take liquid nails or sealant);

- glue the tiles horizontally;

- use corner pieces to avoid overlapping tiles on outer corners.

Nothing decorates a window like well-executed slopes. At first glance, decorating window slopes with your own hands is just a solvable task. In fact, this is not the case. Before starting work, it is imperative to study the technology and then skillfully apply it, since the correct slopes are not only the finished view of the window, but also an important technical point. So, let's take a closer look at what "these slopes are such an animal, and what they eat it with."

Of course, a common man in the street may immediately have a question: "Are they really necessary?" Without interior decoration the process of installing PVC windows is considered incomplete, since the main task of the slopes is to protect the mounting foam filling the gap between the wall and the frame from the influence of external factors. This material will serve you for a long time only in the absence of exposure to air and sunlight.

The consequence of the absence of slopes inside or their illiterate installation are:

- the appearance of black mold due to high humidity on the slopes;

- drafts in the apartment;

- fogging of windows and their rapid wear.

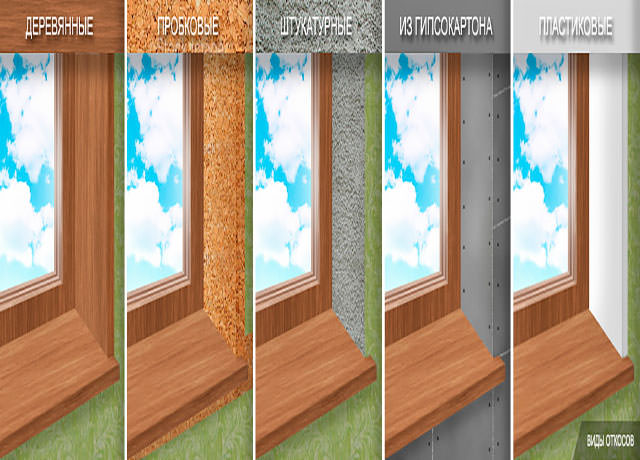

There are several types of materials for interior decoration of windows. We will present them below.

Methods for finishing slopes

Surely, in almost any city in our country you can find firms offering services for installing window slopes inside, but, frankly, this procedure is not cheap. In this regard, a significant savings for the family budget will be the choice in favor of DIY finishing. Decorating the slopes of windows with plastic, although it seems a difficult and overwhelming business, but in the right hands, everything goes well.

Before starting finishing work, a preparatory stage should be carried out: removing dust and old paint (if any) and impregnating the walls with an antiseptic primer.

The surface has been prepared, and now we will consider what types of finishing the window slopes exist:

- plastering;

- plasterboard finishing;

- plastic finish.

Let's see what the essence of each method is.

Plastering of slopes

The method of finishing the internal slopes with plaster was very popular at one time. This option is suitable for execution in brick, monolith and stone houses. For wooden buildings, other methods will be more suitable.

In areas where severe frosts in winter are possible, the use of modern heat-insulating plaster will be relevant. This mixture prevents the slopes from freezing.

Stages of doing plastered slopes with your own hands:

- applying plaster mixture on slopes in several layers. Important: the next layer is smeared only after the previous one has completely dried. Plastering lasts one to two weeks;

- foaming gaps;

- surface primer;

- filling and painting of slopes.

The method of finishing slopes using plaster compounds has a number of serious disadvantages that outweigh the positive qualities of the method. These include:

- inconvenience and laboriousness of the procedure;

- the high cost of the materials used (cheap mixtures eventually lead to the passage of cold air through the window);

- the formation of tears due to the difference in the properties of the plaster mixture and the plastic of the window;

- fogging of windows due to the lack of the required thermal insulation.

Plus, for correct execution this job requires professional skill.

Due to the above disadvantages of finishing the slopes with plaster, some experts do not even recommend considering this method as a do-it-yourself finishing option.

Plasterboard slopes

The use of drywall for windows inside is a transitional option for finishing in terms of quality and cost of work.

There are three options for attaching drywall to the surface of the openings:

- metal profile;

- adhesive mixtures;

- polyurethane foam.

Most often, a metal profile is used, since its installation is simple, and the structure is very durable. They work with foam when the use of the previous options is irrational. For example, there is nowhere to attach a metal profile, or there is no possibility of applying glue to the surface of the opening. Newbies in the decoration of slopes often work with glue mixtures.

Installing drywall slopes with your own hands using metal profile includes:

- attachment along the border of the frame of the L-shaped profile (base for drywall);

- covering the profile with a sealant;

- filling the space between the opening and the slope with stone wool;

- gluing drywall;

- sealing gaps with sealant;

- putty and decorating of slopes (painting, applying decorative plaster or a film that simulates various textures).

Among the advantages of drywall slopes are: long service life, smooth and aesthetic appearance, excellent thermal insulation qualities.

The downside of this material is that it is afraid of moisture. In this regard, plasterboard slopes are not installed in rooms with high humidity.

Decorating slopes with plastic

The use of plastic panels for finishing window openings is a fairly common, modern method. The use of plastic helps to achieve a completely straight surface, superior in quality to drywall and does not require decorating. Such slopes do not need periodic repairs at all. Simple maintenance includes only cleaning from dust and dirt with a damp cloth.

Let's consider what materials are available on the market for this method.

Plastic panels

The method of finishing windows with plastic clapboard is very popular. It is attached to the opening with mounting foam, which does not require the use of special tools, and this is an absolute plus of the method. But, as in the version with plaster, it will not be easy for a person without special skills to achieve the perfect result. The work time is about three hours for one opening.

PVC panels

PVC panels are a composition of plastic sheets, connected by stiffening ribs, in the gap between which there is free space.

Specialized PVC slope systems are now sold in stores. Their parts are purposefully manufactured taking into account the parameters of both conventional and non-standard window openings. Therefore, almost everyone can do window cladding with their own hands using this method. The only drawback of ready-made PVC systems is the high cost.

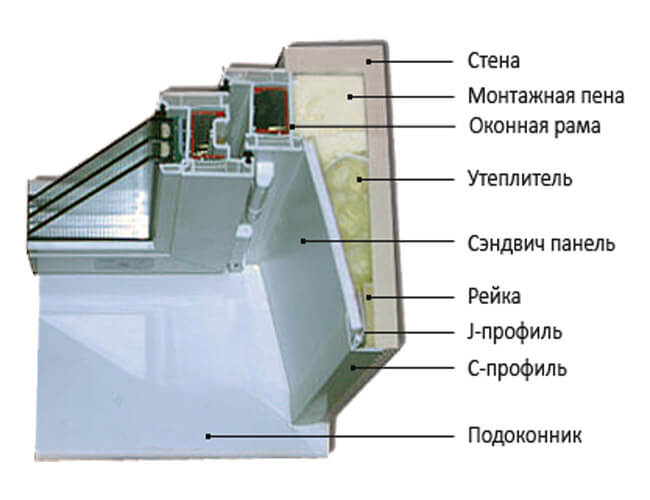

Sandwich panels

In contrast to simple PVC panels, sandwich panels have a structure consisting of three layers of plastic, between two of them there is an insulating material. Polyurethane foam is often used as a heater, which meets all safety and environmental parameters.

Among the advantages of sandwich panels, it can be noted that when installing them, there is no need to insulate slopes, because these panels have remarkable thermal insulation properties. But these panels are also imperfect and can delaminate when exposed to humid air.

Decorating window slopes with plastic panels is a popular and versatile method. Such slopes:

- you can quickly do it yourself;

- under the influence of sunlight, they do not change color and do not deform;

- just wash;

- resistant to static electricity and other negative factors;

- look quite presentable (you can very easily choose a material that matches the color of the window frame).

Facing slopes with PVC panels is carried out without unnecessary actions: puttying and painting. They have a good ability to keep out steam.

The resistance of the PVC panel material to temperature extremes within ± 20 degrees Celsius is another positive quality of such slopes.

Consider how the basic steps are followed for facing slopes with plastic panels.

Stages of facing window openings with PVC panels with your own hands

Before proceeding with the very facing of the slopes, it is necessary to clean the surface of debris and remove the protruding sections of the polyurethane foam. Next, the walls must be treated with antifungal agents.

Frame fabrication

Along the entire border of the window opening, wooden bars 0.8-1 cm thick, 2.5-3 cm wide are nailed. To secure them, self-tapping screws 9.5 cm are used. The bars are placed so that they do not go beyond the edge of the wall. The bars are fixed vertically, aligning with the building level, so that the slopes are completely flat. Note that when choosing bars for the frame, they must pay attention to the quality of the product and material. The wood should be dry and not damaged by pests, and the bars themselves should be even and smooth and without blue, which is an indicator of the beginning of decay of the material.

PVC panels have sufficient rigidity, which does not allow them to mask small gaps at the junction of the window frame to the opening. These gaps in the future may be the cause of drafts in the apartment. To avoid this, during the facing of the slopes, a heater is laid between the surface of the opening and the panels. The following materials are used as thermal insulating material: Isolone, expanded polystyrene or stone wool. It is important to lay the insulation in such a way that its thickness does not exceed the thickness of the frame bars. Fix it with glue.

Using 4.5 mm self-tapping screws, a U-shaped plastic profile is attached along the border of the window junction to the wall of the opening. In the future, it will be inserted into it PVC panel... The side elements are fixed directly to the frame. The lower horizontal section of the profile is fixed directly to the surface of the opening, the upper one is fixed with one edge on the bar, and the other edge is inserted into the groove of the vertical profile. In the places of abutment of the sections of the U-shaped frame, the corners are slightly cut off with a knife to make a neat joint.

The F-shaped profile is fixed on the outer border of the window opening so that its wide part is on the front side (the fastening resembles a corner). This element is attached to the wall using liquid nails. Excess F-shaped profile is cut off after joining. Note that this element of the slope structure hides the uneven cut of the wallpaper around the perimeter of the window opening. The F-profile is fixed only after the PVC panels are inserted into the grooves of the frame (the grooves are partially filled with acrylic sealant beforehand).

Installation of PVC panels

Front installation of PVC panels in the frame as accurately as possible measure the length and width of the slope. If the width of the plastic is greater than the vertically located opening, then the excess part is cut off using a clerical knife. After installing the plastic, the joints are "refined": they are rubbed with white silicone or, with the help of liquid plastic, they are closed with a polyvinyl chloride corner, matching the color of the panels.

So, we reviewed all possible ways internal facing of slopes. By the combination of the advantages and disadvantages, the time of the procedure, the durability of the result, most experts agree that PVC panels are the best material for finishing window openings with their own hands. But the choice suitable optionno doubt belongs to the performer. Level to help you!

I welcome everyone! Today we will discuss an interesting topic for everyone, the decoration of internal slopes with plastic. This is especially interesting for those who have just installed new windows for themselves.

After installing windows in my house, I had the same question: "How to decorate the internal slopes?" There are many finishing methods.

One method is to plaster the slopes. But this method has many disadvantages: over time, they crack, sometimes freeze, mold may appear. Also, plastering slopes takes a lot of time and is very dusty.

I did not want to finish the slopes with plaster and found another way - plastic finishing. This method is faster and less dusty, more reliable. It also provides us with a choice of colors and patterns that we can choose to match the design of the room. Plastic is durable, unlike plaster.

For myself, I definitely found a reliable way of finishing - this is plastic finishing. I want to tell you about how to do it correctly and avoid any mistakes in this article.

Slopes for plastic windows. Choosing a method of finishing window slopes: my practical experience

Today I would like to talk about what methods of finishing slopes for plastic windows exist. I will describe to you the pros and cons of this or that method, I will give you some important tips, and also tell you about which window slopes I chose.

More recently, many of our fellow citizens preferred to finish the old fashioned way plastic windows plaster slopes. Now it has become quite obvious that this method has a number of serious drawbacks. The plaster mix does not have a reliable connection with the PVC frame, which ultimately leads to the appearance of gaps between the surfaces of the slope and the frame.

Due to the peculiarities of the composition and the material used, cracks appear on the surface of the slopes. This is facilitated by seasonal changes in air temperature. At low temperatures, there is a possibility of freezing of the slope due to the weak heat-insulating properties of the plaster, which leads to the formation of condensation and mold.

Another disadvantage of plaster slopes is the long duration of the work performed. After all, the plaster is applied in several layers, and it takes up to 5 hours for each layer to dry. Also, this method is characterized by high pollution, high labor intensity and, accordingly, high cost. Conclusion: this method is one of the most undesirable.

Slopes on windows made of panelite - cellular plastic

The disadvantages of this method are that the color of the panel changes over time. This becomes especially noticeable on the face of the stiffener. In addition, the maximum width of cellular plastic is 25 centimeters. And, if the depth of the sealed opening is more than 25 centimeters, then the panels have to be joined together. And this leads to a clear deterioration in the appearance of the slopes.

Glue slope

This is when thin plastic is glued to the surface of the slope. For all its simplicity this way has serious disadvantages. Namely, unreliability due to thermal expansion or contraction of the material used. And, as a result, plastic flaking. Moreover, the formation of condensation, and freezing of slopes, since they are not insulated due to the specifics of this method.

Since this article discusses the finishing of window slopes in all existing ways, one cannot fail to mention this. Thin plastic is glued to a drywall sheet. The disadvantages are not a particular reliability of the adhesive connection with a high labor intensity of the work performed. And the notorious weak resistance of drywall to dampness and moisture.

After a while, my friends developed cracks on the plasterboard slopes. Now they are very sorry that they did not immediately put plastic slopes. So we will not consider drywall slopes due to the high probability of their destruction in the near future.

Plastic slopes from single-sided sandwich panels and from double-sided sandwich panels

The first option will not suit us, since it does not have the necessary rigidity. Wide slopes of this material can bend, although they look good. The second method is good and in appearance is no worse than solid-sheet slopes 10 millimeters thick. Possesses good characteristics - reliability, rigidity, easy to clean, color fastness.

Note!

Material from double-sided sandwich panels can be easily used when installing the slopes of plastic windows in panel houses, where the slope width is from 12 cm.With no less success, they are suitable for work in brick houses with slopes up to 60 cm wide.

And the last of the methods we are considering is the installation of window slopes made of plastic sheet, having a thickness of 8 to 10 millimeters. Very high quality slope 10 mm thick, which has high thermal insulation properties. Insulated with mineral wool. The disadvantages include the high cost of the material compared to all previous methods. Although the price, as I found out, is about the same level as that of double-sided sandwich panels.

I chose for myself the trimming with slopes from Belgian sheet (of the highest quality) plastic 10 mm thick. The fact is that a year ago they installed slopes for plastic windows from this material in the kitchen and living room (with a balcony). And I was very pleased. Therefore, when I now changed the windows in two bedrooms, I settled on a similar method. Having previously considered all the others. Decorating the slopes with plastic cost me about $ 190 for two windows. I considered it inappropriate to save $ 40 with a tangible difference in quality.

The price included all the necessary materials and work for the installation of plastic slopes, namely: removal of the old plaster layer; alignment and completion of potholes that appeared after dismantling the old window frame; filling the external assembly seam with plaster, as well as the seam under the windowsill and the ebb; thermal insulation of plastic slopes with mineral wool and leveling of the window opening; installation of plastic slopes itself; sealing all seams formed at the joints of plastic materials and slopes with a waterproof sealant; well, garbage collection, respectively.

And finally, what else I would like to draw your attention to. Highly important point is the qualification of the craftsmen, whose hands will be used to install the slopes on plastic windows. It makes sense to pay a little more here, but in the end you will save on nerves and decent quality.

Talk to different craftsmen from different companies or private traders. From a conversation with them, one can already develop, if not a 100%, then quite adequate idea of \u200b\u200btheir professionalism. True, in this case you should be more or less savvy, at least within the framework of this article.

Look at your friends at the quality of plastic slopes in their houses and apartments, listen to reviews. One of my acquaintances, for example, had the plastic bent outward, became convex and wavy. The so-called "masters" "came up with the idea" to lay construction foam under the sheets of plastic slopes during work. And the plastic itself was cheap and thin there.

In general, the guy's windows were mutilated. And he, a modest fellow, did not even call them to account. As soon as I saw the "quality" of the slopes of some of my friends, I immediately made sure that this did not happen to me. I approached the choice of masters very scrupulously, which saved myself from unnecessary headaches. After all, it is known that it is better to prevent than to cure) As a result, this article appeared, based on personal experience.

And you can judge the quality and aesthetic properties of my plastic slopes from the photographs. I am satisfied.

source: http://zastroykin.ru/

The fashion for plastic windows is not diminishing. On the contrary, such designs are gradually gaining more and more popularity. However, such an installation is usually accompanied by the need to manufacture window slopes, without which the windows will be blown out, and the room will not delight you with its appearance.

The fashion for plastic windows is not diminishing. On the contrary, such designs are gradually gaining more and more popularity. However, such an installation is usually accompanied by the need to manufacture window slopes, without which the windows will be blown out, and the room will not delight you with its appearance.

As usual, the owners are faced with the question of choosing materials for the slopes. It must be said that the choice is quite limited, since a natural selection of the most suitable materials for these purposes has already taken place. In the article we will list what you will have to choose from, as well as talk about the pros and cons of these materials.

Contrary to popular belief about the dangers of plastic, we dare to assure you that modern plastic panels intended for indoor use are completely harmless to humans. Do you use a lot of things made of acrylic, silicone, leatherette?

Useful advice!

Useful advice!

Plastic does not emit any toxins or fumes around itself, therefore it is also environmentally friendly. And the fact that it does not allow air to pass through, do not bother you. Plastered and painted drywall also does not let it through.

A huge plus of plastic slopes is their practicality. Plastic does not get dirty, does not lose its color, caring for it is extremely simple. Slope installation work is done in record time. Slopes throughout the apartment are usually made in 1 day. This is the cleanest method of making slopes of all of the above.

The only "dirty" moment is stuffing wooden blocks on the walls from the side of the window or doorway. As a minus, you should pay attention to the relatively high cost of such slopes. Consider the cost of the plastic itself, plastic profiles, wooden beams and hardware.

source: http://remont-ekspert.ru/

Finishing the slopes of plastic windows

Everyone who at least once changed old windows for new ones, or installed them in a new building, knows what slopes are. This is the inner and outer part of the window opening, which is damaged when dismantling the old window and requires immediate repair after installing a new one.

Leaving this stage "for later" is not worth it: while you are swinging, the polyurethane foam that was used when installing windows under the influence of ultraviolet radiation will become unusable and lose its properties. Moreover, in the solidified state during heating / cooling, it changes in volume by 5-10% and is quite capable of "crushing" itself.

As a result, a gap forms between the frame and the foam over time, negating all sealing efforts. Secondly, the foam is not a waterproofing material, so it will constantly gain moisture, which, after freezing, will destroy the foam itself. In general, the slopes must be put in order even if the aesthetic side of the matter does not bother you too much.

Plastic slopes (PVC slopes)

This is a method involving the rapid transformation of unpresentable slopes into ideal ones.

Plastic slopes come in several varieties. These are slopes from plastic panels, universal plastic slopes and slopes from "sandwich" panels.

Plastic panels

Plastic panels are the simplest, cheapest and not the best quality slopes. These panels are made of lightweight, hollow plastic inside. Such a slope is not very durable, it is they who are most often used in industrial premises and offices.

Their popularity is growing from year to year. What are the advantages of plastic slopes compared to traditional drywall slopes?

Their popularity is growing from year to year. What are the advantages of plastic slopes compared to traditional drywall slopes?

The fact is that RTD plastic slopes are easy to install, which ensures ease and speed of installation. Slopes are assembled from plastic, as from construction kit parts, with practically no dust.

If you decide to replace the windows, but do not plan to make repairs in the room, then we would recommend you plastic slopes, they are the best fit.

Plastic slopes look modern and stylish. They are best suited for VEKA plastic windows. The joints of slopes and walls will be securely and neatly hidden by a special edging. Plastic slopes are very convenient to use, in particular, because in case of contamination they can be washed with water and soapy water.

RTD slopes:

- Length 6000 mm

- Width 600 mm

- Thickness 10 mm

- Rib thickness 0.52 mm

Advantages of RTD Plastic Slopes:

- the plastic slope panel is made of high quality rigid PVC;

- does not require varnishing, additional painting and special care;

- environmentally friendly, non-toxic material ensures the safety of human health and the environment;

- retains its color under the influence of ultraviolet rays for a long time;

- goes well with such finishing materials like: PVC corners, F-profile, slope casing + casing cover and other materials for interior decoration of slopes;

- ideally matches the color shade with products from white PVC profiles;

- allows convenient and easy installation.

source: http://otlichnie-okna.ru/

Options for finishing window slopes

A plastic window installed in accordance with all the rules will not be able to fully perform its functions if the finishing of the slopes is made poorly. This is due to the fact that the window opening is the main source of moisture penetration into the room, extraneous sounds and drafts.

This finishing method also provides for a number of finishing works that need to be done for a more aesthetic appearance.

The main types of slopes:

Slopes can be placed both inside and outside the building. The presence of both is very important to protect the premises from the effects of various factors. Finishing is done by plastering, using drywall or plastic.

Plastering and plasterboard finishing are laborious and not always effective. To completely complete these works, even a professional will need, in addition to certain experience and knowledge, at least a week. These two methods have a number of significant drawbacks that can affect the qualities required for the entire structure.

Finishing slopes with plastering

Market building materials offers a large number of plasters with heat-insulating, waterproofing, antimicrobial effect. Despite this, over time, plaster slopes tend to lose color and crack. Insufficient thermal insulation capacity contributes to the fogging of glass. The plastering process itself takes place in several stages. Each layer must not only be evenly applied, but also wait until it dries completely.

Plasterboard slopes

Plasterboard trim can increase the level of thermal insulation. To do this, it is necessary to carry out preliminary insulation using special materials, for example, cotton wool. In addition, the surface is repeatedly primed and painted. It may take more than a week in time.

Decorating slopes with plastic

Currently, experts in the field of PVC structures use only plastic slopes. This is due to the advantageous features of the material, which allow achieving maximum thermal insulation, waterproofing, sound insulation, practicality and aesthetics of the appearance of the room.

Modern plastic finishing of window openings is carried out by installing sandwich panels.

Plastic slopes as the best solution for keeping warm in the room.

The slopes produced using this technology can indeed be called warm. This is achieved due to the design features of the sandwich panels themselves. They consist of several plastic sheets and expanded polystyrene, polyurethane or mineral wool.

Note!

Thanks to the inner layer, thermal conductivity values \u200b\u200bare minimal. External plastic panels are responsible for protection from various external factors. They are constantly exposed to temperature changes, climatic precipitation and sunlight.

The joint work of all layers of sandwich panels gives the slopes such advantages as:

- Beneficial effect on the creation of an optimal indoor climate

- Resistance to mechanical and chemical stress

- Sound and heat insulation

- Resistant to atmospheric precipitation and UV radiation

- Long service life - over 35 years

- Ease of installation

- Easy maintenance and easy cleaning of surfaces from dirt

It is possible to install sandwich panels in a short period of time by contacting specialists or by yourself. To carry out the installation on your own, a small set of tools and the availability of special installation materials are enough. Using plastic as a material for slopes, it is possible not only to avoid up to 40% of heat loss, but also to additionally protect the assembly seams and prevent condensation.

Using plastic slopes, you can make the window not only functional, but also aesthetic. There are various color and texture solutions for sandwich panels. They can be made under a tree, have a classic white color, matte or glossy. How diverse the choice of models will be depends on the manufacturer.

Using plastic slopes, you can make the window not only functional, but also aesthetic. There are various color and texture solutions for sandwich panels. They can be made under a tree, have a classic white color, matte or glossy. How diverse the choice of models will be depends on the manufacturer.

Depending on the basic requirements, warm slopes with a thickness of 10 to 24 mm can be used. Editing is carried out at right angles or at dawn. For the convenience of subsequent repair, platbands are installed. They allow you to change the wallpaper at any time and make the joints invisible.

The decision on which method will be used to work on the formation of warm and functional slopes must be made before the main installation of the window. In the event that the finishing will be done by plastering or using drywall, you need to thoroughly prepare for protracted construction work and the purchase of auxiliary materials. Companies that install PVC windows rarely use these methods.

Therefore, the masters will need to look for themselves. If you opted for plastic sandwich panels, then their order must be carried out together with the entire PVC structure. In this case, the sandwich panels can be installed together with the window.