External cladding of a wooden house. The main methods of exterior decoration of a wooden house

Finishing wooden house from the outside it is carried out for decoration and to provide a heat-insulating and protective function.

Finishing options

There are many options exterior decoration wooden house.

- Siding. When decorating a house from the outside with siding, metal siding, wood or vinyl material is used. It has a different design, copies wood or stone wall covering. Siding is made in the form of type-setting long panels with a lock fastening. They are fixed in a vertical or horizontal position.

- Brick. Decorating a wooden house from the outside with bricks will give the building a special monumentality. This solution allows the installation of additional layers of insulation between the wall and the brick. Popular finishing colors are red, white, sand. For cladding, figured, embossed bricks are used to frame various zones and create a beautiful exterior.

- Panels. Finishing a wooden house from the outside with brick or stone panels gives the building an aesthetic appearance and protects it from negative influences. The panels are large sheets that are easy to assemble. This material is completely moisture resistant.

- Block house. Finishing the house from the outside with a block house allows you to give the structure the appearance of a wooden frame, cladding under natural wood makes the building more comfortable and attractive.

- A rock. or perfect for finishing columns, corners, basements, window openings outside a wooden house. A wide variety of stone decoration amazes with the unique beauty of textures, colors, combinations with each other.

- Lining. Decorating a wooden house from the outside is often done with clapboard or panels with imitation of a bar.

In the first case, the boards are fastened with an overlap or end-to-end through a system of grooves. There are two main types of it - classic and euro lining. The difference lies in the processing of the material. The lining is of a higher quality, has a smooth coating, ideal geometry, and absorbs less moisture. Decorating the house with clapboard gives it an aesthetic appearance that attracts with coziness and warmth.

Imitation of timber - facing material in the form of wide and thick panels. Such a structure looks like a massive one, built from a real solid bar with a flat surface and rounded edges.

High-quality exterior decoration of the house with modern materials will provide wall insulation, protect the building from dampness and temperature changes. The clad facade looks stylish, neat and elegant.

Widespread popularity wooden houses due to the use of the most environmentally friendly material that allows you to create a home that is safe for human health. Natural origin and the ability to "breathe" dictate the need for facing on such buildings. Finishing a wooden house from the outside significantly extends its service life, and also performs a decorative function.

The need for outdoor decoration

Exterior wall decoration in a wooden house protects the building from a number of negative factors environment:

1) mechanical damage;

2) fungus, mold;

3) UV radiation;

4) atmospheric precipitation;

5) temperature drops;

6) loss of precious heat;

7) fire.

Along with practical protection functions exterior decoration allows you to give a wooden house an aesthetic, stylish look and prolongs its life. Sometimes, finishing materials can mask minor construction defects.

Variety of finishing materials

Facade decoration can be done with a variety of materials:

- block house made of wood or metal;

- facing types bricks;

- clinker thermal panels;

- siding (metal, vinyl).

In addition to the listed materials, wooden private houses can be sheathed with porcelain stoneware or painted with persistent paints.

Speaking about the popularity of finishing materials, we can state the fact - for finishing the walls of suburban real estate, the leader is the vinyl type of siding. PVC panels are an excellent option for cladding old houses and new buildings.

Plastic compares favorably with the traditional cladding material - lining in several parameters:

1) long-term preservation of appearance - more than 2 decades;

2) a wide range of temperature differences - from -50 ° C to + 60 ° C;

3) absolute moisture resistance;

4) ease of maintenance;

5) not susceptible to decomposition and decay;

6) light weight is not an additional load on the foundation.

80% of vinyl siding is the main component - polyvinyl chloride, the remaining 20% \u200b\u200bis distributed between additives:

- dyes;

- plasticizers;

- protective ingredients;

- other components.

When comparing wood and vinyl siding, the latter has the following advantages:

1) endurance - the ability to withstand the scorching sun and bitter frost;

2) fire resistance - does not ignite and does not contribute to the spread of fire;

3) serves as a ventilation layer, does not allow condensate to accumulate;

4) perfectly keeps its shape - does not form cracks, chips, roughness;

5) excellent appearance even after 20, 30, 40 and more years;

6) ease of installation - no special equipment required.

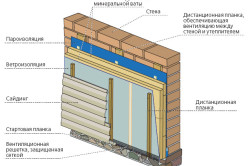

Exterior vinyl siding is applied to the batten, which creates an additional air gap to retain heat and ensure regular ventilation of the building. Bars for the lathing must be impregnated with antiseptics to prevent the development of mold and mildew inside the structure.

Siding trim requires compliance with some rules:

- when fixing the panels in their places, you cannot fix them tightly. The gap between the screw head and the siding must be at least ½ mm. The reason is possible temperature deformations finishing material;

- the location of nails or screws is strictly in the center of the oval hole for fasteners. This will avoid distortions of the panels during operation.

In addition to vinyl finishing material, other options are used for the facade. This is about metal types siding - panels are made of steel or aluminum. Compared to PVC, the metal finish has its advantages:

1) higher resistance to mechanical stress;

2) a wide color palette;

3) high degree of fire resistance;

4) execution finishing works possible in any weather.

But the master must remember that metal siding (especially steel) has a significant weight, which means it will put pressure on the foundation. Therefore, most often such finishing is done for non-residential, industrial or auxiliary buildings (garages, hangars, warehouse complexes, etc.).

Externally, the block house is a wooden board that looks like a log. The material has found wide application in the field of facade decoration. The block house looks especially organically on the outer walls of wooden houses (the photo can be viewed on the company's website).

The advantages of the finishing material are weight:

- great view;

- easy installation;

- good noise and heat insulation;

- long service life;

- masking all the unevenness of the walls.

Along with a lot of positive aspects, a wooden block house has the following disadvantages:

1) the price of the material is higher when compared with siding;

2) wooden parts need careful treatment with antiseptics;

3) low degree of fire safety.

Decorating a wooden house with a block house allows you to imitate the facade of a Russian log hut. The popularity of eco-style in architecture has been growing lately, so there are enough supporters of the use of a block house.

For the installation of a block house, a crate is used, between the cells of which you can lay insulation or additionally arrange a ventilated layer. The installation of the material starts from the bottom, the panels are conveniently connected by the “thorn-groove” mechanism.

- on self-tapping screws;

- using galvanized nails;

- clays.

To decorate the corners, special corner strips are used, which experienced builders fix on the frame with liquid nails.

A novelty in the market of finishing materials is a block house made of metal, devoid of many of the shortcomings of a wooden fellow:

- fire resistance;

- attractive price (1.5-2 times lower than wooden);

- durability;

- resistance to mold and mildew.

Externally, a block house made of metal is practically indistinguishable from natural natural material.

Brick cladding

With the advent of facing bricks on the market, the material began to be used for facing wooden houses. Today, brick products are distinguished by a wealth of color and texture solutions. Traditional types of bricks (silicate, ceramic building) are inferior in many respects to facing blocks.

Facing brick has a lot of advantages:

1) durability;

2) excellent thermal insulation;

3) the visual appeal of the facade;

4) resistance to mechanical and atmospheric influences;

5) fire resistance.

But there are some nuances in the matter of finishing facades with bricks. It must be remembered that the mass of blocks is very different from plastic siding and creates additional load on the base of a wooden house.

A common mistake homeowners make is turning to bricklayers to brick a wooden house. The fact is that when carrying out these works, you need to understand well the thermal physics of walls made of wood. The result of the work of illiterate specialists is the slow decay of the wooden frame and the subsequent deformation of the entire structure.

It is only necessary to trust the cladding of a wooden house to professionals who have repeatedly performed this work and are fluent in technology.

Clinker panel is an alternative to traditional brick for cladding facades. Replacing the material allows you to speed up the process and reduce its cost. For the production of clinker panels, a complex technology is used that combines specifications clinker materials and high thermal insulation parameters.

The main characteristics of the finishing material:

- minimal hygroscopicity;

- low vapor permeability parameters;

- resistance to mechanical stress;

- excellent strength;

- ability to withstand UV rays;

- good heat insulator;

- durability of operation (more than 50 years);

- ease of care;

- material safe for human health and the environment.

The list of advantages of clinker panels makes the material very popular in finishing works. The insulation of many models is expanded polystyrene or polyurethane. The material is fixed on a wooden crate, the thickness of the beams of which must be decent (the weight of 1 panel can reach 19-19.5 kg). For sealing the seams and masking the caps of the self-tapping screws in the clinker thermal panels, a special grout is used. As a result of the work, a complete illusion of brickwork is created.

Application for finishing porcelain stoneware facades

Porcelain stoneware tiles are often used for facing the facades of wooden houses.

The material has the following properties:

1) high strength parameters;

2) fire resistance;

3) endless possibilities for choosing colors, textures and shapes;

4) various assembly technologies (fastening to rustic materials, clamps, glue);

5) resistance to frost;

6) immunity to UV radiation.

The main components used in the production of porcelain stoneware are only natural materials: feldspar, kaolin, quartz sand,dyes and white clay. The absence of synthetic ingredients allows the finishing material to be classified as environmentally friendly.

Fastening of porcelain stoneware slabs to a wooden facade is carried out on a pre-assembled profile frame. Without fail, a layer of heat insulator is laid under the profile and a gap is left for ventilation.

The cost of a porcelain stoneware facade is superior to other cladding options, but it has also served homeowners for decades.

Painting the exterior walls of wooden houses

As an option for the exterior decoration of a wooden house, painting the facade is.

The finished coating has the following characteristics:

- protection of external walls from precipitation;

- resistance to sunlight;

- protection of a wooden frame from temperature changes.

The exterior walls of the house can be painted with different paintwork materials, available on the market in a wide range:

- water-soluble PVA;

- styrene-butadiene paint;

- acrylic based emulsion;

- oil-acrylate;

- azure and various varnishes;

- oil-alkyd;

- pentaphthalic enamels (PF), etc.

In order for the painted coating to last longer, it is important to carefully prepare the surface of the walls: clean it from old paint, dirt and dust; prime, etc. Painting is done manually (with a roller or brush) or using a spray gun, spray gun.

External finishing of the facade: the main stages

The cladding of the outer walls of a wooden house is carried out in stages:

1) settlement operations. At this stage, planning of all materials is carried out - which and in what volume must be purchased, including consumables (nails, screws, screws, etc.). If the finishing is carried out on an old wooden house, at this stage the state of the foundation is analyzed - if necessary, the cost of strengthening it is calculated;

2) the choice of the materials themselves so that they are organically combined with the architecture of the house and the style of the site;

3) preparation of the facade: cleaning, if necessary - priming, puttying. At this stage, the crate is mounted (for many types of finishing materials);

The tree remains one of the most demanded building materials... There is nothing surprising. The wood is absolutely safe material... And houses built from conifers even have antiseptic qualities.

Wood is the best and most environmentally friendly material for building and decorating a house. However, it darkens over time and loses its attractive appearance.

But over time, the building's condition deteriorates. In this regard, external finishing of a wooden house will be required.

House cladding materials

Facing works have several goals. First of all, wooden house protects against the negative effects of precipitation, sunlight, temperature extremes and mechanical damage.

Secondly, the exterior of a wooden house prevents the growth of fungal bacteria and mold.

Thirdly, the cladding work contributes to the insulation of the house, which is an important factor in modern conditions, when energy prices are constantly rising.

And finally, fourthly, exterior decoration improves the aesthetic appeal of the house and prolongs the operational period. load-bearing structures building.

Home decoration is necessary in order to protect the house from the negative effects of precipitation, mechanical damage, fungus, mold, etc.

There are several options for cladding a wooden house. Various materials can be used to accomplish this work:

- siding;

- facing brick;

- block house;

- clinker thermal panels;

- porcelain stoneware;

- paints and varnishes.

The most popular materials for the exterior of a wooden house are facing bricks and siding.

Decorating the house with bricks gives the house an attractive appearance and additional strength.

This technology is very labor intensive. But there are three cases when a wooden house just needs to be faced with brickwork:

- When the building is constructed of poor quality timber and looks unattractive.

- During the construction of a frame-panel house.

- When a wooden house has already served for many years, and you need to increase its rigidity.

The latter option is the most common. When cladding old houses, you can face the problem of small eaves. Brickwork can be located directly at the edge of the overhang, which will cause rainwater to enter into and onto the facing material. Such conditions will significantly reduce the life of the brick. It is recommended to start facing work if the length of the overhangs exceeds 35 cm.

For the implementation of brickwork, the following materials and tools are needed:

- brick;

- roofing material;

- rolled membrane;

- concrete mixer;

- anchors;

- fittings;

- cement;

- sand;

- trowel;

- 2-3 buckets;

- shovels;

- roulette;

- plumb line;

- level;

- formwork boards;

- ax;

- fishing line;

- nails;

- a tool for joining seams;

- wooden pegs.

For facing a wooden house with bricks, you must have a high-quality foundation. If there are wide walls of the base, then you can use them. In any case, for high-quality brickwork, it is necessary that the minimum width of the base is 20 cm. This is necessary for arranging a ventilation gap and laying heat-insulating material.

A strip foundation is made around the entire perimeter of the house with a depth of 0.3-0.4 m and a width of 0.2 cm. For this, formwork is created from unedged boards. Its height should be equal to the distance from the lower crown of the structure to the soil.

The bottom of the dug trench is covered with a layer of sand 5 cm thick. Roofing material is laid on top of the compacted sand with an overlap on the walls of the trench. The formwork is half filled with concrete, in which the reinforcement is laid. The second half of the formwork is poured. After 28-30 days, masonry work can be carried out.

House insulation is optional. But waterproofing work is necessary. The best option for a wooden house would be to use a roll-up membrane.

The brickwork is connected to the wall using anchors made of galvanized wire. Anchors should not be rigid. Otherwise, when the soil shrinks, the brickwork may be disturbed. 4 anchors are installed on 1 m² of the wall. Additional anchors are installed at the corners of a wooden house, along the perimeter of window and door openings.

Anchors are driven into a wooden wall with a hard end. Brick laying can be done both on the edge and on a wide surface. Before masonry work, roofing material is laid on the foundation. Start laying bricks from the corner. The quality of all work depends on the correct laying of the first row.

For free circulation of air in the lower rows between load-bearing wall and holes are left with the facing material. For this purpose, the vertical joints placed every two bricks are not filled with concrete. Similar holes are made at the points of contact with the roofing material. This creates a ventilated facade.

The nuances of cladding a building with siding

More common is the technology of finishing a wooden house with siding. But it also assumes compliance with a number of requirements. The most important condition for carrying out work is the presence of completely dried wood. For this reason, it is forbidden to install siding on a new wooden house.

To clad the house with siding, we need:

- siding;

- insulation;

- stepladder;

- metal profiles;

- screwdriver;

- bulgarian;

- hacksaw;

- roulette;

- level;

- scissors for metal;

- ruler;

- square;

- a hammer;

- sharp knife;

- awl;

- pliers;

- self-tapping screws.

All elements that will interfere with the fastening of the panels are removed from the facade: lanterns, drainpipes, cornices, grilles and other details. After that, they are engaged in the creation of a frame from wooden bars or metal profiles. Despite the wooden base, the second option is more acceptable. Metal profiles have the same dimensions, and choosing identical bars is more difficult.

Cladding work begins near door and window openings.

That is, in areas where there is a maximum load for the panels. This will move the siding joints away from these places.

The lowest point is determined on the wall. 5-10 cm are measured from it and a horizontal line is marked, at the level of which the starting profile is installed. Installation of external and internal profiles is carried out in the corners of the building. The edging of the openings is carried out. To fix the siding, J-profiles are mounted near the cornice. Now you can start assembling the panels.

The first row of panels fits into the starting strip. Subsequent panels are overlapped with offset seams. It is strictly forbidden to tighten the siding strongly, as as a result of temperature changes it will swell and collapse.

Self-tapping screws are screwed into special holes on the panel. And you do not need to screw them all the way in. The siding panels should move horizontally. To fix the last panel, a finishing profile is attached to the top of the wall. The panel is slightly trimmed and the trimmed side is mounted into the inner part of the profile.

Simultaneously with the installation of siding, experts recommend conducting thermal insulation work. Various materials can be used as insulation for a wooden house: polystyrene, expanded polystyrene, mineral wool. When choosing a thermal insulation material, the climatic conditions of the area and the features of the building's operation are taken into account.

Finishing a wooden house from the outside is the final stage of construction and is considered one of the key types of work carried out after the construction of the main building.

This is due to the fact that it includes not only the aesthetic aspect, but also performs a protective function. In addition, it should be borne in mind that any decoration of a wooden house from the outside will create an additional load on the foundation. Therefore, it is recommended to plan the future wall cladding in advance, even at the stage of designing a wooden house.

It is important to note that all wooden houses are subject to natural shrinkage, in this regard, the work on the facade cladding must be carried out only after the completion of this process.

Functions of external decoration of a wooden house

According to its functional tasks, the external decoration of a wooden house performs several main functions, namely:

- aesthetic and decorative - with the help of cladding, you can give an attractive and elegant appearance to the building;

- protective - external finishing significantly reduces the degree of aggressive effects of climatic conditions on the structure, and in particular high humidity, sunlight, temperature changes, precipitation and other things;

- fire-fighting - fire-retardant finishing materials and special means of wood processing can significantly reduce the risk of fires and the speed of its spread in the event of a fire;

- heat and sound insulation - installation of cladding and insulation materials can increase the heat-saving qualities of the whole house by an order of magnitude and reduce the level of noise exposure.

The technology of carrying out work on facing the walls of the house

In practice, two methods of laying finishing materials are used:

- "Dry method" - finishing materials are attached using dowels, bolts, screws, nails, etc .;

- "Wet method" - an adhesive base is used for wall cladding installation.

By design features, the external facade finish is divided into two types:

- ventilated - with the help of the crate installed on the wall, a gap is created between the finishing element and the facade;

- deaf (non-ventilated) - facing materials are fixed to the wall close to each other without a gap.

Based on the performance properties of any wood, a ventilated facade is more preferable for a wooden house. This is due to the fact that without free space, the tree will cease to "breathe" and mold may appear if wet condensation forms between the wall and the cladding.

Types of finishing materials for wooden buildings

To give protective properties and a modern appearance, it is recommended to clad the facade of houses on all wooden buildings. An exception to this rule are houses made of rounded logs. In this case, it will be enough to process the logs with special fire-retardant and moisture-resistant compounds, having previously polished them beforehand.

Despite the fact that facing materials are quite diverse, the following types are most used for exterior decoration of wooden houses:

- The lining is a simple cladding wooden board that is fixed with connecting grooves. This type of finish is easy to install and low cost. With proper processing, the lining does not rot, it is durable and easily covered with paint. In addition, it provides additional thermal insulation protection.

- Siding is the most famous finishing material, the basis for the production of which can be vinyl, metal, wood, cement and PVC. It is easy to install, has many colors, does not require constant maintenance and perfectly protects the house from mechanical damage. The metal version provides excellent external fire protection.

- Block house is one of the varieties of lining. FROM outside can be made in the form of a rounded log or imitate a wall of noble wood species. Such panels are installed using a "thorn-groove" fastening.

- Imitation of timber - this type is considered no less popular than siding. The basis for such a cladding of a house is made up of planed boards that imitate a wall made of timber. Fastened using the thorn-groove technology. Does not involve large financial costs. It is allowed to use this type of decoration as elements for the interior arrangement of the room.

- Wall panels - the fashion for this type of decoration came from Europe. and it can be called the most modern material for facade cladding. These finishing materials have a distinctive feature, which consists in the fact that they are ready-made finishing elements that are produced by gluing massive plates from different types of wood. Subsequently, they are coated with varnish or paint.

Choosing the option of exterior decoration of a wooden house

There are no strict rules for choosing a cladding, and it all depends on personal preferences and wishes, however, experts recommend taking into account the type of wooden structure before purchasing finishing materials.

So, in particular, if the house was built using rounded logs, then the structure itself does not imply additional facade cladding. In this case, as noted above, it is enough to cover the logs with a protective layer with the desired color palette... The same is recommended for laminated veneer lumber houses.

But as for the frame-panel houses, for such buildings, external finishing work will be necessary. This is due to the fact that it is quite problematic to process the wooden elements of a frame-panel house with a special protective coating. The most preferable option in this case would be the exterior decoration of a wooden house with siding or wall panels... The use of other types of cladding is also not excluded.

Cladding a wooden house

The technological process for the installation of facing materials on the walls of a building can be divided into several stages:

- planning and calculating the amount of materials;

- choice of cladding material;

- preparation and treatment of walls with special protective compounds against fire, moisture and fungus;

- installation of battens on the facade;

- if necessary, the insulation is laid;

- installation of finishing material on the facade;

- adjustment drainage system and roofing.

Correct planning and high-quality laying of external cladding will significantly increase the durability of a wooden house and give it a beautiful and finished appearance.

More articles on this topic: